Arc Flash Risk Assessment for Reducing Risk

Arc flash risk assessment identifies electrical hazards, performs incident energy evaluation, and defines PPE boundary distances to ensure worker safety, NFPA 70E compliance, and effective PPE selection, preventing injuries in industrial and commercial electrical systems.

What is an Arc Flash Risk Assessment?

Arc flash risk assessment is a critical process used to identify electrical hazards, evaluate incident energy levels, and establish safe working boundaries.

✅ Determines incident energy levels and required PPE for worker protection

✅ Defines arc flash boundaries for safe working distances

✅ Ensures compliance with NFPA 70E and OSHA standards

By analyzing fault current, arc duration, and equipment conditions, facilities can reduce exposure to high-energy events and ensure compliance with NFPA 70E and OSHA regulations. This essential safety practice supports hazard mitigation, PPE selection, and overall electrical risk management.

Request a Free Training Quotation

What Is Involved in an Arc Flash Risk Assessment?

The arc flash risk assessment process is a comprehensive approach to identifying, analyzing, and mitigating electrical hazard exposure levels. It’s more than a safety audit—it’s a technical study that quantifies risks and recommends solutions.

Key steps include:

-

Data Collection

-

Review system one-line diagrams and gather electrical nameplate information.

-

Perform field verification to confirm the accuracy of drawings and component ratings.

-

Collect details on grounding, transformer configuration, and conductor lengths.

-

-

Short Circuit and Coordination Study

-

Conduct a short circuit analysis to identify the available fault current at each node.

-

Evaluate time-current coordination to ensure upstream devices operate before downstream ones.

-

-

Incident Energy Analysis

-

Use IEEE 1584 formulas to calculate incident energy release at various equipment points.

-

Factor in working distance, equipment enclosure type, and arc duration to determine exposure values.

-

-

Hazard Identification and Boundary Setting

-

Establish shock protection boundaries and arc flash boundaries based on calculated energy levels.

-

Define the approach limits and restricted zones for qualified personnel.

-

PPE Selection Based on Risk Levels

Once the energy levels are determined, proper Personal Protective Equipment (PPE) must be selected. This ensures that workers are protected based on the severity of the arc flash risk, expressed in calories per square centimetre (cal/cm²).

PPE categories are defined as follows:

-

Category 1 (up to 4 cal/cm²) – FR shirt and pants, face shield with balaclava

-

Category 2 (4.1–8 cal/cm²) – Category 1 PPE plus arc-rated coveralls or suit

-

Category 3 (8.1–25 cal/cm²) – Additional arc-rated layers, gloves, hard hat with hood

-

Category 4 (25.1–40+ cal/cm²) – Heavy-duty arc suit with flash hood, balaclava, and gloves

To explore further, review the arc flash study requirements for NFPA 70E compliance details.

Standards That Govern Arc Flash Risk Assessment

Arc flash hazard evaluations must adhere to established codes and methodologies. The two most recognized standards—NFPA 70E and IEEE 1584—guide risk identification, calculation, and control measures. To complete your understanding, explore the full risk modelling approach discussed in our arc flash hazard analysis article.

Compliance considerations include:

-

NFPA 70E – Defines safe work practices, PPE requirements, labelling protocols, and training expectations.

-

IEEE 1584 – Provides mathematical models for incident energy analysis based on real-world test data.

-

OSHA 29 CFR 1910.333 and 1910.269 – Mandate electrical hazard awareness and control as part of a broader safety program.

If you're concerned about your site's compliance with national regulations, see our guide to incident energy as a core element of electrical risk evaluation.

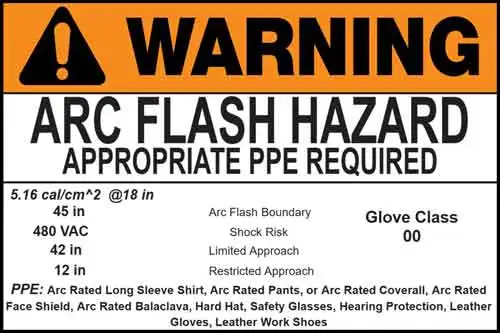

Labelling and System Documentation

Arc flash studies culminate in updated equipment labels, hazard documentation, and maintenance schedules. Labelling ensures that every worker understands the energy risk and PPE required before starting any energized task.

Required documentation includes:

-

Equipment-specific arc flash labels indicating voltage, incident energy, boundaries, and required PPE.

-

A formal engineering report detailing methods, assumptions, and recommendations.

-

A reassessment schedule, typically every five years or after major system modifications.

Explore how these elements are calculated in our incident energy analysis page, which outlines key factors that affect energy release.

Worker Safety Training and Risk Awareness

Arc flash awareness doesn’t stop at engineering—it must be reinforced through electrical safety training. Workers must understand the nature of the hazard and how to respond effectively in high-risk environments.

Training programs should cover:

-

How to read and interpret arc flash labels

-

Correct PPE usage based on hazard category

-

Steps for energized and de-energized work protocols

-

Lockout/tagout procedures and emergency response

For instruction on implementing a compliant and practical program, visit our arc flash analysis training page.

Summary and Takeaways

An Arc flash risk assessment is foundational to modern electrical safety programs. When properly executed, they:

-

Identify areas of high arc energy concentration

-

Reduce exposure through system and procedural changes

-

Improve compliance with OSHA and NFPA guidelines

-

Provide data-driven PPE and labelling requirements

-

Educate workers on how to respond to electrical hazard events

Related Articles:

On-Site Training

Interested in cost effective, professional on-site electrical training?

We can present an Electrical Training Course to your electrical engineering and maintenance staff, on your premises, tailored to your specific equipment and requirements. Click on the link below to request a Free quotation.

EF PARTNER MEDIA

Product Showcases

Shared Media