Industrial Electrical Power

What is a Short Circuit

A short circuit occurs when electrical current takes an unintended path of very low resistance, resulting in excessive current flow. This electrical fault can cause overheating, sparks, equipment failure, fire hazards, and power outages, making electrical protection essential in modern systems.

What is a Short Circuit?

A short circuit (SC) is a common electrical issue that occurs when an unintended connection between two points in an electrical system allows excessive current to flow.

✅ A short circuit is an abnormal connection that allows electricity to bypass its intended path.

✅ It happens when conductors touch directly, creating excessive current flow.

✅ Short circuits can result in equipment failure, fire hazards, and system shutdowns.

This dangerous condition can damage electrical devices, create fire hazards, and even lead to electrocution. Understanding the nature of short circuits is crucial for preventing, identifying them early, and taking safe corrective action.

Power System Protection Courses

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

Causes of a Short Circuit

There are many ways a short circuit can develop, but almost all of them involve an unintended electrical path. Insulation failure is one of the most common causes of this issue. When the protective covering around a conductor breaks down due to heat, age, or mechanical damage, it allows electricity to escape and take a new route. Once current finds a low-resistance path, the short circuit occurs.

Another frequent cause is a wiring fault. Loose connections, poorly installed terminals, or damaged receptacles can cause two conductors to come into contact with each other. Environmental conditions, such as water leaks or high humidity, can also compromise insulation and create paths for electricity to flow directly to ground or between phases. Even mechanical issues, such as a nail driven through a wall into a cable or rodent damage to wires, can trigger short circuits in homes and businesses.

In industrial and utility systems, causes can be even more complex. Overloaded motors, failing transformers, or external conditions like lightning strikes can all lead to sudden short circuits. These situations highlight the importance of designing systems that can withstand not only normal loads but also the unexpected flow of fault current during emergencies. To understand how engineers maintain electrical system safety, explore our electrical protection channel, which covers essential devices and best practices.

Types of Short Circuits

Not all short circuits are identical. Each type has different consequences and requires specific protective measures.

A line-to-line short circuit occurs when two energized conductors in a system come into contact. This often results in a large surge of current that can melt conductors or destroy connected equipment.

A line-to-ground short circuit happens when a live conductor touches a grounded surface or object. Because the earth itself becomes part of the unintended path, this type of electrical fault can be especially dangerous in homes and workplaces.

More severe conditions include symmetrical faults, in which all three phases in a three-phase system are shorted together. These faults are relatively rare but produce the highest levels of current overload, requiring very robust protective devices. In contrast, asymmetrical faults, where only one or two phases are involved, occur more frequently but still require fast-acting protection to minimize damage.

Understanding these types is crucial for engineers who design protection systems, as each type produces different fault current levels and requires careful calculation to ensure that breakers, fuses, and relays operate correctly. One important safeguard against dangerous wiring faults is AFCI protection, which helps prevent electrical fires caused by arc faults. For a deeper insight, see our guide on arc fault circuit interrupter protection devices, which detect and stop arcing conditions.

Testing and Identifying a Short Circuit

Identifying a short circuit early is critical to preventing serious damage. One of the first signs may be flickering lights, frequent tripping of breakers, or blown fuses. Burning smells, discoloured outlets, or unusual warmth around receptacles can also indicate that a wiring fault or unintended electrical path is present.

Electricians use a variety of tools to confirm short circuits. Insulation resistance testing can detect when conductors have degraded coverings that allow leakage to occur. Fault current analysis and relay coordination studies are employed in larger facilities and power systems to predict the likelihood of short circuits and to verify that protective devices will respond correctly. Infrared inspections are another common method, allowing technicians to spot hot spots caused by current overloads before they escalate into fire hazards.

By regularly testing and monitoring electrical systems, faults can often be found before they develop into full short circuits, protecting both equipment and human safety.

Protective Devices and Safety Measures

The best defence against the dangers of a short circuit is a well-designed system of protective devices. Circuit breakers are the most common solution in both residential and industrial systems. They are designed to automatically disconnect power when fault current exceeds safe limits, preventing further damage. Different circuit breaker types are designed to protect against short circuits and overloads in specific applications.

Fuses perform a similar role. When subjected to excessive current, the thin strip of metal inside a fuse melts, breaking the connection and stopping current flow. Although fuses must be replaced once they have operated, they remain a reliable form of short circuit protection in many systems.

Ground fault circuit interrupters (GFCIs) are specifically designed to protect people by detecting leakage currents to ground, shutting off power before electrocution can occur. Arc-fault circuit interrupters (AFCIs) protect against electrical arcs, a common source of house fires. In industrial systems, more complex devices, such as protective relays and current-limiting fuses, are used to isolate faults and protect transformers, motors, and switchgear.

Together, these devices create multiple layers of safety. When properly coordinated, they ensure that only the smallest possible section of a system is disconnected during a fault, minimizing downtime and preventing large-scale outages.

Real-World Examples of Short Circuits

Short circuits occur everywhere electricity is used. In homes, a common example is when an appliance cord is damaged and the exposed wires come into contact, creating a direct connection between conductors. In such cases, breakers or fuses usually trip immediately, but not before sparks or heat may appear.

In industrial environments, a failing motor winding can create an unintended electrical path, resulting in a massive surge of current. Without properly rated protective devices, this type of electrical fault can destroy equipment worth thousands of dollars.

On the utility level, power lines struck by lightning often create line-to-ground short circuits. The fault current generated can be enormous, sometimes requiring entire sections of the grid to shut down until the protective relays isolate the problem. These examples demonstrate that short circuits are not merely a theoretical issue, but a real-world hazard that affects systems of every size.

Dangers of Short Circuits

The consequences of a short circuit are immediate and severe. The excessive current generates intense heat, which can melt insulation, deform conductors, and ignite surrounding materials. In many cases, electrical fires start because a breaker or fuse was improperly sized or failed to operate quickly enough.

Arc flashes are another danger. When a short circuit creates an arc, the sudden release of electrical energy can cause an explosion, blinding light, or even physical injury. Workers exposed to such events face life-threatening risks, which is why strict safety standards are in place in workplaces.

Electrocution is also a concern. If a short circuit allows current to flow through a person’s body, even brief contact can be fatal. These risks underscore the importance of accurate fault current calculations and the careful installation of protective devices.

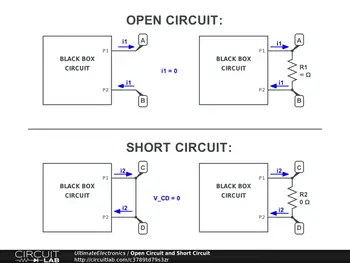

Short Circuit vs. Open Circuit

It is important to distinguish between a short circuit and an open path. In a short circuit, the current flows through an unintended path with low resistance, leading to dangerous current overloads. In contrast, an open path occurs when the connection is broken, preventing any current from flowing.

An open route may cause inconvenience, such as a light not turning on, but it does not present the same immediate dangers as a short circuit. By comparison, a short circuit represents a complete failure of the system’s ability to regulate current safely, which is why it demands urgent attention.

Understanding what a short circuit is, along with its causes, types, and dangers, is essential for maintaining safe electrical systems. By using protective devices like breakers, fuses, GFCIs, and AFCIs, and by regularly inspecting and testing wiring, you can reduce the risk of electrical faults that lead to hazardous short circuits. Whether in a home, factory, or power grid, addressing these risks promptly ensures not only the protection of equipment but also the safety of humans. For engineers conducting system studies, our page on short circuit analysis provides an explanation of methods for assessing risks and planning protective measures. A solid understanding of fault current calculation is essential for designing effective short circuit protection systems.

Related Articles

Test Your Knowledge About Software and Apps!

Think you know Software and Apps? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Latest IEP Content

Industrial Electrical Safety Explained

Industrial electrical safety ensures OSHA compliance through lockout-tagout, arc flash mitigation, NFPA 70E procedures, PPE selection, grounding and bonding, risk assessment, and preventive maintenance to control electrical hazards in factories and process plants.

What Is Industrial Electrical Safety?

Industrial electrical safety controls hazards using standards, procedures, PPE, and engineered safeguards.

✅ Apply NFPA 70E arc flash risk assessment and PPE boundaries

✅ Implement LOTO procedures for de-energization and verification

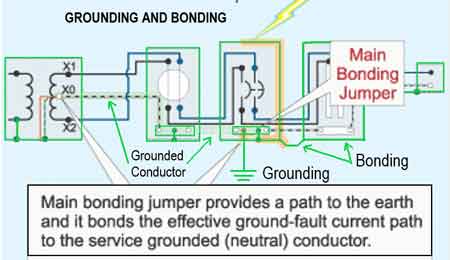

✅ Verify grounding, bonding, and GFCI protection in wet locations

Industrial Electrical Safety.

On average, every 30 minutes a worker is so severely injured on the job that they require time off to recover. and approximately three million electrical professionals are engaged in work where lockout/tagout procedures should be used each day. It is these sheer numbers that contribute to electrical-related violations being in the top 10 of OSHA violations. The two that continue to make the top 10 are electrical wiring methods and general electrical requirements. For clarity on employer duties, see the OSHA framework outlined in OSHA electrical safety guidance for practical context.

Visit Our AF Course Page:

electricityforum.com/electrical-training/arc-flash-training

The National Institute for Occupational Safety and Health (NIOSH) identify four main types of electricity-related injuries:

- electrocution

- electric shock

- burns

- falls

Understanding these categories helps teams apply procedures to protect against electrocution that are tailored to specific tasks.

To avoid injury or to mitigate injury it si important to ensure employees are properly trained and qualified for the job. A few safety tips to remember to help avoid injuries include:

- Isolate equipment from energy sources

- Test circuits and conductors every time before coming in contact

- Identify potential electric shock and arc flash hazards

- Only work on de-energized equipment and conductors

- Always lockout/tagout and properly ground equipment before you begin working

- Treat all equipment as live until lockout/tagout, testing and grounding procedures have been implemented

- Always wear proper Personal Protective Equipment (PPE) and clothing in areas where potential electrical hazards and arc flash situations are present

- Use insulated tools whenever possible

Embedding these practices into daily routines supports compliant electrical safety work that minimizes exposure to energized parts.

There are more than 300 electrocutions and some 4,000 injuries in the workplace each year directly related to electrical hazards. Although not the leading cause of workplace injuries, electrical hazards cause serious injury and death, and are costly to the employer. Often overlooked, grounding is a major component of electrical safety, as outlined in the OSHA manual in part 1910.305, subpart S, Wiring Design. Organizations can benchmark programs against electrical safety requirements to close gaps and improve accountability.

Good grounding creates a low-resistance path so electrical charges will flow safely away from the work area, so they won’t cause harm. Normally grounding is built in as a permanent part of the electrical system but should never be taken for granted. These principles align with proven electrical safety workplace practices that emphasize verification and maintenance.

Proper tagout procedures (of electrical boxes and equipment) are a major component of any safety program. “Tagging out” is in reference to locking circuit breakers or start-up panels, and attaching warning tags so that no other worker throws the switch by mistake. Clear labeling and documentation are essential elements within broader electrical safety procedures that prevent inadvertent energization.

In Canada, the Canadian Standards Association established in 2006 CAN/CSA-Z1000-06, Occupational Health and Safety Management Systems (OHSMS) as the national standard. Included in section 4.4.2 and 4.4.3 are the preventive and protective measures, and the application of such. These include:

- elimination of the hazard;

- identifying the nature and extend of the hazards and risk;

- the degree of hazard and risk reduction required; and

- applying recognized standards, codes, and best practices in the industry sector.

Adopting such systems fosters a culture of electrical safety where risk assessments inform training and continuous improvement.

Related Articles

Electric Motor Efficiency

Electric motor efficiency measures how well motors convert electrical energy into mechanical power with minimal losses. High efficiency improves performance, saves electricity, reduces operating costs, lowers heat, and supports sustainability in industrial power systems.

What is Electric Motor Efficiency?

Electric motor efficiency is the ratio of useful mechanical output to electrical input, indicating the motor's ability to convert electrical energy into mechanical energy.

✅ Reduces wasted electricity and lowers costs

✅ Extends motor lifespan and reliability

✅ Supports energy efficiency and sustainability

Electric Motor Testing Training

Request a Free Training Quotation

Why Electric Motor Efficiency Matters

Focusing on the efficiency of electric motors, such as single-phase and DC motors, is essential for both economic and environmental reasons. By understanding the factors that affect performance and implementing measures to enhance output, businesses and industries can enjoy long-term energy savings and contribute to a sustainable future.

In an environmentally conscious world, energy efficiency is paramount. Single-phase and DC motors, which convert electrical power into mechanical power, play a crucial role in various industries. Optimizing their performance can lead to significant energy savings and promote sustainability. This article explores ways to enhance motor efficiency and provide valuable insights for improvement.

Efficiency Standards and Classifications

Motor efficiency is often defined by international standards. IEC efficiency classes (IE1 through IE4) and the NEMA Premium label in North America establish benchmarks for performance. For example:

-

IE1 = Standard efficiency

-

IE2 = High efficiency

-

IE3 = Premium efficiency

-

IE4 = Super-premium efficiency

Many regions, including Canada, the USA, and the EU, require minimum performance standards (MEPS). Using motors that meet or exceed IE3/NEMA Premium ensures compliance and long-term savings.

Quantitative Examples and Losses

Typical industrial induction motors operate at:

-

80–85% efficiency for small (<1 kW)

-

90–93% for mid-range (10–100 kW)

-

95–97% for large industrial (>200 kW)

Losses include:

-

Copper losses: ~30–40% of total losses

-

Iron/core losses: ~20–30%

-

Mechanical losses (friction/windage): ~10–20%

-

Stray load losses: ~10%

These values highlight the importance of targeting multiple factors to maximize performance.

How to Calculate Efficiency

Motor efficiency can be expressed as:

η = (Output Power ÷ Input Power) × 100

Where:

-

Output Power = Torque × Speed × (2π/60)

-

Input Power = Voltage × Current × Power Factor

In the field, optimization can be estimated using power meters, torque transducers, and dynamometers. Laboratory testing provides more precise measurements, but in-service monitoring is increasingly available through smart sensors.

Table 1. Typical Motor Efficiency by Size and Power Rating

| Motor Size / Rating | Typical Efficiency Range | Notes / Applications |

|---|---|---|

| Small (<1 kW) | 75–85% | Used in appliances, fans, small pumps; less efficient due to proportionally higher core & friction losses. |

| Medium (10–100 kW) | 88–93% | Widely used in industrial pumps, compressors, conveyors; good balance of size and efficiency. |

| Large (>200 kW) | 95–97% | Heavy industry, power plants, steel mills; best efficiency due to lower relative losses. |

| Premium efficiency (IE3) | 92–96% | Meets NEMA Premium/IE3 standards; typical in modern industrial systems. |

| Super-premium efficiency (IE4) | 94–98% | State-of-the-art; required in some regions, common in advanced manufacturing and EVs. |

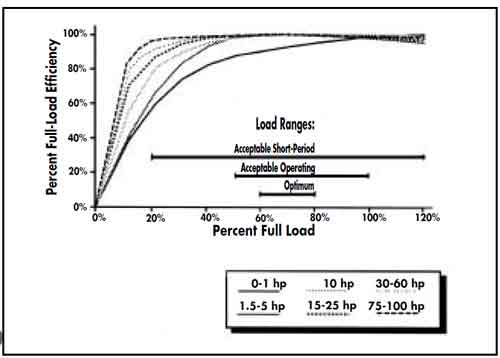

Behavior Under Load

Efficiency is highest near rated load (75–100%). At light loads, copper and core losses dominate, reducing efficiency. Overloaded motors run hotter, which accelerates wear and shortens their lifespan. An efficiency curve typically shows a peak around 80% load, with significant drops below 50% load or above 110%. Effective electric motor control systems ensure they run at the right load and speed, a key factor in maximizing optimization and minimizing wasted energy.

Thermal Effects and Cooling

Heat is a significant hindrance to efficiency. Winding resistance increases with temperature, raising copper losses. Magnetic materials also lose performance when overheated. Effective cooling—through the use of fans, liquid cooling, or enhanced thermal design - keeps them within optimal operating ranges and prevents performance degradation. The fundamentals of how an electric motor works reveal why losses occur and how performance can be measured and improved in real-world settings.

Material and Design Innovations

Modern high-efficiency motors use advanced materials such as:

-

High-grade silicon steel laminations to reduce core losses

-

Rare-earth permanent magnets for synchronous motors

-

Soft magnetic composites for innovative topologies

Emerging designs like axial-flux motors and switched reluctance motors are gaining popularity for their compact size and high efficiency, particularly in EVs and renewable systems. Engineers can boost performance by optimizing electric motor design, focusing on materials, winding configurations, and innovative topologies.

Monitoring and Degradation Over Time

Even efficient motors lose performance as they age. Bearing wear, misalignment, insulation degradation, and rotor/stator imbalances all contribute to reduced performance. Predictive maintenance tools—such as vibration analysis, thermal imaging, and online condition monitoring—help detect issues before they cause major energy or reliability losses.

Table 2. Breakdown of Typical Losses

| Type of Loss | Share of Total Losses | Description / Impact |

|---|---|---|

| Copper (I²R) losses | 30–40% | Heating in the stator and rotor windings due to resistance. |

| Iron / Core losses | 20–30% | Hysteresis and eddy current losses in the magnetic core. |

| Mechanical losses | 10–20% | Bearing friction, windage, and other moving parts. |

| Stray load losses | ~10% | Additional losses from leakage flux, harmonics, and load imperfections. |

| Additional degradation | Variable | Caused by aging, misalignment, insulation breakdown, or poor maintenance. |

Cost, ROI, and Lifecycle Analysis

Although high-efficiency motors have a higher upfront cost, payback periods are typically short. For example, upgrading to a premium-efficiency type may recover its cost within 1–3 years through reduced electricity bills. Considering the total lifecycle (purchase, operation, maintenance, and energy use), efficient devices deliver the lowest long-term costs.

Regulations and Incentives

Governments worldwide encourage performance upgrades through rebates, tax credits, or compliance requirements. In North America, DOE and NRCan regulations require minimum efficiencies for certain classes. The EU’s Ecodesign directive enforces IE2/IE3 as the minimum standard. These policies accelerate adoption of energy-saving technologies.

Practical Measures to Improve Efficiency

Our guide on efficiency opportunities through motor maintenance explores how predictive strategies and proactive care deliver measurable energy savings.

Implementing the following measures can improve electric motor performance for single-phase and DC motors:

-

Proper maintenance: Regularly inspect and maintain bearings, windings, and insulation to minimize losses.

-

Power factor correction: For AC motors, use correction capacitors to reduce reactive power.

-

Upgrade to high-efficiency: Replace old units with IE3 or NEMA Premium-rated motors.

-

Optimize sizing: Ensure the motor matches the load to avoid under- or over-loading.

-

Variable speed drives (VSDs): Adjust motor speed to match load demand.

-

Brushless DC: Improve efficiency by eliminating brush friction and commutator losses.

Many improvements in electric motor maintenance directly enhance performance by reducing friction, preventing wear, and extending the operational life of the motor.

Comparisons and Use Cases

Efficiency strategies vary by motor type:

-

AC induction motors: Benefit from VFDs and improved design.

-

Synchronous motors: Offer higher efficiency and better power factor.

-

Brushless DC motors: Deliver efficiency with reduced maintenance.

-

Switched reluctance motors: Rugged and efficient for high-speed applications.

Applications include pumps, fans, conveyors, compressors, and electric vehicles—each with unique performance considerations. Installing variable frequency drives is one of the most effective methods to optimize electric motor efficiency by matching speed to load requirements.

Emerging Trends

Digitalization and Industry 4.0 are transforming motor efficiency. Smart controllers, IoT-enabled sensors, and real-time monitoring enable continuous optimization. Wide-bandgap semiconductors (such as SiC and GaN) in inverters enhance performance in motor drives. Regenerative braking systems in EVs showcase how modern control strategies maximize energy recovery and sustainability.

Electric motor efficiency is critical for reducing energy consumption, lowering costs, and supporting sustainability. By considering standards, design innovations, thermal management, and lifecycle economics, industries can achieve significant gains. With regulatory support, advanced materials, and digital monitoring, the path toward higher performance and greener energy use is clear.

Related Articles

Incident Energy Explained

Incident energy is the heat released during an arc flash, measured in cal/cm². It defines arc flash boundaries, sets PPE levels, and ensures NFPA 70E compliance. Reducing incident energy lowers burn risk, improves safety, and supports safe electrical practices.

What is Incident Energy?

Incident energy is a critical metric used to measure the thermal energy released during an arc flash incident, expressed in calories per square centimetre (cal/cm²).

✅ Measures arc flash thermal energy in cal/cm²

✅ Determines proper PPE level and arc flash protection boundaries

✅ Used in NFPA 70E and CSA Z462 arc flash studies and risk assessments

Request a Free Training Quotation

This value determines the appropriate level of personal protective equipment (PPE) required to prevent serious injuries such as second- and third-degree burns. Accurate calculations of incident energy exposure are the foundation of any effective arc flash safety program, enabling employers to establish arc flash boundaries, apply compliant warning labels, and enforce safe work practices.

A reliable arc flash study must include an incident energy evaluation to ensure worker safety and compliance with both NFPA 70E and CSA Z462 standards. For step-by-step calculations and case studies, check our incident energy analysis page.

Why Incident Energy Matters

Arc flash incidents are among the most dangerous electrical hazards. Thousands of incidents occur annually, causing hundreds of serious injuries and fatalities. Beyond personal harm, arc flash events lead to costly downtime, equipment loss, and legal liability.

By defining incident energy, safety professionals can:

-

Protect workers from severe burns.

-

Ensure compliance with NFPA 70E and CSA Z462.

-

Reduce insurance costs and operational risk.

Understanding and applying these principles is crucial for creating safer workplaces.

Arc flash incidents pose a serious threat to electrical workers, often resulting in severe arc flash injuries such as second- and third-degree burns.

Within this arc flash boundary, the use of personal protective equipment PPE is not optional—it’s essential.

See our Arc Flash PPE article for more information.

Implementing effective OSHA electrical safety protocols starts with conducting a formal hazard analysis that considers system voltage, fault current, and clearing time.

How Incident Energy Is Calculated Using IEEE 1584

To determine the amount of incident energy that can be released during an arc flash, electrical professionals rely on the IEEE 1584-2018 standard. This calculation takes into account a range of system and environmental variables.

Accurate assessment depends on understanding the following core inputs:

-

Arcing Current: The actual current that sustains the arc during the fault event.

-

System Voltage: The operating voltage of the equipment under evaluation.

-

Available Fault Current: The maximum short-circuit current supplied to the arc.

-

Clearing Time: How quickly protective devices interrupt the fault.

-

Working Distance: The distance between the arc and the worker, typically 18 inches.

These calculations are essential components of a full arc flash risk assessment and are often conducted using specialized software and data from the facility’s arc flash study (short circuit and coordination studies).

Real-World Example: How Incident Energy Affects PPE

Consider a 480V system with a potential fault current of 30,000 amps. Using IEEE 1584, the resulting incident energy may reach 9.6 cal/cm² at 18 inches.

At this level:

-

Workers require arc-rated clothing with an ATPV rating greater than or equal to the calculated exposure (≥12 cal/cm²).

-

If clearing time is reduced, incident energy may drop below 8 cal/cm², lowering PPE requirements and improving mobility.

For a deeper understanding of how these figures are determined, please refer to our main Arc Flash Study page.

Techniques to Reduce Incident Energy

Modern facilities use design and operational strategies to lower exposure:

-

Current-Limiting Fuses: Interrupt arcs within milliseconds.

-

Arc-Resistant Equipment: Redirects blast energy away from personnel.

-

Maintenance Mode Switches: Shorten trip times during energized work.

-

Zone-Selective Interlocking (ZSI): Improves protective coordination.

NEC requirements (such as Sections 240.67 and 240.87) mandate the reduction of incident energy in certain equipment, reinforcing the importance of proactive design.

These techniques are covered in more depth in our guide to arc flash study requirements, which outlines everything employers must include in a safety study.

Compliance With NFPA 70E and CSA Z462

Both standards require incident energy evaluations as part of a complete electrical safety program. Compliance includes:

-

Labeling equipment with incident energy values or PPE categories.

-

Providing PPE based on calculated exposure.

-

Training workers to recognize and mitigate arc flash hazards.

Skipping these steps exposes companies to citations, liability, and preventable accidents.

For further guidance, see our Arc Flash Study, Arc Flash PPE, OSHA Electrical Safety, and Lockout Tagout (LOTO) resources.

Arc Flash Analysis Training

Companies that skip these steps risk citations, legal liability, and preventable injuries. Discover how to develop a compliant program with our arc flash analysis training courses designed for qualified personnel. A comprehensive electrical safety program should include regular arc flash assessments, incident energy calculations, PPE training, and strict adherence to NFPA 70E compliance standards.

Benefits of Accurate Incident Energy Evaluation

Accurate evaluation delivers:

-

Reduced risk of life-threatening burns.

-

Improved compliance and lower liability.

-

Safer, more efficient work practices.

-

Reduced downtime and insurance costs.

Incident energy isn’t just a number—it is a benchmark that shapes every aspect of electrical safety. To protect your team and comply with regulations, a full arc flash study that includes incident energy evaluation is essential.

If you're looking to build or update your safety program, start with a full arc flash study and make incident energy output a central part of your risk management strategy.

Explore More Arc Flash Topics

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.

Commissioning Numerical Relays Explained

Commissioning numerical relays ensures accurate protection settings, IEC 61850 interoperability, SCADA integration, and reliable trip logic through testing, calibration, relay configuration, CT/VT verification, firmware updates, and fault diagnostics in substations and industrial power systems.

What Is Commissioning Numerical Relays?

Commissioning numerical relays validates settings, logic, I/O, and comms to ensure correct protection and tripping.

✅ Secondary injection, end-to-end, and trip tests validate protection.

✅ Verify CT/VT ratios, polarity, wiring, and I/O mapping.

✅ Configure settings, logic, IEC 61850/GOOSE, time sync, and SCADA.

Modern numerical relays have many new features that were not available in electromechanical or analog designs such as setting groups, programmable logic and adaptive schemes. Although these features make numerical relays very powerful, they also create a need for reviewing commissioning methods. It is common practice to make changes to commissioning tests and revised documentation of relay settings. There are very few standards covering commissioning, so most methods come from experience. There are many methods that give good results. In practice, many modern devices consolidate protection, control, and monitoring in multifunction relays that require disciplined commissioning workflows.

Commissioning protective relays requires three primary tasks the relay personnel should perform:

For context, a concise overview of roles and operating principles is given in what a protective relay is which helps align test objectives.

- Calibration of the relays

- Functional test

- In-Service readings

Calibrating the relays confirms that, when voltage and/or currents appear at the relay terminals, the relay will respond according to design and set-point. The functional test confirms that when the relay contacts close, the proper breakers trip or close according to the design. The functionality of all AC and DC schemes should also be checked. Guidance on bench procedures and safety checks can be found in how to test a solid-state relay for cross-referencing techniques.

To close the loop, in-service readings are taken as soon as the equipment is placed in service and has load current flowing. In-service readings confirm that, with a given load present, the proper voltages and currents appear at the relay terminals.

Calibrating relays and functional testing must be done before the equipment is put in service. In-service readings must be taken immediately after load is on the equipment.

The equipment is not released to the dispatcher or plant operator until the in-service readings are correct.

There are other commissioning tasks important to protective relays such as testing instrument transformers, meggering control cables, confirming transformer taps, and so on. However, this paper will concentrate on calibration, functional testing and in-service reading. These areas are most affected when using numerical relays. This focus is especially important when working with complex protective relays where feature interactions can influence test scope.

Let's refer to electromechanical and solid-state relays as “traditional” and microprocessor based designs as “numerical”. Although there are significant differences in electromechanical and solid-state devices, the methods used for testing and commissioning are similar, whereas numerical relays must be approached differently.

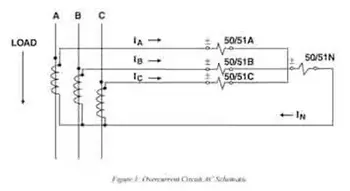

COMMISSIONING TRADITIONAL RELAYS

Let’s discuss how we would commission this traditional relay. Relay calibration is performed using the manufacturer’s instruction manual and the relay setting sheets. In our simple overcurrent example, the setting sheet would include identifying information about the station name, the feeder number, and relay model numbers. The actual setting is: . CT ratio

- 50 element current setting

- 51 element inverse time curve selection

- 51 element tap

- 51 element time dial.

This information will easily fit on one sheet of paper, and keeping copies of the setting in either hard copy or electronically is easy. For broader context on applications and types, see protective relays and how their settings are documented in practice.

The settings are put on the relays by selecting taps, adjusting dials or setting switches.

Secondary current values are then injected into the relay using a test set. Pickup of the 50 and 51 elements is checked against the setting, and adjustments are made to bring the relay within calibration limits. Timing tests of the 51 element are also made to ensure the time dial and curve settings are correct. The output contacts are monitored during these tests with an ohmmeter or test set to indicate operation.

Functional Testing, also called trip checking, is another keystone activity of commissioning. Effective trip checking relies on relay and circuit breaker coordination so that verified operations produce the intended system response.

This is not the place to cut corners. Our intent is to confirm that the protection and controls work as intended and also that they have no unintended consequences.

Making checks to ensure the design works right is called a “positive” test. Making checks to see that the design doesn’t work incorrectly is called a “negative” test.

The phase overcurrent relays will trip the breaker directly. The ground relay has a cutout switch that must be closed to trip the breaker. Each overcurrent relay is operated one-at-a time to make certain each one works. The relay contact should be forced to close with the test set instead of applying a jumper across the contact.

Targets are confirmed after each trip. Open the ground cutout switch, then attempt to trip with the ground relay; the breaker should not trip. With the ground relay trip contact still closed, turn the ground cutout switch back on and confirm that the breaker trips. This proves the cutout switch prevented tripping and not something else. These are all “positive” tests.

From: Electrical Relays, Protection & Control Handbook, Vol 5, The Electricity Forum

Related Articles

Arc Flash Levels of Protection

Arc Flash Levels of Protection define PPE categories per NFPA 70E, based on incident energy analysis and approach boundaries. They guide arc-rated clothing selection, shock protection, and safe work practices for electrical systems.

What Are Arc Flash Levels of Protection?

They are NFPA 70E PPE categories based on incident energy, defining arc-rated gear, approach boundaries, and safe work.

✅ Align PPE Category 1–4 with incident energy in cal/cm²

✅ Establish limited, restricted, and arc flash boundaries

✅ Specify arc-rated clothing, gloves, face shields, and tools

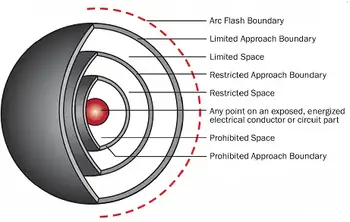

Arc Flash Levels of Protection are best understood as layers or boundaries of protection around and away from hazardous electrical equipment.

Understanding how an arc flash hazard influences boundary selection and PPE choice clarifies why layered protections are necessary in the first place.

Arc flash boundary

The arc flash boundary, or restricted approach boundary, changes depending on the potential arc flash hazard. The arc flash boundary is calculated to 1.2 calories/cm2 of incident energy. That’s the distance where a worker without appropriate PPE would receive second-degree burns. For deeper context, see how NFPA 70E guidance informs boundary calculations in practice.

Sometimes this boundary is the furthest one from the exposed equipment, other times the limited approach boundary is the furthest out. When the arc flash boundary is the furthest away, it becomes the line no one should pass without training and PPE. If the limited approach boundary is further out, then that should be treated as the line no one should pass without training and PPE. This distinction is central to arc flash protection strategies that define who may cross and under what conditions.

Limited approach boundary

Moving toward the energized and exposed equipment, you’ll find the limited approach boundary. Within this boundary, it is still possible to be exposed to a shock hazard. Appropriate PPE should be worn by qualified workers in the limited space (space between the limited approach boundary and the restricted boundary). Non-qualified workers should stay outside of this boundary unless wearing proper PPE and being escorted by a worker with specialized training.

Aligning task categories with arc flash PPE requirements helps ensure non-qualified personnel remain protected when proximity is unavoidable.

Restricted boundary

The area closest to the live, exposed equipment is within the restricted boundary. In order to pass this boundary, you must be a qualified worker with the proper training and PPE. If you need to perform work on the energized equipment, you may also need a work permit and documentation. Selecting appropriate arc flash safety equipment supports permitting decisions and safe work execution.

Arc Flash Protection first became a major area of investigation in the 1980's when in the IEEE published Transactions on "Industry Applications" there happened to appear an article authored by a Ralph Lee entitled: “The Other Electrical Hazard: Electric Arc Blast Burns.” This early investigation led several companies to realize, particularly companies from the petrochemical industry, that too many electrical workers were injured from electrical safety accidents. Consequently, several leading companies acted to create the first known set of work practices that were designed to specifically protect electrical workers who were performing electrical maintenance and service work on energized electrical equipment.

As guidance matured, enforcement through OSHA arc flash requirements accelerated adoption of consistent procedures across sectors.

Visit Our CSA Z462 Arc Flash Training Page

Visit Our NFPA 70E Arc Flash Training Page

In terms of personal protective equipment (ppe), here are the most valuable minimum arc rating levels of protection

- face shield

- required ar

- leather footwear

- hearing protection

- arc flash suit hood

- layer of arc rated ppe

- rubber insulating gloves

While petrochemical facilities were maybe the first to see the need for electrical arc flash protection, it quickly was seen that arc flash hazards apply to all electrical facilities. Although the level of incident energy released in an electrical arc flash explosion may be larger in the higher voltage ranges found in petrochemical and other industrial facilities, it meant that the large volume of medium and especially low voltage electrical equipment in industrial, commercial and institutional facilities would cause the largest number of electrical safety accidents.

Arc Flash Levels of Protection starts with preventing personal protection injuries from occurring is to turn off the electrical equipment before starting work. Standards such as NFPA 70e and CSA Z462 are intended to lay out arc flash guidelines for qualified electrical workers when de-energizing could lead to a greater hazard than leaving the power on. These arc falsh protection standards squarely place the responsibility for electrical worker safety on both employers and facility owners for making sure that safe electrical workplace standards and practices are in place to protect their workers from electrical safety accidents. Organizations can map tasks to NFPA 70E arc flash requirements to justify energized work and select appropriate controls.

The goal of these electrical arc flash protections standards, such as NFPA 70e, is to keep electrical workers free from the hazards of shock, electrocution, arc flash, and arc blast. It's important, therefore, to understand the requirements set forth in the standards for employee safety, the importance of an electrical safety program, the responsibilities of employer and employee, and the processes and best practices set forth in various industry standards and regulations.

ARC FLASH INDUSTRY STANDARDS

Four separate industry standards establish practices for the prevention of electrical explosion incidents:

OSHA 29 Code of Federal Regulations (CFR) Part 1910, Subpart S

This regulation states, in part, "Safety related work practices shall be employed to prevent electric shock or other injuries resulting from either direct or indirect electrical contacts… ." OSHA also addresses the qualification of workers exposed to electrical shock hazards and the provision for protective equipment appropriate for the work to be performed. OSHA enforces electrical arc flash protection practices and cites the NFPA requirements.

NFPA 70e, National Electrical Code

Section 110.16 requires that companies place a warning label on electrical equipment likely to consitute an electrical safety hazard. This field marking can be generic or very specific, whichever the company selects. Future revisions of the NEC standard may require more detailed information on this label.

NFPA 70e, Standard for Electrical Safety Requirements for Employee Workplaces

NFPA 70E can be considered the “how to” standard behind OSHA enforcement. It provides the detailed actions companies must take to be in federal compliance.

Specifically:

- Arc flash protection program with defined responsibilities

- Calculations for the degree of electrical safety hazard

- Arc rated personal protective equipment (PPE) for workers, such as flame resistant, arc flash suit

- Training for workers

- Tools for safe work

- Warning labels on equipment

IEEE Standard 1584, Guide for Electrical Safety Regulation

In order for the arc flash protection warning labels to carry enough information to show the danger zone for electrical safety conditions, companies must determine that area within which only qualified workers should enter—the protection boundary. IEEE 1584 provides a method to calculate the incident energy in order to specify the level of PPE required for workers.

Related Articles

Arc Flash Calculations To Determine Incident Energy

Arc flash calculations determine the incident energy and arc flash boundary to protect electrical workers. These calculations use system voltage, available fault current, and clearing time to define PPE requirements and safe working distances. Required by NFPA 70E and CSA Z462 standards.

Request a Free Training Quotation

What are Arc Flash Calculations?

Arc Flash Calculations are required to determine the incident energy level a worker could be exposed to in calories/cm².

✅ Determine incident energy levels and arc flash boundary distances

✅ Guide selection of personal protective equipment (PPE)

✅ Required by NFPA 70E and CSA Z462 to prevent arc-related injuries

This is outlined by NFPA 70e Electrical Safety Requirements for Employee Workplaces, which states, “A hazard analysis shall be done to protect personnel from the possibility of being injured by an arc flash. The analysis shall determine the Flash Protection Boundary and the personal protective equipment that people within the Flash Protection Boundary shall use.” In addition, IEEE Standard 1584, Guide for Performing Arc-Flash Hazard Calculations. For more details on how arc flash protection works, visit Arc Flash Protection standards.

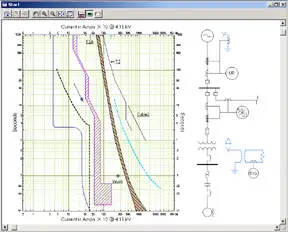

Annex D in NFPA 70E presents the same incident energy level equations as those found in IEEE Std. 1584, but the latter goes into more detail. NFPA 70E doesn't specify that the IEEE Std. The 1584 method has to be used. The incident energy level can be determined using one of the several arc-flash software programs currently available on the market.

As understanding of the arc-flash hazard has grown, several methods for calculating the hazard have been developed. Three of these methods will be examined in this section—the theoretical model, the equations and tables used in NFPA 70E and the calculation methods presented in IEEE Std 1584. Learn more about safety standards for electrical systems and arc flash by visiting Electrical Safety Tips.

Power System Protection Courses

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

In addition to these two methods, other tools are available for calculating hazard levels, including various Windows and DOS-based shortcut calculator programs, IEEE 1584-based calculators on equipment manufacturers’ websites, and equipment-specific equations. Even IEEE 1584 presents two alternate calculation methods for many situations—the general equations and the simplified equations for circuit breakers and fuses. For a given system location, one can calculate several different values for incident energy levels or for the hazard boundary distance.

While the calculations may be close to one another in many situations, this may not always be the case. How can one be sure which method produces the best results for a given situation? No single calculation method applies to all situations, but several principles may be followed to ensure that the best results are obtained in a given situation:

-

Verify that actual system conditions fall within the method’s range of applicability. Many of the available calculation methods are at least partially based on empirical equations—i.e., equations derived from test results. These equations are valid within the range of system conditions for which testing was performed, but cannot be extended to other situations with a high degree of confidence. For example, the equations in IEEE 1584 cannot be used to calculate arc-flash hazard levels at locations with a bolted fault current exceeding 10^6 kA or in a DC system. This principle is also important when using the NFPA 70e tables to assess hazard levels, as the tables are based on specific assumptions regarding available fault currents and fault-clearing times.

-

Out with the old, in with the new. Hazard analysis is a relatively new field, and as a result, the available methods have undergone significant changes as our understanding of the phenomenon has grown over the past 20 years. Newer test results, industry standards, and calculation methods are more likely to accurately represent the actual hazard levels than older methods. They should be used in preference to older methods that may be based on smaller sets of test data or may be applicable over a smaller range of system conditions.

-

Use device-specific equations rather than general equations. While the general equations in IEEE 1584 are based on lab testing over a wide range of system conditions, the testing cannot possibly accurately characterize the performance of every available protective device in every possible situation.

-

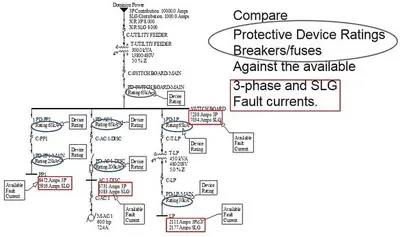

Know which device clears the fault and use realistic fault current values.

First, the engineer must determine which circuit breaker is responsible for clearing the fault. Depending on exactly where the fault initiates in the panel, any of the three devices may initially act to clear the fault. Typically, the worst-case scenario involves the fault occurring on the line side of the panel’s main circuit breaker, in which case it must be cleared by the upstream feeder device (“A”).

This breaker, which would normally be set to coordinate with device “B selectively”, should have the longest tripping time of the three devices shown for a given value of fault current. Even if the arcing fault initiates on the load side of the branch circuit breaker “C”, the fault could easily propagate to the line side of the other devices in the same enclosure. Therefore, to ensure that the calculations reflect the maximum energy level to which a worker might be exposed, the trip characteristics of device “A” should be taken into account. To explore incident energy calculations in electrical safety, read our article on Incident Energy.

What value of fault current should be considered—the available bolted fault current at the switchboard containing device “A”, or the available fault current at the lighting panel itself? Suppose that a 100 kA bolted fault current is available at the switchboard, but the panel is located 100 feet away. The impedance of 100 feet of #3/0 AWG conductor drops the available bolted fault current at the panel to approximately 28 kA.

Since the concern in this case is over arcing faults at the lighting panel, the value of bolted fault current that should be used as an input to the IEEE 1584 equations is relevant. IEEE 1584 is then used to calculate the arcing fault current level, approximately 15 kA. The device’s trip characteristics must be consulted to determine its clearing time at 15 kA. Then, IEEE 1584 is used to calculate the incident energy level and protection boundary at the panel. In some situations, the best practice may be to calculate two incident energy levels and protection boundaries for a single piece of equipment. For example, consider a lineup of 480 V drawout switchgear with a main circuit breaker and several feeder circuit breakers.

The circuit breaker cubicles are more physically separated from one another than circuit breakers are in a typical electrical panel, so propagation of a fault from a feeder to the line-side of the main would be expected to be more difficult. If a fault were to occur when a feeder circuit breaker was racked in or out, then the main circuit breaker would be expected to clear the fault. However, when the main circuit breaker is racked in or out, the upstream protective device—possibly a fuse or relay on the primary side of an upstream transformer—is called upon to clear the fault.

In this case, the upstream protective device may act relatively slowly, which could mean that workers are exposed to a much higher level of hazard when racking the main than when racking a feeder. In cases such as this, or in other situations where workers may be potentially exposed to hazards in a section of gear on the lineside of the main (i.e., in a fire pump section), more than one calculation per piece of equipment may be warranted. For information on how to determine the protection boundary in arc flash situations, check out Arc Flash Protection Boundary.

Nine Steps To Performing Arc Flash Calculations

Step 1 – Identify All Locations and Equipment for Arc-flash Risk Assessment

Step 2 – Collect Data

Step 3 – Prepare a One-line Diagram of the System

Step 4 – Perform a Short Circuit Study

Step 5 – Determine Expected Arc Current

Step 6 – Determine the Arc Time

Step 7 – Calculate Predicted Incident Energy

Step 8 – Determine the Arc-Flash Boundary

Step 9 – Document the Arc-Flash Risk Assessment

Other Arc Flash Calculation Pages

Wiring That Isn’t OSHA Certified - Understand The Risks

Wiring that isn’t OSHA certified creates serious safety hazards, violating workplace compliance standards and the National Electrical Code (NEC). Non-compliant wiring increases arc flash risks, electrical shock exposure, and fire danger, making OSHA compliance essential.

What is Wiring That Isn’t OSHA Certified?

Wiring that isn’t OSHA certified refers to electrical installations that fail to meet OSHA safety regulations and NEC code standards, putting workers and facilities at risk.

✅ Increases arc flash, shock, and fire hazards

✅ Violates OSHA and NEC electrical safety codes

✅ Compromises workplace compliance and reliability

For a refresher on core hazards tied to non-compliant wiring, see our primer on What is Arc Flash

Request a Free Training Quotation

Common OSHA Electrical Violations

Some of the most frequent electrical violations cited by OSHA include:

-

Missing covers on junction boxes or panels (29 CFR 1910.303(b)(2): installations must be neat and workmanlike).

-

Improperly used extension cords without strain relief.

-

Flexible cords run through walls, ceilings, or doors (29 CFR 1910.305(g)(1)(iv): cords cannot substitute for fixed wiring).

-

Lack of grounding conductors or mislabeled connections.

According to OSHA data, more than 1,900 citations were issued under 1910.303 and 1910.305 in 2023 alone, underscoring the common—and preventable—nature of these violations. To align wiring practices with federal rules, review OSHA Electrical Safety Standards

Temporary Wiring & Extension Cords

Temporary wiring and extension cords are frequent problem areas. OSHA and the NEC permit temporary wiring in limited situations, such as during construction, maintenance, or emergency repairs. Under 29 CFR 1926.405(a)(2)(ii)(J), cords must be hard or extra-hard usage, three-wire type, and properly protected from damage.

Improper use—such as daisy-chaining cords, running them across walkways without protection, or using them permanently instead of fixed wiring—often leads to citations. Many arc flash and shock incidents occur due to the misuse of flexible cords, making extension cord standards one of OSHA’s most heavily enforced areas. Temporary wiring risks rise when cords aren’t checked—learn how often to inspect them here: How Often Should You Inspect an Extension Cord

Training & Inspections

Electrical safety training is essential for compliance. OSHA requires employers to ensure workers can recognize and avoid hazards, even if specific training requirements are embedded across multiple standards. Training on OSHA wiring rules, NEC codes, and NFPA 70E helps reduce violations, improve inspections, and keep workers safe.

Regular electrical inspections also play a critical role. Employers should schedule audits to verify proper grounding, secure terminations, labeling of conductors, and the condition of flexible cords. Preventive inspections not only reduce the likelihood of citations but also extend the lifespan of equipment. For best-practice methods that complement OSHA enforcement, read NFPA 70E

Real-World Consequences

Failure to comply with OSHA’s wiring standards leads to fines, downtime, liability claims, and, most importantly, potential loss of life. In one real-world case, inspectors discovered temporary cords being used as permanent wiring in a food processing facility. The violations resulted in multiple OSHA citations, costly rework, and several weeks of production delays.

Wiring that isn’t OSHA-compliant creates a dangerous workplace with heightened risks of electrical hazards, equipment malfunctions, and regulatory penalties. OSHA establishes strict standards under 29 CFR 1910 and 1926 to ensure electrical safety, while the NEC and NFPA 70E provide practical guidance for maintaining compliance. Correct hazard communication depends on accurate equipment labels—see guidance on Arc Flash Labels.

Frequently Asked Questions

What Are the Risks of Using Wiring That Isn't OSHA Certified?

Using electrical systems that do not meet OSHA requirements introduces multiple hazards. Non-compliant wiring may lack proper insulation or be improperly installed, increasing the risk of electrical shock. Contact with live parts can result in severe or fatal injuries, especially where high voltage is involved.

Poorly installed wiring also creates fire hazards. Overheating conductors or loose connections can ignite nearby materials, leading to catastrophic fires. For example, an arc flash in a manufacturing plant caused severe burns to two employees when improperly spliced, non-compliant conductors failed.

Equipment failure is another risk. Wiring that does not meet OSHA and NEC standards is prone to malfunctions, leading to costly downtime. Critical components such as junction boxes, attachment plugs, caps, and lighting fixtures may fail prematurely if wiring methods are non-compliant.

How Does OSHA Certification Ensure the Safety of Electrical Systems?

OSHA compliance ensures that electrical equipment, components, and installation methods meet recognized safety standards. Proper installation includes correct grounding, labeling, and circuit protection.

Key rules include:

-

29 CFR 1910.305(a)(2)(viii): prohibits bare conductors for temporary circuits.

-

29 CFR 1910.305(a)(2)(x–xi): requires flexible cords to be protected, supported, and strain-relieved.

Qualified personnel must install, inspect, and maintain systems. Components must be listed and labeled by NRTLs. Compliance reduces the risk of shock, arc flash, and fire, while protecting workers and equipment. Verify working distances and PPE selection using the Arc Flash Boundary

What Are the Consequences of Using Non-OSHA Certified Wiring in the Workplace?

Employers using non-compliant systems face significant legal and financial consequences. Some of the most common outcomes include:

-

OSHA citations and penalties: Failing to meet OSHA’s electrical standard can lead to fines and citations. Non-certified wiring will likely be flagged during routine inspections, resulting in violations under 29 CFR 1910.

-

Increased downtime: Electrical systems that do not meet certification standards are more prone to failures. When critical systems fail, it can lead to costly downtime, interrupting production and leading to financial losses.

-

Workplace injuries or fatalities: Non-certified wiring increases the likelihood of accidents such as electrical shock or arc flash incidents, especially if the voltage of exposed live parts is involved. These incidents can cause severe injuries or even fatalities, with devastating effects for employees and liability for employers.

-

Damage to equipment: Substandard wiring can cause overheating or short-circuits, damaging expensive machinery and equipment. This leads to frequent repairs and replacements, further increasing operating costs.

How Can I Verify If My Electrical System Is OSHA Certified?

Verification involves multiple steps.

-

Ensure systems meet the requirements of 29 CFR 1910.305 covering wiring methods and installation practices.

-

Hire qualified inspectors to check circuits, grounding, labeling, and strain relief.

-

Confirm that all equipment is listed and labeled by NRTLs.

-

Schedule regular electrical inspections to identify potential issues before they escalate into more serious problems.

-

Implement lockout/tagout (LOTO) procedures to protect employees during servicing.

Employers must hire qualified personnel, maintain inspection schedules, and provide electrical safety training to remain compliant. Ultimately, ensuring wiring meets OSHA standards is not only a regulatory requirement but also a critical step in protecting workers, reducing costs, and preventing life-threatening accidents.

Related Articles

IEP News

IEP Media

IEP Articles From ET Magazine

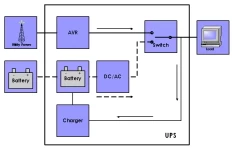

Compatibility Issues with Generator-Backed Power Systems

While both UPS systems and generators serve as safeguards against power disruptions, their integration isn't always seamless. Understanding these compatibility concerns is crucial for ensuring reliable backup power and avoiding damage to sensitive equipment.

Visit Our UPS Systems Study Course

Voltage and Frequency Stability

Generators, particularly smaller portable models, may not provide the same level of voltage and frequency stability as utility power. Line-interactive UPS units are designed to operate within a specific input voltage and frequency range. Wide fluctuations outside these tolerances can trigger the UPS to switch to battery frequently, draining reserves and potentially causing premature battery wear.

Synchronization Issues

When power from a generator is restored, there may be a phase shift or momentary mismatch in frequency compared to the UPS output. This lack of synchronization can lead to a disruptive transfer process, potentially causing a brief outage for the connected equipment.

Harmonic Distortion

Generators, especially lower-quality models or those under non-linear loads, can introduce harmonic distortion into the electrical waveform. This 'noise' in the power supply can affect the operation of sensitive electronics connected to the UPS and degrade overall power quality.

Strategies for Improved Compatibility

UPS Selection: Look for line-interactive UPS models with wider input voltage and frequency tolerance ranges. Some may offer a 'generator mode' that accommodates greater fluctuations.

Generator Quality: Whenever possible, opt for generators with better voltage regulation and lower harmonic distortion. Inverter-based generators generally provide cleaner output than conventional models.

Generator Sizing: Overloading a generator can lead to unstable output. Ensure the generator's capacity comfortably exceeds the anticipated load demand.

Isolation Transformers: In specific cases, an isolation transformer between the generator and UPS can improve compatibility by filtering out some harmonic distortion and stabilizing the voltage.

Double-Conversion UPS: A More Forgiving Solution

While the steps outlined above can improve compatibility, double-conversion online UPS systems are inherently better suited for use with generators. Here's why:

Complete Isolation: Double-conversion UPS units continuously convert incoming AC to DC and back to AC, creating a clean and regulated output regardless of generator power quality.

Wider Tolerance: These UPS systems often have wider acceptable input voltage and frequency windows, handling generator fluctuations without issue.

Considerations When Connecting a Line-Interactive UPS to a Generator

UPS Runtime: If frequent generator power deviations cause the UPS to switch to battery often, runtime will be reduced for longer outages. Assess the stability of your generator to gauge this risk.

Load Sensitivity: Less critical equipment can often tolerate generator-powered line-interactive UPS output. Highly sensitive systems might warrant a double-conversion UPS for cleaner backup power.

Neutral Bonding: Proper grounding practices are vital, especially in a generator-UPS setup. Improper neutral bonding can lead to dangerous stray currents and equipment damage.

Additional Tips

Consult Manufacturer Recommendations: Always refer to the instructions for your specific UPS and generator for guidance on compatibility and best practices.

Regular Testing: Periodically test the switchover between the generator and UPS power under load. This helps identify potential issues and ensures backup systems work as intended when needed.

Integrating line-interactive UPS systems with generators requires attention to power quality and synchronization. While choosing suitable equipment and implementing mitigation strategies improves compatibility, double-conversion UPS systems offer superior inherent resilience against generator power fluctuations. Organizations can design robust power protection schemes that ensure uninterrupted operation even during extended outages by carefully considering backup power needs and equipment sensitivity.

Line-Interactive UPS in Scalable IT Infrastructure

In the evolving landscape of IT infrastructure, reliable and flexible power solutions are paramount. Scalable line-interactive Uninterruptible Power Supply (UPS) systems provide an essential service to growing IT networks by adapting to increasing power demands without the need for complete system overhauls. This adaptability ensures that businesses can expand their IT capabilities while maintaining protection against power interruptions and fluctuations.

Visit Our UPS Systems Study Course

Scalability and Its Importance

Scalability in a UPS context refers to the ability to increase the UPS capacity to handle higher loads as demand grows. This is particularly crucial for businesses experiencing rapid growth or those planning for future expansion. The scalable nature of certain UPS systems allows for the addition of more power modules within the same infrastructure, thereby accommodating growth without significant downtime or large-scale replacements.

Advantages of Scalable UPS Systems

Cost Efficiency: Implementing a scalable UPS system is cost-effective over time. Businesses can invest in what they need today, knowing that the system can grow with their requirements. This staged investment helps manage cash flow better compared to investing in a large system upfront.

Reduced Downtime: The modular design of scalable UPS systems allows for expansions and upgrades to be performed with minimal impact on ongoing operations. This is vital for maintaining high availability and reducing the risk of downtime during upgrades.

Enhanced Flexibility: With scalable systems, IT managers can customize the UPS to meet the exact needs of their network, adjusting for power load, redundancy requirements, and runtime. This flexibility also extends to maintenance and servicing, as individual modules can be serviced or replaced without shutting down the entire system.

Long-term Reliability: Scalable UPS systems are designed to accommodate future technology changes and increases in demand. This foresight ensures that the UPS system remains reliable and effective over a longer period, thereby protecting the IT investment as the business landscape evolves.

Implementation Considerations

When planning to implement a scalable UPS system, several factors need to be considered:

Initial Assessment: Accurately assessing current power needs and future growth projections is crucial to selecting a UPS with appropriate scalability options.

Space Planning: Scalable UPS systems require strategic placement as expansions will necessitate additional space. Planning for this during the initial setup phase is essential.

Budget Allocation: While the initial cost of a scalable UPS may be higher than that of a fixed-capacity system, the long-term savings and benefits often justify the investment.

In the dynamic landscape of IT infrastructure growth, the scalability of line-interactive UPS systems presents a significant advantage. By enabling organizations to match power protection to current needs while retaining expansion capabilities for the future, scalable UPS solutions ensure reliable power, optimized investment, and minimal disruptions during inevitable periods of growth.

Scalable line-interactive UPS systems represent a smart choice for growing IT networks, offering a flexible, reliable, and cost-effective solution that grows alongside business needs. As IT infrastructure becomes increasingly critical, investing in a UPS system that can adapt to changing demands is an essential strategy for future-proofing IT operations and ensuring continuous power protection. This approach not only supports operational continuity but also aligns with the strategic growth objectives of modern businesses.

Securing Critical Infrastructure: The Role of Line-Interactive UPS

UPS (uninterruptible power supply) systems are essential for protecting critical infrastructure in healthcare and finance. They provide backup power in the event of a power outage, ensuring that sensitive equipment and data are protected. Line-interactive UPS systems are a popular choice for these applications, offering a number of advantages over other types of UPS systems.

Visit Our UPS Systems Study Course

Benefits of Line-Interactive UPS Systems

Line-interactive UPS systems offer a number of benefits over other types of UPS systems, including:

Lower cost: Line-interactive UPS systems are typically less expensive than other types of UPS systems, making them a more cost-effective option for businesses on a budget.

Smaller size: Line-interactive UPS systems are also smaller than other types of UPS systems, making them ideal for applications where space is limited.

Lower maintenance: Line-interactive UPS systems require less maintenance than other types of UPS systems, making them a more hassle-free option for businesses.

Types of Line-Interactive UPS Systems

There are two main types of line-interactive UPS systems: standby and online. Standby UPS systems only provide power when the primary power source fails, while online UPS systems provide continuous power, even during power outages.

Standby UPS systems are typically less expensive than online UPS systems, but they also offer less protection. They are a good choice for applications where the risk of a power outage is low.

Online UPS systems are more expensive than standby UPS systems, but they offer more protection. They are a good choice for applications where the risk of a power outage is high, such as hospitals and data centers.

Performance of Line-Interactive UPS Systems

The performance of a line-interactive UPS system is determined by a number of factors, including:

Power output: The power output of a UPS system is measured in VA (volt-amps). It must be sufficient to power the equipment it is protecting.

Runtime: The runtime of a UPS system is the amount of time that it can provide power during a power outage. The runtime of a UPS system is determined by the size of its battery.

Efficiency: The efficiency of a UPS system measures how much power it loses during conversion. A more efficient UPS system will lose less power and be more cost-effective to operate.

Technical Considerations

There are a number of technical considerations that must be taken into account when selecting a line-interactive UPS system, including:

Input voltage: The input voltage of a UPS system is the voltage of the power source that it is connected to. The input voltage of a UPS system must be compatible with the voltage of the power source.

Output voltage: A UPS system's output voltage is the power it supplies to its connected equipment. It must be compatible with the voltage of the equipment it is protecting.

Frequency: The frequency of a UPS system is the rate at which it converts power. The frequency of a UPS system must be compatible with the frequency of the power source.

Across the healthcare and financial sectors, where the consequences of downtime range from inconvenient to life-threatening or financially devastating, line-interactive UPS systems play a silent but vital role. Their ability to provide clean power, instant backup, and facilitate safe shutdown procedures acts as an indispensable insurance policy for critical infrastructure. As power grids evolve and technologies advance, the integration of UPS protection will remain deeply intertwined with maintaining resilience and reliable service delivery in these vital sectors.

Battery Advancements and the Impact on Line-Interactive UPS

Advancements in Battery Technology and Their Impact on Line-Interactive UPS

Line-interactive uninterruptible power supply (UPS) systems play a crucial role in ensuring power continuity for sensitive electronic equipment. Serving as a safeguard against power disruptions, these systems seamlessly switch to battery backup during outages, preventing data loss, equipment damage, and downtime. Recent advancements in battery technology, particularly lithium-ion batteries, have significantly influenced the capabilities and performance of line-interactive UPS systems.

Visit Our UPS Systems Study Course

Lithium-ion: The Emerging Choice

Lithium-ion (Li-ion) batteries, widely known for their use in laptops and electric vehicles, are increasingly finding their way into UPS systems. Here's how they stand out:

Higher Energy Density: Li-ion batteries pack more energy into a smaller and lighter form factor compared to lead-acid counterparts. This translates to space-saving UPS units or more runtime within the same footprint.

Longer Lifespan: Li-ion batteries boast more charge/discharge cycles than lead-acid batteries. This could mean less frequent battery replacements over the lifetime of the UPS system, reducing maintenance costs.

Faster Recharge Times: Li-ion batteries generally recharge faster, contributing to quicker recovery times between outages.

Efficient Operation: Reduced internal resistance leads to greater efficiency in charging and discharging, thus minimizing energy losses.

Considerations and Trade-offs

Cost: Currently, Li-ion-based UPS systems typically carry a higher initial price tag compared to those using lead-acid batteries. However, the total cost of ownership over time may be comparable or even favorable due to their longevity and lower maintenance.

Management Complexity: Li-ion batteries sometimes require more sophisticated battery management systems (BMS) for safe and optimal operation.

Safety: Certain Li-ion chemistries, if mishandled, have greater potential for thermal runaway than traditional lead-acid batteries. Reputable manufacturers prioritize robust design and safety measures in their Li-ion UPS units.

Other Battery Advancements

Enhanced Lead-Acid Batteries: Developments like Thin Plate Pure Lead (TPPL) and Absorbed Glass Mat (AGM) technologies have improved lead-acid battery performance in areas like cycle life, recharge times, and tolerance to temperature fluctuations.

Alternative Chemistries: Flow batteries, sodium-ion batteries, and more offer unique characteristics potentially relevant to specific UPS use cases.

The Impact on Line-Interactive UPS

The integration of advanced battery technologies into line-interactive UPS designs brings about notable implications:

Compact Designs: Smaller batteries open up possibilities for more streamlined and space-efficient line-interactive units, particularly valuable in edge computing and cramped network closets.

Increased Reliability: Longer battery lifespan and resilience towards environmental conditions enhance UPS system reliability overall.

Extended Runtimes: Depending on the application, advanced batteries may unlock longer backup times on smaller line-interactive units.

Eco-Friendliness: Li-ion batteries have the potential for greater recyclability than lead-acid options, minimizing environmental impact at end-of-life.

Choosing the Right Battery Technology

The optimal battery choice for your line-interactive UPS depends on several factors:

Criticality of the Load: For highly critical applications, the added longevity and performance of Li-ion batteries often justify the cost.

Space Constraints: Where installation space is extremely limited, the compactness of Li-ion solutions becomes a major advantage.

Environmental Conditions: If the UPS is in a less temperature-controlled environment, the robustness of newer lead-acid technologies or some advanced options might be preferable.