Power quality monitoring is a crucial process in electrical power engineering that can help ensure a stable power supply and prevent equipment failure and downtime.

With the help of power quality monitoring, power-related issues can be identified and rectified promptly, leading to improved performance and extended equipment life. Several types of equipment are used for power quality monitoring, including power quality analyzers, power quality meters, data loggers, and power quality monitoring systems. Regular monitoring is essential for maintaining the equipment's performance and extending its life by reducing the stress on the equipment due to poor power quality.

The frequency of monitoring can depend on several factors, such as the criticality of the equipment, the age of the equipment, the type of power supply, and the environmental conditions. Power quality monitoring can be performed by electrical engineers or trained personnel with the necessary knowledge and expertise in power systems. The role of power quality monitoring in data centers is crucial. High-speed data logging is a critical aspect of power quality monitoring that allows for the early detection of power-related issues and optimizing power usage.

What is Power Quality Monitoring, and Why is it Important?

Power quality monitoring is a process that aims to identify and rectify power-related issues that can cause equipment failure and downtime by monitoring and analyzing the electrical signals in a power system. It helps ensure that electrical power is supplied consistently and reliably without interruptions or disturbances. It is crucial in various industries, such as data centers, where downtime can result in substantial financial losses. Power quality monitoring also helps maintain equipment performance and extend its life by reducing the stress on the equipment due to poor power quality.

What Types of Equipment are Used for Power Quality Monitoring?

Several types of equipment are used for power quality monitoring, including power quality analyzers, power quality meters, data loggers, and power quality monitoring systems. Power quality analyzers are handheld devices that measure and record power quality parameters such as voltage, current, harmonics, and transients. Power quality meters are used for long-term monitoring of power quality parameters and can be installed at a specific location to monitor the electrical signals continuously. Data loggers are used for monitoring voltage variations, current fluctuations, and other power quality parameters at high speed and with high accuracy. Finally, power quality monitoring systems provide a comprehensive approach to power quality monitoring and can include a range of sensors and analyzers to monitor different aspects of the power supply.

How Does Power Quality Monitoring Help in Identifying and Solving Power-Related Issues?

Power quality monitoring helps identify and solve power-related issues by detecting and analyzing the electrical signals in a power system. By monitoring power quality parameters such as voltage, current, harmonics, and transients, power quality monitoring can identify power quality problems that can cause equipment failure and downtime. Once the problem is identified, appropriate measures can be taken to solve the issue, such as installing power factor correction equipment or reducing the load on the system. Power quality monitoring can also help identify and solve power-related issues that may take time, such as a gradual degradation of equipment due to poor power quality.

What are the Most Common Power Quality Problems that can be Detected through Monitoring?

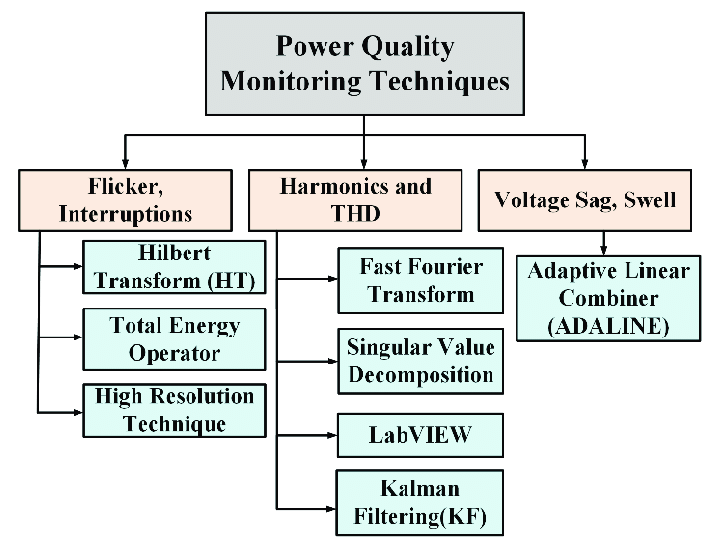

Several power quality problems can be detected through monitoring, including voltage sags, voltage swells, harmonics, transients, frequency variations, and poor power factor. Voltage sags are short-term drops in voltage levels that can cause equipment failure, while voltage swells are short-term increases in voltage levels that can damage equipment. Harmonics are non-sinusoidal components of a power signal that can cause overheating and equipment failure. Transients are short-term variations in voltage levels that can cause equipment failure. Finally, frequency variations can cause equipment malfunction, and poor power factor can lead to higher energy costs.

How Often Should Power Quality Monitoring be Performed, and Who is Responsible for Conducting it?

Power quality monitoring should be performed regularly to ensure a stable power supply and prevent equipment failure and downtime. The frequency of monitoring can depend on several factors, such as the criticality of the equipment, the age of the equipment, the type of power supply, and the environmental conditions. For instance, equipment in a data center may require constant monitoring to prevent downtime, while equipment in a less critical facility may require monitoring at regular intervals.

Power quality monitoring can be performed by electrical engineers or trained personnel with the necessary knowledge and expertise in power systems. The responsibility of conducting power quality monitoring can vary depending on the type of facility and the level of criticality. In some cases, the facility manager may be responsible for monitoring; in others, it may be outsourced to a third-party provider.

The Role of Power Quality Monitoring in Data Centers

Data centers are critical facilities that require an uninterrupted power supply to ensure continuous operation. Poor power quality can cause data center downtime, resulting in huge financial losses. Power quality monitoring is, therefore, crucial in data centers to ensure that the electrical power supplied is stable and reliable. Power quality monitoring can help detect and rectify power-related issues that can cause equipment failure and downtime. The monitoring can also help identify areas for improvement in the power supply infrastructure and optimize energy usage. Additionally, power quality monitoring can assist data center managers in complying with industry standards and regulations related to power quality.

The Importance of High-Speed Data Logging in Power Quality Monitoring

High-speed data logging is a critical aspect of power quality monitoring as it helps capture and analyze electrical signals at high speed and with high accuracy. In addition, high-speed data logging allows for the detection of transients and other fast-changing power quality parameters that may be missed by conventional monitoring equipment. High-speed data logging can also help in the early detection of power-related issues and the optimization of power usage, leading to improved energy efficiency and reduced energy costs.