Medium Voltage Power Cable Testing - Our 12-hour live online instructor-led training course is designed for electrical engineers, electrical technicians, and front-line electrical testing and maintenance specialists who test, install, maintain, repair, or troubleshoot medium and high voltage power cables*. Since power cables are the backbone of the worlds power distribution system, many must learn how cable systems are designed, installed, and tested, as well as the applicable Standards to follow, and how to properly select and perform the appropriate testing methods for their situation.

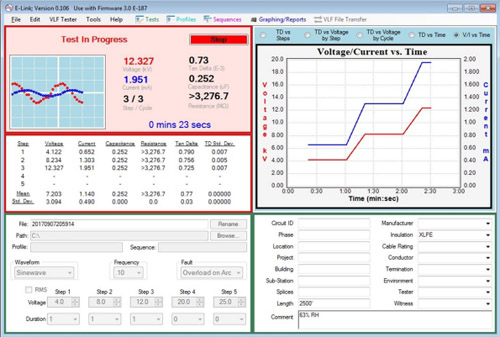

Students will learn of the various methods used to perform mostly off-line cable testing. An overview of all the numerous possible tests available will be offered, followed by a more detailed, comprehensive study of the most prominent technologies and test methods used today. They will learn how to perform and analyze results of insulation resistance tests (DAR & PI), DC hipot tests, Type I withstand tests (DC, AC, & VLF), and diagnostic testing using Tan Delta and Partial Discharge techniques.

Except for Installation over-voltage withstand testing of newly installed systems, most MV/HV cable testing is Diagnostic, or non-destructive, using absolute, trending, and comparative test data usually performed as part of a condition-based electrical maintenance program. Although all methods of cable testing will be explored, our course focuses on the current methods of Withstand, Tan Delta, and Partial Discharge testing using VLF and 50/60 Hz. power frequency techniques for data collection to provide specific defect information and/or the overall condition of the cable.

After attending this course, students will know how to:

* This course is mostly for testing of medium voltage cables, but most of the methods and technologies described are used on HV cable up to ~200 kV in rating.

MV-HV Cable Testing Training Course Outline

DAY ONE

Cables and Cable Systems Described

Why Do We Test Medium and High Voltage Cable

OK, We’ll Test. What Are We Looking For

How to Select Best Method to Use: Different Tests = Different Results

Commonly Used Methods for MV/HV Cable Testing

DAY TWO

Brief Review of Cable Testing Methods & Technologies Available

Technologies & Methods Taught in This Course

VLF Overview, History, and Acceptance

VLF Testing Standards

VLF Withstand & Diagnostic Tests – Which to perform? What is the Desired Result?

VLF Tangent Delta Test – How Good is my Cable Overall? Global Assessment

Partial Discharge Test – Where are the bad spots? Specific Location and Severity

Summary

Review of Expectations

Questions and Answers

COURSE TIMETABLE

Both days:

Start: 10 am ET

Finish: 4:30 pm ET

The registration fee to attend this live online training course is $599 + GST/HST.

Click Here to download a $100 discount coupon that you can apply toward the regular registration fee and pay only $499 + GST/HST

Register 3 delegates at full price $599, and get a 4th registration FREE!

Successful completion of this course qualifies delegates to receive a certificate of course completion with indicated CEUs.

CEUs are granted by the Engineering Institute of Canada. One CEU is equivalent to 10 professional development hours of instruction.

This course earns 1.2 CEUs.