Arc Flash Study

Arc flash study helps identify electrical hazards, calculate incident energy, and define PPE requirements. This safety analysis is essential for compliance with NFPA 70E and OSHA standards, functioning as a complete electrical hazard assessment that protects workers and reduces arc flash risks in industrial and commercial settings.

What is an Arc Flash Study?

An arc flash study is a detailed evaluation of a facility’s electrical system to assess potential arc flash hazards.

✅ Identifies shock and arc flash risk levels

✅ Determines safe approach boundaries and PPE

✅ Ensures NFPA 70E and OSHA compliance

An arc flash study is essential for ensuring workplace electrical safety and minimizing the risk of serious injury. It combines multiple layers of assessment to identify potential hazards, calculate incident energy levels, and establish the appropriate protective boundaries and personal protective equipment (PPE) requirements.

Request a Free Training Quotation

To perform a complete assessment, you must first conduct an in-depth short circuit analysis, which includes identifying fault current, arc duration, and working distance. This forms the basis for calculating the incident energy — the thermal energy released during an arc fault — which is crucial for evaluating the risk level and selecting the appropriate level of arc-rated personal protective equipment (PPE).

To perform an electrical risk evaluation that meets compliance standards and protects workers, organizations must follow a structured approach grounded in IEEE 1584-2018. This methodology provides the framework for accurate calculations based on factors such as fault current, working distance, and arc duration. As part of a thorough electrical risk assessment, facilities must evaluate all electrical equipment to determine potential exposure to hazardous energy. One of the key outcomes of this process is identifying the level of arc flash PPE required for each task, ensuring workers are equipped with the proper personal protective equipment (PPE) based on actual incident energy levels. Beyond calculations, compliance involves meeting strict NFPA 70E label requirements.

A full assessment not only enhances worker safety, it also fulfills your legal and regulatory responsibilities under standards like NFPA 70E and CSA Z462. Facilities that proactively manage electrical hazards reduce the risk of downtime, injury, fines, and insurance complications. By investing in this evaluation, you are taking measurable steps to reduce risk and ensure compliance.

Key Components of an Arc Flash Study

-

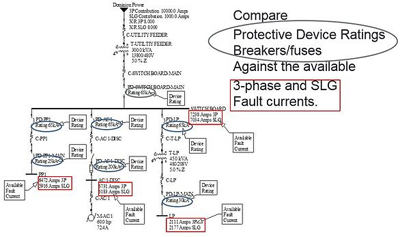

Short Circuit Study for Electrical Hazard Assessment

This step determines available fault current and ensures that all protective devices are properly rated. Fault current levels are a foundation for both incident energy analysis and labelling requirements.A short circuit study also identifies system weaknesses that could trigger excessive fault conditions, helping engineers properly size and coordinate breakers and fuses. This enhances system reliability and reduces the impact of outages when faults occur.

-

Protective Device Coordination Study

This study ensures that fuses, breakers, and relays operate in a sequence that limits arc energy and reduces equipment damage and personnel exposure.Proper coordination not only minimizes electrical hazard exposure but also prevents nuisance tripping and partial blackouts. This is especially crucial in critical environments, such as hospitals, data centers, and manufacturing facilities, where operational continuity is of paramount importance. Proper coordination is a critical part of any NFPA 70E compliance study, ensuring that safety devices work together to reduce exposure to dangerous fault currents.

-

Arc Flash Risk Assessment

The arc flash risk assessment evaluates the probability of an arc event occurring at each point in the system. The assessment process includes detailed incident energy calculations to determine the level of arc-rated PPE required for each task. It identifies tasks that require mitigation steps and establishes safety protocols that align with NFPA 70E and CSA Z462 standards.This process extends beyond raw data — it also involves evaluating human factors, maintenance practices, and the condition of equipment. By considering real-world conditions, the assessment helps you prioritize risk mitigation where it’s needed most.

-

Arc Flash Hazard Evaluation and Incident Energy Calculation

The arc flash hazard evaluation involves calculating incident energy at various locations and establishing boundaries. This determines safe working distances and the level of PPE required.It’s during this phase that labelling requirements are established, and decisions are made about barriers, remote switching, and alternative work methods. This ensures your team is equipped with actionable data, not just technical jargon.

-

Equipment Labelling, PPE Boundaries, and Documentation

Based on your findings, you will apply labels to the affected equipment. These labels must display boundary distances, fault current, incident energy, and required PPE. Labels must clearly define PPE boundaries so workers can maintain safe approach distances and comply with OSHA electrical safety standards. For more information on requirements, see our Arc Flash Study Requirements Guide.Accurate labelling ensures workers instantly understand the hazards present and how to protect themselves. Labels must be durable, legible, and consistently formatted across your facility to ensure maximum clarity and compliance.

Arc Flash Study Deliverables, Timeline, and Cost Overview

| Item | What’s Included | Typical Timeline | Cost Range* |

|---|---|---|---|

| Single-Line Electrical Model | Updated diagram of your facility’s electrical distribution system | 1–2 weeks (data collection & drafting) | Included |

| Incident Energy Calculation Table | Detailed results for each piece of equipment, in cal/cm² | 1 week after data collection | Included |

| Breaker/Fuse Setting Review | Study and adjustment recommendations for protective devices | Integrated into study | Included |

| Arc Flash Labels | Printed and/or digital labels for all applicable equipment | Upon final approval | Included |

| Mitigation Recommendations | List of practical steps to reduce incident energy levels | Included in final report | Included |

| Training & Review Session | Walkthrough of results and compliance guidance for your team | 1–2 hours, scheduled after delivery | Optional, quoted separately |

| Full Project | All items above | 2–4 weeks total | $X,XXX – $XX,XXX |

Note: *Cost range varies depending on facility size, equipment quantity, and complexity.

Related Compliance Standards

An arc flash study often forms part of a broader NFPA 70E compliance study, which may also include electrical hazard assessment, PPE boundary mapping, and OSHA electrical safety procedures. These elements work together to create a safer work environment and meet regulatory requirements.

Frequently Asked Questions

How often should an arc flash study be updated?

NFPA 70E recommends updating your electrical hazard assessment every five years, or sooner if there are significant changes to your electrical system, such as new equipment, altered protective device settings, or facility expansions. Calculations should follow the IEEE 1584-2018 standard to ensure accurate results based on fault current, working distance, and system configuration.

How much does it cost?

Costs typically range from $X,XXX to $XX,XXX depending on facility size, complexity, and number of electrical assets. A detailed quotation is provided after reviewing your system layout and requirements.

How long does it take to complete?

Most projects take 2–4 weeks from the initial site data collection to delivery of the final report, labels, and recommendations. Larger facilities may require additional time.

Who is responsible for preparing the site for the study?

The facility owner or manager is responsible for ensuring safe access to all electrical equipment, providing accurate single-line diagrams (if available), and coordinating with maintenance staff to support data collection.

What standards are used to perform the study?

Arc flash studies are typically performed in accordance with IEEE 1584 for incident energy calculations, NFPA 70E or CSA Z462 for safety compliance, and applicable OSHA regulations.

What deliverables are included?

Deliverables typically include an updated single-line diagram, incident energy calculation tables, breaker/fuse setting review, arc flash labels, and a list of recommended mitigation measures.

How does it improve safety?

By identifying hazard levels and proper PPE requirements, an NFPA 70E compliance study helps reduce the risk of injury, ensures compliance with safety standards, and improves overall electrical system reliability.

Don't Forget Training

Even the best report is useless without qualified workers. Proper training ensures that your staff understands the results of your incident energy evaluation and how to respond. Our arc flash study training course prepares your team to interpret assessment data, apply labels, and use PPE effectively.

Training also reinforces a culture of safety. When workers understand the “why” behind PPE, labelling, and procedures, they’re more likely to comply and make safer decisions on the job. Ongoing education supports long-term risk reduction.

Take the Next Step

If you're ready to build or update your arc flash study, our resources can help:

-

Start with our incident energy analysis guide.

-

Review how to set safe distances in our arc flash boundary overview.

-

Learn how OSHA requirements apply on our OSHA Electrical Safety page.

Or get in touch to request a group training quotation tailored to your facility.

An arc flash study is more than just a compliance task—it’s a proactive measure that saves lives and protects infrastructure. The Electricity Forum is here to help you stay safe, informed, and fully prepared.

Explore More Arc Flash Topics:

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.

On-Site Training

Interested in cost effective, professional on-site electrical training?

We can present an Electrical Training Course to your electrical engineering and maintenance staff, on your premises, tailored to your specific equipment and requirements. Click on the link below to request a Free quotation.

EF PARTNER MEDIA

Product Showcases

Shared Media