Electrical Protection

How to Test a Solid State Relay?

Use a multimeter to test a solid-state relay by checking the input voltage, output continuity, and switching function. Ensure the relay switches properly when the control voltage is applied across the input terminals.

How to Test a Solid State Relay?

Testing a solid state relay ensures proper operation and safe electrical system performance.

✅ Use a multimeter to check input and output terminals for voltage and continuity

✅ Apply control voltage to confirm switching functionality

✅ Verify load connection and output behavior under various conditions

Basic Protection Relay Training

Request a Free Training Quotation

Regular testing of solid state relays plays a vital role in ensuring the smooth operation and reliability of control systems. By implementing a combination of off-line and on-line testing procedures, users can proactively identify potential issues with SSRs and prevent costly downtime. Understanding the appropriate testing methods and safety precautions is crucial for maintaining optimal performance and ensuring the safe operation of SSRs within various applications. To ensure accurate testing of solid-state relays and other electrical components, it's essential to understand how to Use a Digital Multimeter, including its voltage, resistance, and continuity settings.

Preparing for Testing

Solid state relays (SSRs) are reliable and durable switching devices, but like all electrical components, they can degrade over time due to thermal stress, overvoltage, or excessive load conditions. Routine testing is essential to ensure these devices continue to operate within their design parameters. Whether used in industrial automation, HVAC systems, or power distribution, a malfunctioning SSR can compromise the performance and safety of the entire system. By implementing a structured testing routine, operators can identify potential issues early, verify the proper functioning of relays, and avoid costly unplanned outages. If you're new to SSRs or want to deepen your understanding of switching devices, start by reviewing the basics of What is an Electrical Relay is and how it differs from solid-state technology.

Required Tools and Equipment

To examine an SSR effectively, you will need:

-

A multimeter with continuity, diode, and resistance measurement functions

-

A controlled DC or AC power source for input signal simulation

-

A known load (e.g., resistive lamp or heater) for output switching validation

-

An oscilloscope for observing switching timing (optional but ideal)

-

A clamp meter or ammeter for current measurement

Importance of SSR Testing

Solid state relays are critical components in many industrial and commercial control systems, offering silent, fast, and reliable switching. However, their solid-state nature means internal failures may not be immediately visible or audible, making regular testing essential. Without proactive testing, a faulty SSR could remain undetected until it causes a system malfunction or downtime. Understanding why SSR testing matters—and how it contributes to system reliability, efficiency, and troubleshooting accuracy—helps maintenance teams prioritize it as part of a standard preventive maintenance routine. Protecting control systems requires proper circuit design, including the integration of an Overcurrent Protective Device to prevent equipment damage from excessive current flow.

Regular testing of SSRs is essential for several reasons:

-

Preventative Maintenance: Early detection of potential issues within an SSR can help prevent unexpected equipment failures and costly downtime.

-

Performance Verification: Testing ensures that SSRs continue to meet their specified switching speeds, load handling capabilities, and control signal requirements.

-

Troubleshooting: In case of equipment malfunctions within a control system, testing SSRs helps isolate the root cause of the issue.

There are two primary approaches to testing SSRs:

-

Off-Line: This method involves removing the SSR from the control system for a more comprehensive evaluation.

-

Online: This approach enables testing the SSR while it remains installed within the system, thereby minimizing downtime.

When troubleshooting malfunctioning circuits, it’s important to understand what is an Electrical Fault and recognize the various causes and consequences of electrical faults, which can stem from short circuits, ground faults, or overload conditions.

Off-Line Testing Methods

This offers a more controlled environment for evaluating SSR performance. Here are some common off-line testing procedures:

-

Visual Inspection: A basic yet crucial step involves visually inspecting the SSR for any signs of physical damage, such as burns, cracks, or discoloration on the housing. Additionally, checking for loose connections or corrosion on terminals is essential.

-

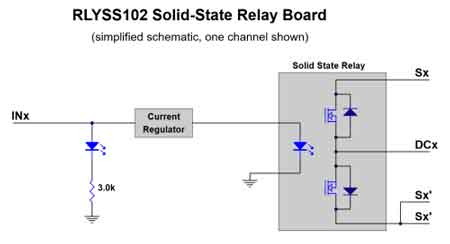

Input LED Diode: Using the multimeter’s diode mode, check the SSR’s input terminals. The forward voltage drop across the internal opto-isolator LED should fall within 1.0–1.5 V DC range. No reading could indicate a failed input circuit.

-

Control Signal Functionality: This inspection verifies the SSR's response to the control signal. A DC power supply can be used to provide a voltage within the specified control signal range. If the SSR is operational, applying the control signal should activate the output circuit as expected.

-

Load Current: With the SSR isolated from the actual load, a controllable current source can be used to simulate the load current. By gradually increasing the current and monitoring the voltage drop across the SSR, its ability to handle the intended load can be assessed. It's important to ensure the current doesn't exceed the SSR's rated capacity.

-

On-Resistance Measurement: With the SSR turned "on" under load, use a low-resistance meter to measure the output resistance. Values should be low (typically <1 Ω). Higher resistance may indicate internal contact wear or overheating.

-

Leakage Current Measurement: A sensitive multimeter can be used to measure the leakage current between the input and output circuits of the SSR when it's in the off state. Excessive leakage current can indicate internal degradation within the SSR and may necessitate replacement.

-

On-Resistance Measurement: The on-resistance of the SSR represents the resistance offered by the switching element when it's conducting. A low-resistance meter can be used to measure this value. The measured on-resistance should be within the manufacturer's specifications for the specific SSR model. An increase in on-resistance can indicate potential wear and tear within the switching element.

On-Line Testing Methods

This allows for a quick assessment of SSR functionality without system downtime. However, these methods may not be as comprehensive as off-line examination. Here are some common online approaches:

-

Control Signal Verification: Similar to the off-line method, a voltage meter can be used to measure the control signal voltage at the SSR's input terminals while the control system is operational. This verifies that the SSR is receiving the appropriate control signal.

-

Output Voltage Monitoring: For AC SSRs, a voltmeter can be used to measure the voltage across the load while the SSR is activated. A similar approach can be used with DC SSRs. In both cases, the measured voltage should be close to the supply voltage, indicating proper conduction through the SSR.

-

Functional Load Testing: Use a live load (e.g., incandescent lamp) to verify that the SSR properly completes the circuit when control voltage is applied. Absence of load can lead to misleading results, as some SSRs won’t switch visibly without it.

-

Pulse and Switching Delay Observation (Advanced): An oscilloscope can help measure switching response time and verify zero-cross behavior (if applicable). This is especially useful for high-speed applications and timing-sensitive circuits.

-

Temperature Monitoring: Using a non-contact temperature sensor, the SSR's housing temperature can be monitored during operation. An abnormal rise in temperature can be a sign of internal issues within the SSR and may warrant further investigation or replacement.

-

System Performance Observation: Carefully observing the overall performance of the control system can provide clues about potential SSR malfunctions. Signs like flickering lights, erratic motor behavior, or unexpected equipment shutdowns may indicate issues with the SSRs controlling those functions.

Safety Considerations During Testing

Safety is paramount when testing SSRs, especially when dealing with high voltages or currents. Ensure all equipment is properly grounded and follow standard electrical safety procedures to prevent accidents.

Safety is paramount when testing SSRs, especially during off-line testing procedures. Here are some crucial safety practices to follow:

-

Always refer to the manufacturer's datasheet for specific testing instructions and safety precautions.

-

Ensure the power supply is disconnected and all capacitors are discharged before handling the SSR.

-

Use appropriate personal protective equipment (PPE) such as safety glasses and gloves when working with electrical components.

-

Never exceed the SSR's rated voltage, current, or power handling capabilities during testing.

-

Be mindful of potential hot surfaces during on-line testing, especially when using temperature sensors

-

If any discrepancies are identified during testing, further investigation or replacement of the SSR may be necessary. It's important to consult the manufacturer's recommendations for troubleshooting and replacement procedures.

Maintaining Optimal Performance with SSR Testing

Regular testing of solid state relays plays a vital role in ensuring the smooth operation and reliability of control systems. By implementing a combination of off-line and on-line testing procedures, users can proactively identify potential issues with SSRs and prevent costly downtime. Understanding the appropriate testing methods and safety precautions is crucial for maintaining optimal performance and ensuring the safe operation of SSRs within various applications.

Related Articles

Download Our FREE Electrical Protection Handbook

Electrical System Protection And Control Handbook Vol. 3

This 100+ page technical handbook features valuable information for electric power engineers, consultants and others involved in the selection and coordination of overcurrent protective devices used in industrial, commercial and institutional power systems

The Electrical System Protection and Control Handbook, Vol. 3 is a comprehensive guide designed for electrical engineers, technicians, and professionals involved in the design, operation, and maintenance of power systems. This volume delves into the essential principles, technologies, and methodologies for protecting and controlling electrical systems, providing valuable insights into the latest advancements and best practices in the field.

In this edition, we explore a wide range of protection schemes, from traditional overcurrent and differential protection to more advanced techniques like distance and directional protection. We also examine the critical role of control systems, automation, and communication in ensuring that protective devices operate effectively and that faults are swiftly isolated to minimize disruption.

Volume 3 covers key topics such as coordination of protection devices, fault analysis, system stability, and the integration of modern digital protection relays. With the growing complexity of smart grids and renewable energy integration, this handbook also addresses the challenges and solutions associated with protecting and controlling these dynamic systems.

Latest Electrical Protection Articles

Fault Current Limiter Explained

A fault current limiter (FCL) is a protective device that reduces excessive fault currents in electrical systems. It enhances safety, protects equipment, and helps maintain system stability by limiting the peak current during short circuits or overload events.

Basic Protection Relay Training

Request a Free Training Quotation

What is a Fault Current Limiter?

✅ Reduces peak fault current to protect sensitive components and maintain system integrity.

✅ Improves coordination with overcurrent protection devices and circuit breakers.

✅ Works in conjunction with fault current calculation methods to effectively size protective equipment.

A Fault current limiter is a crucial device in modern electrical systems designed to manage and limit the dangerous surge of amperage during a fault or short circuit. By automatically reducing the current to safer levels, these devices protect critical equipment from damage and prevent system-wide outages. Commonly used in high-power and medium-voltage applications, fault current limiters provide enhanced protection by limiting the intensity of the fault current before it can impact transformers, circuit breakers, or other critical components. Their role is vital in improving overall system safety, efficiency, and reliability, making them an indispensable component in both industrial and utility power grids.

In modern electrical systems, fault current limiters serve as essential components for managing excessive amperage during abnormal conditions such as short circuits. These devices operate by limiting the current flowing through the system when faults occur, thereby preventing damage to equipment and ensuring system stability. This article explores the functionality of these devices, their various types, and the crucial role they play in system protection. A comprehensive overview of circuit protection devices helps explain the role of fault current limiters within the broader electrical protection strategy.

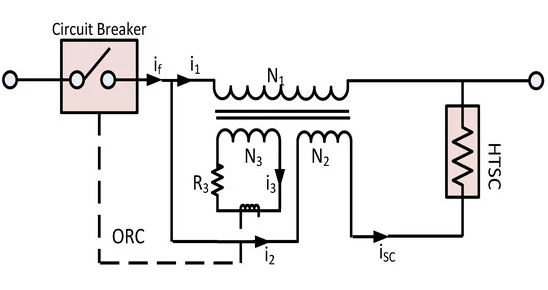

A fault current limiter (FCL) is an advanced protective device designed to automatically reduce excessive current in power systems during fault events. A key innovation in this field involves the use of high-temperature superconductors, which enable rapid response times and minimal energy loss. These superconducting fault current limiter technologies are particularly valuable in modern grids with distributed power sources, where traditional protection methods may fall short. By integrating SFCLs into electrical networks, utilities can enhance system stability, reduce equipment damage, and support the safe integration of renewable energy sources.

What Is a Fault Current Limiter, and How Does It Work?

A fault current limiter (FCL) reduces the intensity of amperage during a fault, allowing the system to handle abnormal conditions without overwhelming critical components. During a short circuit, currents can surge to hazardous levels, potentially leading to damage or system failure. The FCL prevents this by increasing impedance, which restricts current flow. By maintaining a lower current level during faults, the system avoids costly downtimes and equipment failures.

These devices work through a range of technologies, from passive elements like inductors to more advanced methods such as superconducting materials. Superconductors, for example, have very low resistance under normal conditions but react rapidly by increasing resistance during a fault.

Accurate fault current calculation is essential for selecting the proper protection devices, including fault current limiters, to ensure safe system operation.

Types of Fault Current Limiters

Several types of FCL are used, each designed for specific applications:

-

Superconducting: These devices utilize superconducting materials to respond rapidly during faults. They are especially beneficial in high-power systems due to their ability to handle larger loads.

-

Solid-State: These rely on power electronics to detect and limit abnormal amperage flows. They are fast and accurate, often used in medium-voltage systems where speed and precision are crucial.

-

Inductive: Inductive models are simpler but effective. They use inductors to limit current, increasing the system's impedance during a fault. These are frequently used in less demanding environments but still offer robust protection.

How Does a Fault Current Limiter Improve System Protection?

The primary function of a FCL is to protect electrical systems from damage caused by short circuits. By reducing fault currents to manageable levels, they prevent overheating and mechanical stress on components such as transformers and circuit breakers.

Without an FCL, short circuit conditions could result in dangerous spikes in amperage that overload protective devices. This would necessitate the installation of oversized equipment, increasing the cost and size of the system. By managing amperage levels, limiters make the system more efficient and cost-effective.

To understand how current limiting fuses function in coordination with fault current limiters, visit the page on current limiting fuse technology and applications.

Where Are Fault Current Limiters Typically Used?

These devices are used in several key applications:

-

Industrial power systems: FCLs ensure that high-demand industrial systems remain protected during faults, preventing downtime and safeguarding equipment.

-

Utility grids: Power transmission and distribution networks often rely on limiters to shield transformers and other infrastructure from excessive currents. Transformer protection systems also benefit from fault current limiting devices, especially in high-fault-current environments common in industrial power systems.

-

Renewable energy installations, such as wind farms and solar power plants, benefit from these devices, especially in medium-voltage applications, where variability in supply can increase fault risks.

What Are the Benefits of Using a FCL Compared to Other Protective Devices?

Compared to traditional protective devices like circuit breakers or fuses, limiters offer several distinct advantages:

-

Enhanced protection: An FCL responds faster than fuses or breakers, preventing the fault amperage from reaching dangerous levels and protecting sensitive equipment.

-

Reduced downtime: By limiting the fault, systems can continue operating even during abnormal conditions, reducing the need for system shutdowns.

-

Cost-effectiveness: Utilizing an FCL reduces the need for oversized equipment, resulting in savings on both installation and operational costs.

-

Improved safety: Limiting abnormal amperage flow reduces the risk of fires or explosions in high-power environments, especially during short-circuit events.

A FCL is critical to ensuring the safe and efficient operation of electrical systems. Their ability to control and limit dangerous amperage during faults makes them indispensable in high-power and medium-voltage environments. By understanding the types of limiters available and their role in protecting infrastructure, electrical engineers can ensure reliable and safe operations. Whether applied in industrial power systems, utility grids, or renewable energy plants, these devices play a vital role in maintaining system stability and protecting valuable equipment.

Related Articles

What Is Overcurrent Protection

What is Overcurrent Protection?

An overcurrent situation is either an overload or a fault/short-circuit. The overload current is an excessive current flow relative to normal operating current, but still confined to the normal branch circuit paths provided by the conductors and equipmen. A fault (often referred to as a short-circuit) flows outside the normal circuit paths.

The National Electrical Code defines overload and overcurrent as any current in excess of the rated current of equipment or the ampacity of a conductor. It may result from overload, short circuit, or ground fault.

It can be accomplished using overcurrent protection devices, such as fuses, circuit breakers or protective relays, which are designed to safety - they protect electrical equipment. Relay protection against overcurrent is one of the best electrical protection methods. From the graded overcurrent relay protection system, a discriminative short circuit protection can be achieved. Overcurrent relay protection should not be confused with ‘overload’ relay protection, which typically utilizes relays in a time related way to determine the thermal capacity of the equipment and cause a breaker to trip in order to protect the equipment from overload. Overcurrent relay protection is completely directed to the clearance of short circuits.

Power System Protection Courses

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

When it comes to fuses, there are several factors to consider:

- voltage rating

- rating of the fuse

- interrupting capacity

Overloads

Overload conditions are most often up to 6 times the normal current level. They are usually caused by harmless, temporary in-rush currents that occur when motors start up or transformers are energized. Such overloads, or transients, are normal occurrences, and their brief duration is not harmful to circuit components as the associated temperature rise is minimal with no harmful affect. It’s important that overload protection devices are properly sized and have the appropriate operating characteristics so they do not react to these temporary overloads or cause “nuisance openings.”

Persistent, non-temporary overloads can result from defective motors (worn bearings) or when a full load is on a single circuit and must not be permitted to last long enough to damage electrical system components such as conductors. This damage may eventually lead to severe fault events if the overload is not interrupted.

Due to the overload’s inherent low magnitude nature, removing them within seconds or even minutes will generally prevent thermal damage.

Faults

Faults, also referred to as short-circuits, differ from overloads as they can be hundreds to thousands of times greater than the normal operating current. Fault current is a general term that’s used in this publication and includes ground fault, arcing fault and short-circuit currents. A high level short-circuit may be up to 30 kA or 200 kA, and must be interrupted as quickly as possible to minimize the damage that can include:

• High magnetic forces that warp and distort busbars and associated

bracing beyond repair

• Severe insulation damage

• Melting or vaporizing conductors

• Vaporizing metal, including buswork in electrical equipment

• Ionized gases

• Arcing fires

• Explosions

Friemel’s Law

Paul Friemel was known in the electrical industry as the Professor of Overcurrent Protection from the mid-1960s until his passing in 2015. As a licensed professional engineer, he presented seminars on electrical overcurrent protection for more than 40 years.

Friemel taught the three C’s of overcurrent protection which are now known as Friemel’s Laws of Overcurrent Protection:

1. Interrupting rating (Capacity)

2. Component Protection

3. Selective Coordination

An understanding of these three key electrical overcurrent protection principles will lead to a safe, reliable and code compliant electrical system.

Read Other Electrical System Protection Articles

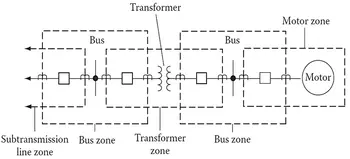

Transformer Protection Explained

Maximum Fault Current Calculation

Transformer Cutout Fuse Explained

A transformer cutout fuse is a critical component in electrical distribution systems, providing essential protection against overcurrent conditions and preventing damage to transformers and other equipment.

What is "transformer cutout fuse"?

A transformer cutout fuse is a protective device mounted on power poles to safeguard distribution transformers.

✅ Interrupts power during short circuits or overload conditions

✅ Allows linemen to isolate and safely service transformers

✅ Prevents transformer damage and enhances grid reliability

This device acts as a safeguard by disconnecting the transformer from the system in the event of a fault or surge, ensuring the safety and reliability of power supply networks. Distribution transformers is important in delivering electricity from the power grid to end users, especially in overhead distribution systems commonly seen in suburban and rural areas.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

To ensure safety and protect equipment from faults, these systems often rely on a power fuse, which acts as a first line of defence against overcurrent conditions. One widely used design in such applications is the Type XS overcurrent protector, known for its reliability and compatibility with standard transformer cutout mounts, providing consistent performance in a variety of field conditions. Whether used in residential, commercial, or industrial settings, the transformer cutout overcurrent protector plays a vital role in minimizing the impact of electrical faults, reducing downtime, and protecting valuable infrastructure from catastrophic failures. Understanding the operation and maintenance of a transformer cutout overcurrent protector is key to ensuring long-term system efficiency and safety. For a comprehensive discussion on the different Types of Fuses and Overcurrent Protection Devices in electrical systems, you can check the dedicated page on overcurrent protection technologies.

A pole-mounted fuse is a critical component of distribution protection systems in overhead electrical networks, designed to safeguard transformers and other equipment from overload conditions. At the heart of this setup is the fuse link, a replaceable element that melts when excessive current flows through, thereby breaking the circuit and preventing further damage. One common type used in these applications is the expulsion fuse, which extinguishes the arc by releasing gases generated from the fuse element itself. The fuse holder secures the fuse in place, allowing for easy inspection and replacement. Together, these components ensure effective fault current interruption, minimizing downtime and enhancing electrical safety in utility environments.

Types of Transformer Cutout Fuses

Transformer cutout fuses are available in two primary types: expulsion fuses and current-limiting fuses.

-

Expulsion fuses are widely used in overhead distribution systems. They interrupt overcurrents by creating an arc inside a tube, which is then extinguished by gases expelled from the burning fuse link material.

-

Current-limiting fuses, on the other hand, are designed to respond quickly to high fault currents. They limit the peak let-through current by opening the circuit before the fault reaches its maximum level. This makes them suitable for installations where rapid fault current interruption is required to protect sensitive equipment. Choosing the right fuse type depends on system voltage, fault current levels, and coordination with upstream and downstream devices.

How to Choose the Right Fuse Rating

Selecting the correct fuse rating is essential for reliable operation and transformer protection. The rating should be based on the transformer's full-load current, inrush characteristics, and the maximum short-circuit current at the point of installation. Underrated fuses may cause nuisance trips, while overrated fuses could fail to interrupt dangerous fault currents. Consult the manufacturer’s coordination tables and distribution protection guidelines to determine the optimal balance between protection sensitivity and equipment tolerance. Factors like kVA rating, system voltage, and the fuse link speed class (e.g., slow-blow vs. fast-acting) all play a role in proper selection.

Installation and Safety Tips

Proper installation of pole-mounted fuses is critical for system reliability and lineman safety.

-

Always de-energize the circuit before installation.

-

Use insulated tools and personal protective equipment (PPE) that comply with local safety standards.

-

Ensure that the fuse holder is clean, securely mounted, and aligned with the cutout arm.

-

Check for visible signs of wear or corrosion, especially on contact surfaces.

-

When replacing a blown fuse, verify the cause of the fault before re-energizing the system.

Regular maintenance checks can prevent unplanned outages and extend the lifespan of the fuse assembly.

Common Failure Modes and Troubleshooting

Although transformer cutout fuses are robust, failures can occur due to improper sizing, environmental conditions, or mechanical wear. Common issues include:

-

Premature fuse link melting from misapplied ratings or transformer inrush

-

Mechanical fatigue in the hinge or fuse holder leads to poor connections

-

Contamination from dust or wildlife interfering with the operation

-

Corrosion in humid or coastal environments causes contact resistance

Troubleshooting should begin with a visual inspection and a review of the load conditions before the failure. Replace the fuse with one of the same rating and check for recurring problems that may indicate upstream issues or load imbalance.

Frequently Asked Questions

What Is the Purpose of a Transformer Cutout Fuse?

The primary function of an overcurrent protector cutout is to protect distribution lines from surges and overloads that can occur during faults. When excessive current flows through the system, the fuse element within the device melts, interrupting the electrical path and preventing further damage to connected equipment.

Installed on feeder lines, the cutout acts as the first line of defence against dangerous conditions. By disconnecting the fuse holder, the system isolates the affected section, preventing damage from spreading across the entire network. This selective disconnection ensures that only the faulty area is impacted, which helps maintain stability in the larger distribution system. Fuse Cutouts and Their Functionality are important to understand the flow of electricity well.

How Does a Transformer Cutout Fuse Work?

A fuse cutout operates through several key components, including the fuse tube, fuse link, and polymer insulator. When a fault occurs, the overcurrent protector link melts, interrupting the flow of current. This process prevents the electrical surge from damaging other critical elements in the system.

To safely remove the overcurrent protector holder for replacement, technicians often use a hot stick, allowing them to avoid direct contact with live electrical parts. Once the faulty overcurrent protector is removed, the system is ready for maintenance or inspection, preventing further risks from live components.

What Are the Typical Ratings?

The ratings for an overcurrent protector cutout depend on the specific application, including the current and voltage requirements of the system it protects. For example, cutouts typically range from 10 to 100 amps, with voltage ratings ranging from 5 kV to 35 kV. The correct rating ensures that the protection device responds appropriately to faults without disrupting normal system operations.

The ratings must align with the system's needs to ensure that it can handle both regular operations and fault conditions. Selecting the right overcurrent protector element is crucial for balancing the system's safety with operational efficiency.

When Should a Transformer Cutout Overcurrent Protector Be Replaced?

An overcurrent protector cutout requires replacement when the fuse element has melted due to an overcurrent condition. This indicates that the overcurrent protector has successfully protected the system, but a new one must be installed to restore protection. Routine inspections of the cutout and other components, such as the polymer insulator and upper contact, ensure that the system remains in good working order.

Maintenance should also include checking for signs of wear, corrosion, or damage to ensure reliable performance. Replacement is critical when any signs of degradation are detected.

What Are the Consequences of a Blown Transformer Cutout Overcurrent Protector?

A blown-overcurrent protector cutout leads to an interruption in power to the affected area of the distribution line. The cutout isolates the faulted section, allowing the rest of the system to function normally. However, power will remain disconnected in the impacted area until the overcurrent protector is replaced.

If the blown-overcurrent protector is not replaced promptly, it can lead to extended outages and potential operational issues. In some cases, a blown overcurrent protector can indicate an underlying fault, such as a transformer overload or short circuit, that needs further investigation before power can be safely restored.

The overcurrent protector cutout is an indispensable protection device in electrical systems, ensuring that feeder lines and distribution equipment are safeguarded from faults and surges. By understanding how this device works, when it needs to be replaced, and how it interacts with the larger electrical network, system operators can ensure reliable and safe operations.

Regular inspections, selecting the appropriate overcurrent protector rating, and promptly replacing blown overcurrent protectors are essential for ensuring that electrical systems remain efficient and safe. Proper management of these devices helps minimize downtime and protects both equipment and personnel from dangerous conditions.

For a more detailed explanation of transformer protection devices, visit our article on the role of transformer protection and short circuit protection in safeguarding electrical equipment.

Related Articles

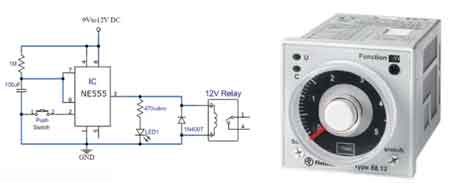

Time Delay Relay

A time delay relay controls the timing of electrical circuits by delaying switching operations. Commonly used in HVAC systems and motor control, it enhances safety, prevents equipment damage, and ensures proper sequencing of electrical processes.

What is a Time Delay Relay?

A time delay relay plays a crucial role in modern electrical and automation systems, providing precise control over when electrical circuits are activated or deactivated. It:

✅ Delays circuit activation or deactivation to control timing.

✅ Improves automation and motor start-up sequencing.

✅ Protects equipment by preventing sudden electrical surges.

Unlike standard relays that switch instantly upon receiving a signal, these devices introduce a controlled pause before engaging or disengaging a circuit. This functionality has become essential for various industrial, commercial, and residential applications, providing operational flexibility and safety enhancements. A time delay relay works alongside other protective devices, such as circuit breakers, to ensure reliable power system protection.

Basic Protection Relay Training

Request a Free Training Quotation

Types of Time Delay Relays

One of the most important aspects of understanding time delay relays is recognizing the different types available. Each type serves a distinct purpose, enabling tailored control of electrical systems. On-delay relays, for example, introduce a set period before activating a circuit once a signal is received. This type is often used in motor control applications where gradual power engagement is necessary. Off-delay relays, by contrast, maintain power to a circuit for a specified period after the signal is lost, commonly seen in lighting control systems that allow lights to remain on briefly after a switch is turned off. Interval timer relays offer an additional function by activating and deactivating circuits for specific intervals, making them particularly useful in repetitive operations, such as conveyor belt control. Multi-function protective devices combine these features into a single, versatile unit, providing users with multiple timing options in one device. Unlike a standard relay, a delay relay can be combined with multifunction relays to provide more advanced timing and coordination features.

Applications Across Industries

The applications of delay relays are extensive, spanning multiple industries. In industrial automation, they are essential for controlling sequential operations in machinery, ensuring that each step occurs in the correct order. For example, in motor start-up sequences, time delay relays enable staggered activation, preventing power surges that could damage equipment. In HVAC systems, these protective devices manage the precise timing of fan operations, damper movements, and system shutdowns to optimize energy efficiency. Lighting control systems also benefit from time delay functionality, enabling scheduled on-off cycles, emergency lighting activation, and dimming effects for improved energy management. Security systems utilize these relays to trigger alarms, control access points, and activate security cameras at the precise moment, ensuring a rapid and precise response to detected threats.

Selecting the Right Delay Relay

Selecting the right time delay relay for a particular application requires consideration of several key factors. The voltage rating is crucial, as the protective device must be compatible with the system’s operating voltage. The time range is another vital factor, as different applications require different delay durations. Whether the delay requires a few milliseconds or several minutes, selecting a protective device with the correct range is essential. Contact configuration also matters, as some applications require normally open (NO) contacts, while others need normally closed (NC) contacts. Additionally, the mounting style must be evaluated based on the physical space available for installation. Environmental conditions, such as temperature, humidity, and vibration, should also be considered to ensure the protective device's longevity and reliability in challenging conditions. Proper coordination between a relay and circuit breaker is essential when incorporating delay relays into automation or motor control systems.

Troubleshooting and Maintenance

Despite their reliability, time delay relays can experience operational issues. Troubleshooting these devices involves identifying and resolving common issues such as incorrect wiring, power supply interruptions, and component failures. One frequent issue is inaccurate timing, which may be caused by wear and tear or poor calibration. Visual inspection can reveal obvious faults, such as loose wires or signs of damage. Voltage measurements help verify power supply issues, while testing individual components can detect internal malfunctions. Calibration is also critical to ensure that timing settings are accurate, as improper calibration can lead to equipment malfunctions. Preventive maintenance is a proactive approach to avoid such issues. Regular cleaning, lubrication, and inspection of contacts can significantly extend the lifespan of the protective device, ensuring consistent performance. In high-demand environments, a delay relay may be paired with complex protective relays to sequence multiple operations safely and efficiently.

The Future of Delay Relays

The technology behind time delay relays continues to evolve. Traditionally, electromechanical devices dominated the market, but modern solid-state protective devices are now gaining popularity. Solid-state designs eliminate moving parts, reducing wear and increasing durability. These protective devices are also faster and more precise, making them ideal for applications that require high-speed switching. Another technological advancement is the use of microprocessor-based protective devices. Modern automation often uses delay relays in combination with solid state relays, which offer faster switching and greater reliability.

These devices incorporate advanced features, including programmable timing functions and communication capabilities. They enable operators to remotely customize delay settings, which is particularly useful in large-scale industrial automation systems. The rise of IoT (Internet of Things) integration has also influenced the design of time delay relays. By connecting protective devices to IoT networks, operators can remotely monitor and control them, providing access to real-time updates and predictive maintenance alerts. This connectivity is a game-changer for industries seeking to enhance operational efficiency.

Energy efficiency is another area where time delay relays are making an impact. Modern designs incorporate features that reduce power consumption during idle periods. This is especially beneficial in large-scale industrial facilities where energy costs are significant. By optimizing the use of protective devices, companies can reduce energy waste and enhance overall system efficiency. Additionally, eco-friendly designs are emerging, with manufacturers producing relays made from sustainable materials and employing production processes that have a lower environmental impact. Engineers designing motor or transformer protection systems often use delay relays with short circuit protection and overcurrent protection to prevent equipment damage.

Frequently Asked Questions

What is the purpose of the time delay?

The purpose of a time delay is to control the timing of electrical circuits and devices by delaying the activation or deactivation of connected equipment. Time delays are used to sequence events, prevent short cycling, avoid inrush currents, and ensure the safe operation of electrical systems. They are commonly applied in industrial control systems, motor protection, and lighting systems, among other applications.

What is the trigger on a time delay relay?

The trigger on a time delay relay is the event or signal that initiates the timing sequence of the device. This trigger can be a change in voltage, current, or the state of a control input (like a push button, limit switch, or control signal from a PLC). Once the trigger is activated, the protective device initiates its timing operation, which can either delay or accelerate the energizing or de-energizing of its output contacts, depending on the mode of operation.

What are the four modes of time delay relays?

The four main modes of time delay relays are:

-

On-Delay: It waits for a preset time after the trigger is activated before closing its output contacts. This mode is used to delay the start of devices, such as motors or lighting.

-

Off-Delay: It maintains its output contacts in the "on" position for a preset time after the trigger is deactivated. This is used for applications like keeping equipment running for a short period after power is removed (e.g., exhaust fans).

-

Interval On: This device immediately activates its output contacts when the trigger is activated, but only for a preset time, after which the contacts return to their original state. This is used for tasks like short-term activation of alarms or indicator lights.

-

One-Shot (Single Shot): The output contacts activate for a fixed time period when the trigger is applied, regardless of how long the trigger is held. This is used in applications where a single action or pulse is required, such as starting a machine repeat cycle or generating a pulse signal.

Related Pages

Relay and Circuit Breaker Coordination

Relay and circuit breaker coordination ensures selectivity and discrimination using time-current curves, protection settings, grading margins, and short-circuit analysis to optimize fault clearing, minimize arc flash energy, and improve power system protection reliability.

What Is Relay and Circuit Breaker Coordination?

A protection study aligning relays and breakers for selective fault clearing, minimal arc flash, and system reliability.

✅ Set time-current curves and pickup levels for selectivity

✅ Validate grading margins via short-circuit and coordination studies

✅ Limit arc flash and nuisance trips while meeting IEC/IEEE standards

Relay and circuit breaker coordination is the process of ensuring that the protective devices in an electrical power system work together effectively to isolate and clear faults with minimal disruption to the system. This coordination is essential to maintain the reliability, safety, and efficiency of the electrical network. For readers new to relay operation, the overview in how a relay functions clarifies sensing principles and typical trip logic.

In a power system, there are multiple protective devices such as relays, circuit breakers, fuses, and other protection schemes. When a fault occurs, these devices must operate in a coordinated manner to detect, isolate, and clear the fault. The main goals of coordination are:

- Selectivity: The protective devices should operate in such a way that only the faulty section of the system is isolated, leaving the rest of the system unaffected. This minimizes the impact on healthy parts of the network and reduces the risk of cascading failures.

- Speed: The protective devices should act quickly to clear faults, minimizing the potential for equipment damage and reducing the risk of injury to personnel.

- Sensitivity: The protective devices should be sensitive enough to detect and respond to even the smallest faults, ensuring that the system remains protected at all times.

- Reliability: The protective devices should be reliable and consistent in their operation, ensuring that the system remains protected in all conditions.

Among these devices, the role of protective relays is to interpret abnormal conditions and initiate isolation commands.

Coordination is achieved by setting the operating characteristics, such as current and time settings, of the protective relays and other devices in a way that ensures the most appropriate device operates first in response to a fault. This often involves using time-current curves, which represent the time it takes for a device to operate at different current levels. By adjusting the settings and comparing these curves, engineers can ensure that devices are coordinated correctly to provide optimal protection for the system. Time-current coordination is commonly implemented with an overcurrent relay whose curve can be graded with upstream and downstream devices.

If you want to own a robust commercial power system, then you must invest in a proper power distribution system design involves several steps. These steps include: examination of line diagrams, a short circuit analysis, coordination study, selective coordination and integration of overcurrent protective devices. It is incumbant on electrical engineers to understand power system protection relay settings. As part of that design, robust overcurrent protection ensures selective clearing while supporting equipment duty compliance.

What role does a circuit breaker play in electrical protection?

A CB plays a critical role in electrical protection by safeguarding electrical systems and equipment against overloads, short circuits, and other faults. For example, when a fault condition, such as an excessive current flow, occurs in an electrical circuit, the circuit breaker detects the abnormality. As a result, it automatically interrupts the current flow to prevent damage to electrical equipment and wiring and to reduce the risk of electrical fires or other hazards. For context on device construction and ratings, see what is a circuit breaker for definitions that align with code terminology.

Here are the primary roles a circuit breaker plays in electrical protection:

- Overload protection: CBs protect electrical circuits from overloads, which occur when too much current flows through a circuit due to an excessive load or demand. The circuit breaker prevents overheating and damage to the electrical system and connected devices by tripping and disconnecting the circuit.

- Short circuit protection: Short circuits happen when a live wire comes into contact with a neutral or ground wire, leading to a sudden surge in current. Circuit breakers detect this abnormal condition and quickly interrupt the flow of current, protecting electrical equipment and wiring from damage and minimizing the risk of electrical fires.

- Ground fault protection: Ground faults occur when there is a leakage of current to the ground due to damaged insulation or faulty wiring. Some circuit breakers, like Ground Fault Circuit Interrupters (GFCI), are specifically designed to detect ground faults and quickly disconnect the circuit to prevent electrical shocks and fires.

- Coordination and isolation: Multiple circuit breakers protect different levels in a power system. When a fault occurs, the coordination between circuit breakers ensures that only the affected portion of the system is isolated, minimizing disruptions and maintaining the overall system's stability.

How does a CB communicate with an electrical relay?

A CB communicates with an electrical relay through control circuits and communication protocols. Electrical relays, also known as protective relays, are devices that monitor specific parameters in the power system, such as voltage, current, and frequency. When the relay detects abnormal conditions or faults, it sends a trip signal to the CB to open the circuit, interrupts the current flow, and isolates the faulty section of the power system. If you need a primer on device types, this brief guide to what is a protective relay helps frame the communication path and tripping workflow.

Here's a brief overview of how a circuit breaker communicates with an electrical relay:

- Sensing and monitoring: The relay continuously monitors the electrical parameters of the system through current transformers (CTs), and voltage transformers (VTs) connected to the power lines. These transformers convert high-voltage and high-current signals into lower levels suitable for the relay's input.

- Fault detection: When the relay detects a fault or abnormal condition based on the pre-set thresholds and settings, it initiates a trip signal. These settings are typically adjustable and can be customized based on the system's requirements and coordination with other protective devices.

- Trip signal transmission: The trip signal is sent from the relay to the circuit breaker through control wiring, which connects the relay's output contacts to the circuit breaker's trip coil. In some modern power systems, digital communication protocols, such as IEC 61850, transmit trip signals and other information between relays and circuit breakers.

- Circuit breaker operation: Upon receiving the trip signal, the circuit breaker's trip coil is energized, activating the breaker's mechanical operating mechanism. This causes the circuit breaker box to open its contacts, interrupting the current flow and isolating the power system's faulty section.

- Reset and reclosing: After the fault has been cleared, the relay can also send a close signal to the CB, instructing it to close its contacts and restore power to the isolated section of the system. Some CBs have automatic reclosing functions, while others require manual intervention to reset and close the breaker.

What are the main challenges in achieving effective relay and circuit breaker coordination?

Achieving effective relay and circuit breaker coordination can be challenging due to several factors. Some of the main challenges include:

- System complexity: Modern power systems are increasingly complex, with numerous interconnected components, distributed generation sources, and changing load conditions. This complexity makes it more difficult to determine the appropriate settings for protective devices to ensure coordination.

- Varying fault conditions: Faults can occur in different locations, with varying magnitudes and types (such as short-circuits, ground faults, or overloads). Protective devices must be able to detect and respond to these diverse conditions while maintaining coordination.

- Infeed and outfeed effects: In large interconnected systems, the flow of fault current can be influenced by other connected devices or sources. These infeed and outfeed effects can complicate the coordination process and require careful consideration in the settings of protective devices.

- Selectivity vs. speed trade-off: Ideally, protective devices should operate quickly to minimize equipment damage and maintain system stability. However, faster operation can compromise selectivity, leading to unnecessary tripping of healthy sections of the network. Balancing selectivity and speed is a key challenge in coordination.

- Aging equipment and system changes: Over time, equipment may degrade or be replaced, and system configurations may change due to load growth, maintenance, or other factors. These changes can affect the coordination settings and may require periodic reviews and adjustments to maintain effective coordination.

- Multiple protection schemes: Modern power systems often employ multiple protection schemes and devices, including directional, distance, and differential relays. Coordinating these different protection schemes can be challenging and may require specialized expertise.

- Human factors: Proper coordination relies on accurate data, correct assumptions, and the expertise of the engineers responsible for setting up the protection system. Human error or miscommunication can lead to incorrect settings and compromised coordination.

Overcoming these challenges requires a thorough understanding of power system behavior, protective devices, and coordination principles. Engineers often use specialized software tools, time-current curves, and simulation techniques to analyze and optimize the coordination of relays and circuit breakers in power systems. In modern schemes, deploying multifunction relays can streamline coordination settings and reduce panel complexity.

Related Articles

Circuit Protection Devices Explained

Circuit protection devices safeguard electrical systems by interrupting overloads, short circuits, and faults. Essential in residential, commercial, and industrial applications, they enhance safety, improve reliability, and ensure compliance with electrical codes and standards.

What are Circuit Protection Devices?

Circuit protection devices are components designed to safeguard electrical systems and equipment from damage resulting from overloads, short circuits, and other electrical faults.

✅ Prevent equipment damage by interrupting excessive current

✅ Improve electrical safety in homes, industry, and utilities

✅ Ensure compliance with electrical codes and reliability standards

A strong foundation in what is electrical protection helps explain the principles that guide the design and use of all devices.

Basic Protection Relay Training

Request a Free Training Quotation

Perhaps the most serious electrical problem is a direct short. This occurs when a conductor at full system voltage comes into contact with ground or the return side of the path, creating a nearly resistance-free flow. The wires, which have limited capacity, can overheat rapidly. Left unchecked, this heat can cause conductors to melt or damage equipment. Protection devices, often working with overcurrent protection, interrupt the fault before it escalates.

In aircraft and other specialized systems, wires are usually small-gauge and sensitive to excessive current. That is why fuses, relays, and breakers are carefully coordinated to ensure faults are isolated quickly without causing further damage.

Other forms of protection include the residual current device, which detects leakage currents that may pose shock hazards, and solid-state solutions that provide fast and reliable switching. While circuit breakers and fuses handle larger systems, small devices such as thermal protectors and miniature breakers extend the same safety principles to individual appliances and sensitive electronics. Together, these devices form an essential safety network designed to protect both equipment and people from electrical hazards.

Protective Devices in Action

To protect electrical systems, several devices are installed: fuses, circuit breakers, thermal protectors, and arc fault interrupters.

These protective devices all share the same purpose — to safeguard wiring and connected equipment. Some are designed primarily to protect conductors, while others isolate specific components in the event of overheating. Basic Protective Relay Training provides professionals with the skills to apply and test these solutions effectively.

Other options include the residual current device, which detects leakage currents that may pose shock hazards, and solid-state technologies that deliver fast, reliable switching. While fuses and breakers cover large networks, small devices such as thermal protectors extend safety principles to appliances and sensitive electronics.

Fuse

Figure 1 shows the schematic symbol for the fuse. Fuses are used to protect the circuit from overcurrent conditions. The fuse is installed in the circuit so that all the current in the circuit passes through it. In most fuses, the strip of metal is made of an alloy of tin and bismuth, which will melt and open the circuit when the current exceeds the rated capacity of the fuse. For example, if a 5-amp fuse is placed into a circuit, the fuse will allow currents up to 5 amps to pass. Because the fuse is intended to protect the circuit, it is crucial that its capacity matches the circuit's needs.

When replacing a fuse, consult the manufacturer’s instructions to ensure a fuse of the correct type and capacity is installed. Fuses are installed in two types of fuse holders in aircraft. “Plug-in holders” or in-line holders are used for small and low-capacity fuses. “Clip” type holders are used for heavy, high-capacity fuses and current limiters.

Fig. 1 - Schematic symbol for fuse.

Current Limiter

Similar to a fuse, a current limiter uses a copper link that tolerates short-term overloads but opens under sustained excess current. They are often used to sectionalize high-current systems, such as aircraft buses. Once opened, they must be replaced.

Circuit Breaker

The circuit breaker is commonly used in place of a fuse and is designed to break the loop and stop the current flow when the current exceeds a predetermined value. Unlike the fuse, the breaker can be reset; whereas the fuse or current limiter must be replaced. Figure 10-67 shows the schematic symbol for a breaker. In many applications, transformer protection relies on fuses, relays, and breakers to safeguard expensive utility equipment from electrical damage.

Fig. 2 - Schematic symbol for breaker

There are several types of breakers commonly used in aircraft systems. One is a magnetic type. When excessive current flows in the circuit, it makes an electromagnet strong enough to move a small armature, which trips the breaker. Another type is the thermal overload switch or breaker. This consists of a bimetallic strip, which, when overheated by excessive current, bends away from a catch on the switch lever, permitting the switch to trip open.

Most circuit breakers must be reset by hand. If the overload condition still exists, the breaker will trip again to prevent damage to the circuit. At this point, it is usually not advisable to continue resetting the breaker; instead, initiate troubleshooting to determine the cause. Repeatedly resetting a breaker can lead to damage to the circuit or its components, which may then cause the breaker to trip again. Another type is the thermal overload switch or breaker. This consists of a bimetallic strip, which, when overheated by excessive current, bends away from a catch on the switch lever, permitting the switch to trip open.

An breaker can be reset after it trips, unlike a fuse, which must be replaced. This makes it one of the most common devices used to protect an electrical circuit from damage caused by overloads or faults. In large-scale power distribution systems, breakers safeguard high voltage circuits, while in homes, they are used to protect every household appliance from dangerous currents. Depending on the design, breakers can be reset manually or automatically, offering flexibility in how they respond to faults.

Arc Fault Circuit Breaker

In recent years, the arc fault breaker has begun to provide an additional layer of protection beyond that already provided by conventional breakers. The arc fault breaker monitors the circuit for an electrical arcing signature, which can indicate possible wiring faults and unsafe conditions. These conditions can lead to fires or loss of power to critical systems. The arc fault breaker is only beginning to make an appearance in the aircraft industry and is not yet widely used, unlike the thermal-type breaker. Modern arc fault interrupter breakers extend the role of circuit protection by detecting dangerous arcing conditions that traditional breakers may not identify.

Frequently Asked Questions

What are circuit protection devices?

Protection devices, such as fuses, circuit breakers, and relays, are components that prevent overloads, shorts, and faults to protect electrical systems.

Why are these devices important?

They prevent equipment damage, reduce fire hazards, improve system reliability, and ensure compliance with electrical safety codes.

What are common types of circuit protection devices?

The most common types include fuses, breakers, current limiters, thermal fuses, and arc fault circuit interrupters (AFCIs). Specialized applications, such as surge protection devices for elevators, demonstrate how circuit protection technology is tailored to safeguard both equipment and passengers.

How do they work?

They monitor current flow and interrupt the circuit when excessive current, faults, or unsafe conditions occur, protecting both wiring and connected equipment.

Related Pages