Lockout tagout devices are devices used to prevent the unexpected energization or startup of machinery or equipment during maintenance or repair work. LOTO devices are essential to workplace safety, and they help prevent workplace injuries and accidents.

The two primary types of lockout tagout devices are lockout devices and tagout devices. Lockout devices physically prevent the machinery or equipment from being turned on, while tagout devices provide a warning that the machinery or equipment should not be turned on.

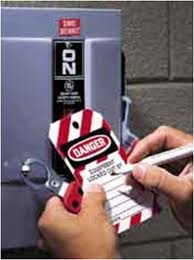

Examples of lockout devices include lockout hasps, which can lock out multiple workers from a single energy source, and circuit breaker lockout devices, which prevent electrical circuits from being turned on. Examples of tagout devices include warning tags and warning signs that inform workers that maintenance or repair work is in progress.

When implementing LOTO procedures, it is essential to follow the guidelines set out in OSHA's (Occupational Safety and Health Administration) Control of Hazardous Energy standard (29 CFR 1910.147). This standard sets out the requirements for using LOTO devices to ensure the safety of workers during maintenance or repair work.

Visit our Lockout Tagout Training Page

Different types of Lockout Tagout Devices

Several types of lockout tagout devices are designed to help prevent the unexpected energization or startup of machinery or equipment during maintenance or repair work. Some common types of LOTO devices include:

Lockout hasps: A lockout hasp is a device that can lock out multiple workers from a single energy source. It is designed to fit over the energy-isolating device and has multiple holes for inserting padlocks.

Circuit breaker lockout devices: Circuit breaker lockout devices are designed to prevent electrical circuits from being turned on. They are typically made of durable plastic or metal and are designed to fit over the circuit breaker switch, preventing it from being turned on.

Valve lockout devices: Valve lockout devices are designed to prevent the opening or closing of valves during maintenance or repair work. They are designed to fit over the valve handle, preventing it from being turned.

Plug lockout devices: Plug lockout devices are designed to prevent the plugging in or unplugging of electrical plugs during maintenance or repair work. They typically consist of a plastic or metal cover that fits over the electrical plug, preventing it from being plugged in.

Cable lockout devices: Cable lockout devices are designed to prevent the movement of machinery or equipment during maintenance or repair work. They typically consist of a cable threaded through the equipment, with the ends of the cable secured with a padlock.

Warning tags: Warning tags are designed to provide a visual warning to workers that maintenance or repair work is in progress. They are typically made of durable plastic or paper and have a warning message printed on them.

It is important to choose the appropriate LOTO device for the specific type of machinery or equipment being worked on and to follow the guidelines set out in OSHA's (Occupational Safety and Health Administration) Control of Hazardous Energy standard (29 CFR 1910.147). Proper use of LOTO devices can help prevent workplace injuries and accidents.

Lockout hasps

Lockout hasps are lockout tagout (LOTO) devices that lockout multiple workers from a single energy source. They are designed to fit over the energy-isolating device, such as a circuit breaker or valve, and have multiple holes for inserting padlocks.

Lockout hasps are typically made of durable materials, such as steel or aluminum, and can be used in various industrial settings. For example, they are instrumental when multiple workers work on the same machinery or equipment. Each worker can attach their padlock to the hasp, preventing the machinery or equipment from being turned on until all workers have completed their work.

To use a lockout hasp, each worker attaches their own padlock to the hasp and then removes the key, preventing the hasp from being opened. Once all workers have completed their work, they can remove their padlocks and the lockout hasp, allowing the machinery or equipment to be turned on.

Circuit breaker lockout tagout devices

Circuit breaker lockout devices are a type of lockout tagout (LOTO) device used to prevent the unexpected energization of electrical circuits during maintenance or repair work. They are designed to fit over the circuit breaker switch and prevent it from being turned on.

Circuit breaker lockout devices come in various shapes and sizes to fit different types of circuit breakers. They are typically made of durable materials, such as plastic or metal, and can be secured with a padlock to prevent unauthorized removal.

To use a circuit breaker lockout device, the device is first attached to the circuit breaker switch. This can be done by sliding the device over the switch and securing it in place. The device should be locked with a padlock, and the key should be kept by the authorized person performing the maintenance or repair work.

Once the circuit breaker lockout device is in place and locked, the circuit breaker cannot be turned on, preventing the flow of electrical energy to the equipment being worked on. This helps ensure the safety of workers and prevents electrical accidents.

Valve lockout devices

Valve lockout devices are a type of lockout tagout (LOTO) device designed to prevent valves' opening or closing during maintenance or repair work. They are used to immobilize the valve handle or wheel so that it cannot be turned.

Valve lockout devices come in various shapes and sizes to fit different types of valves. They are typically made of durable materials, such as steel or aluminum, and can be secured with a padlock to prevent unauthorized removal.

To use a valve lockout device, the device is first attached to the valve handle or wheel. This can be done by sliding the device over the handle or wheel and securing it in place. The device should be locked with a padlock, and the key should be kept by the authorized person performing the maintenance or repair work.

Plug lockout devices

Plug lockout devices are a type of lockout tagout (LOTO) device used to immobilize an electrical cord or wire plug, preventing the flow of electricity to the equipment being worked on. They are typically used when unplugging the equipment is not possible or practical.

Plug lockout devices come in various shapes and sizes to fit different types of plugs. They are typically made of durable materials, such as plastic or metal, and can be secured with a padlock to prevent unauthorized removal.

To use a plug lockout device, the device is first attached to the plug of the electrical cord or wire. This can be done by inserting the plug into the device and securing it in place. The device should be locked with a padlock, and the key should be kept by the authorized person performing the maintenance or repair work.

Cable lockout devices

Cable lockout devices are a type of lockout tagout (LOTO) device used to immobilize large, complex machinery with many energy sources. These devices consist of a flexible steel cable that can be threaded through multiple energy sources, such as electrical switches, valves, or disconnects, and locked in place with a padlock.

Cable lockout devices come in various lengths and thicknesses to fit different machinery and energy sources. They are typically made of durable materials, such as steel or nylon, and can be secured with a padlock to prevent unauthorized removal.

To use a cable lockout device, the cable is first threaded through the energy sources to be immobilized. The cable ends are then looped together and secured with a padlock. The key to the padlock should be kept by the authorized person performing the maintenance or repair work.

Warning tags

Warning tags are a type of lockout tagout (LOTO) device used to communicate safety information and warnings about the energy sources of equipment undergoing maintenance or repair. These tags are typically made of durable materials, such as plastic or cardboard, and are brightly colored for high visibility.

Warning tags indicate the equipment's status and provide instructions and safety warnings to workers. They typically feature printed messages, such as "Do Not Start," "Do Not Touch," or "Under Maintenance." They may also include information about the authorized personnel responsible for the equipment, the date and time of the LOTO procedure, and contact information for the maintenance department.

Warning tags are typically attached to LOTO devices with a strong nylon or plastic tie, such as lockout hasps or cable lockout devices. The tag should be securely fastened to the LOTO device, and the tag should not be able to be removed without damaging it.