Fault Current Calculation Explained

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

Fault current calculation is crucial for ensuring electrical safety, conducting short-circuit analysis, and designing systems effectively. It determines available fault current at any point in a power system to ensure protective devices function correctly and prevent equipment damage.

What is fault current calculation?

Fault current calculation is the process of determining the maximum current that can flow during a short circuit, ensuring system protection and compliance with electrical standards.

✅ Ensures accurate short circuit analysis

✅ Supports protective device coordination

✅ Improves electrical system reliability

It plays a critical role in ensuring the safety and reliability of electrical systems. Properly calculating and understanding the current that flows during electrical faults, such as short circuits, helps in selecting the appropriate protective devices, ensuring the protection of electrical equipment, and preventing hazardous incidents. This article will examine the process of fault current calculation, its implementation, and the significance it holds for ensuring electrical safety and effective system design. Engineers often combine calculations with a short circuit analysis to predict how electrical faults will behave under different system conditions.

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

Why is Fault Current Calculation Important?

A short-circuit current calculation determines the amount of current that flows through an electrical system during an abnormal condition. These conditions can occur when conductors make unintended contact, causing an unimpeded surge of current. Such events pose significant risks and can lead to equipment damage, fires, and personal injury.

Accurate calculations are essential because they enable engineers to size protection devices, such as circuit breakers, fuses, and relays—correctly. These devices must be capable of interrupting the available prospective current to prevent failures and ensure compliance with safety standards such as the National Electrical Code (NEC). For example, NEC 110.24 mandates that the available short-circuit current at service entrance equipment be labeled. This requirement ensures safe operation and proper protection.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Applying results from fault studies directly impacts the selection of circuit breaker types to ensure devices can safely interrupt maximum available current.

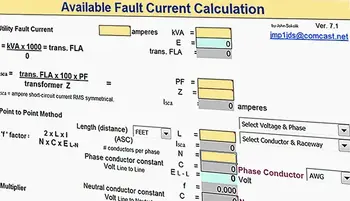

How is Fault Current Calculated?

Fault current calculation involves determining the short-circuit level at various points in the system. This requires knowledge of full-load current, the impedance of conductors, transformers, and other components. Engineers use mathematical formulas or specialized software to perform these studies.

Accurate values also influence the proper rating and application of fuse types, which protect conductors from excessive thermal and mechanical stress.

Basic Fault Current Calculation Principles

At the simplest level, short-circuit current can be understood using Ohm’s Law:

I = V ÷ R

Here, system voltage (V) is divided by circuit resistance (R). While this illustrates the concept, real-world systems also include reactance, making total impedance the governing factor.

Three-Phase Fault Current Calculation Formula

For practical applications, engineers often use a transformer-based calculation:

Fault Current (A) = (kVA × 1000) ÷ (√3 × Voltage) ÷ (%Z ÷ 100)

This formula estimates the prospective short-circuit current at a transformer’s secondary, based on its kVA rating, operating voltage, and impedance. It provides a more accurate reflection of the levels protective devices must handle.

Symmetrical vs. Asymmetrical Fault Currents

-

Symmetrical current is the steady-state sinusoidal current after the DC offset decays.

-

Asymmetrical current includes the initial DC offset, resulting in higher peak currents during the first few cycles.

This distinction is critical for selecting a protective device, as equipment must withstand and interrupt not only the steady-state current but also the higher asymmetrical peak.

Types of Faults

Faults differ in severity and current magnitude depending on how conductors and ground are involved:

-

Line-to-Ground – The most common, involving a single phase conductor and ground.

-

Line-to-Line – Two conductors come into contact, producing larger currents than single line-to-ground.

-

Double Line-to-Ground – Two conductors contact ground simultaneously.

-

Three-Phase – The most severe, creating the highest short-circuit current levels.

Advanced systems may require specialized protective relays or relay and circuit breaker coordination to manage fault conditions effectively.

Broader Benefits of Short Circuit Studies

Short-circuit studies are not limited to device sizing—they provide additional benefits:

-

Voltage depression analysis to protect sensitive loads.

-

Mechanical stress evaluation for conductors and busbars.

-

System reliability assurance by identifying and mitigating weak points.

-

Equipment design and maintenance planning to match ratings with real-world conditions.

Knowledge of fault current also supports transformer protection, ensuring that insulation and windings remain within safe thermal and mechanical limits.

Software Tools and Standards

Today, current analysis is supported by advanced software, which allows engineers to model complex systems, calculate available short-circuit currents, and coordinate protection devices efficiently.

Guidance is also available from global standards, including:

-

IEEE 1584 – Arc flash and current analysis

-

IEC 60909 – International short-circuit calculation standard

-

NFPA 70E – Electrical safety and compliance requirements

Adhering to these standards ensures accuracy, consistency, and compliance in system design and protection.

Frequently Asked Questions

What factors influence short-circuit current magnitude?

System voltage, component impedance, distance from the source, and the type of electrical disturbance all affect current levels. Lower impedance and higher voltage create larger currents, while events closer to the source are more severe.

What is the difference between symmetrical and asymmetrical fault currents?

A symmetrical current is the steady-state sinusoidal value after stabilization, while an asymmetrical current includes a DC offset in the first few cycles, creating higher peaks. Devices must be rated for both conditions.

How does fault current affect protective device selection?

Protective devices like breakers and fuses are chosen based on their interrupting capacity. If the available current exceeds that rating, catastrophic failure can occur. Accurate calculation ensures proper coordination and compliance with NEC and IEEE standards.

Related Articles