Industrial Automation Training - This 12-Hour Live Online instructor-led course will give students an overview of the main products and technologies that are driving the automation controls market. Students will learn the benefits of existing and emerging hardware and software technologies and best decide which methods to

Industrial Automation is rapidly growing especially within the Power sector, Automobile, Oil and gas, Manufacturing, Mining etc. Process Automation provides the technology to control and monitor the process in industrial plants using concepts such as feedback, cascade, feed forward and advanced process control. According to an estimate provided by the International Society of Automation (ISA), 15,000 fresh automation engineers are required annually in the United States. This Industrial Automation course is designed to empower students with the foundation and intermediate level of knowledge that will help them to understand the three key modules of Industrial Automation: PLC, SCADA, and DCS.

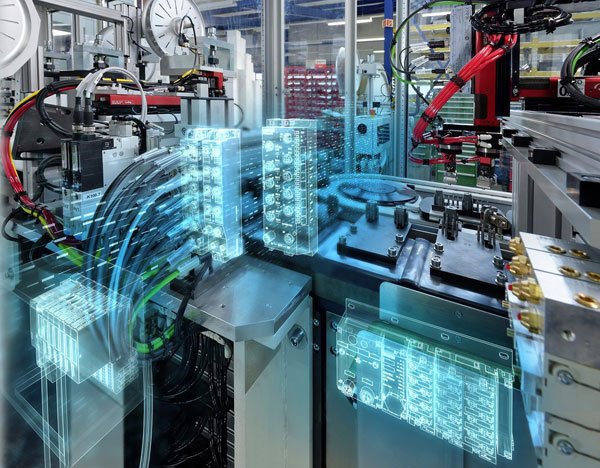

Industrial robotics, controls and automated systems have been in general use in the manufacturing industry since the early 1980s. These industrial automation systems have seen wide acceptance in high-volume manufacturing for many years. As systems mature, they become cost effective for low-volume production in the local manufacturing sector. The integration of automation and industrial control sytems, architectures and protocols has created a specific need to train industrial electrical and instrumentation staff on the development and maintenance of industrial automation systems.

Who is the online Industrial Automation training designed for?

COURSE BENEFITS

Industrial Automation Course

Course Instructor: Paul DeJong C.E.T., Northern Dynamics

Session 1 - PLC’s

Rockwell Automation the Logix Family

Siemens S7-1500 & S7-1200

Omron NX/NJ and other Families

Panasonic

Mitsubishi MELSEC Families

Eaton, Schneider, ABB

Session 2 - HMI’s / Scada

Session 3 – Drives, Motion, Motors and Servos

Siemens, Rockwell, ABB

Energy and maintenance savings

Energy Savings vs Maintenance and overall Costs

Energy Savings vs Pneumatic / Hydraulics

Session 4 - Networks and new Standards

EtherNet/IP, EtherCat, ProfiNet, Modbus/TCP

Profibus, Modbus/RTU, DH+

Session 5 – Sensors and Actuators

IoT and CAN / DeviceNet networks

Session 6 - Safety Products

Process of applying

Light Curtains

Session 7 – Overview of the three main software packages

PLC, HMI and Drive access

Session 8 – Further look at CODESYS and the IEC 61131-3 Standard

Session 9 – HMI and Scada Software

Session 10 – Various Programming Languages

History and use

Variations in Function Block languages

North American vs European vs Asian

Session 11 – Customization of code

Sequential Programming compared to sequencer instructions

Company Based Standards

Visual Basic, C-Based, Python

Web Programming and Integration

SQL Integration

Session 12 – Remote Access and Security

Everything uses Ethernet now which opens more security challenges

New OPC-UA vs OPC and DDE

The registration fee to attend this live online training course is $599 + GST/HST.

Click Here to download a $100 discount coupon that you can apply toward the regular registration fee and pay only $499 + GST/HST

Register 3 delegates at full price $599, and get a 4th registration FREE!

Successful completion of this course qualifies delegates to receive a certificate of course completion with indicated CEUs.

CEUs are granted by the Engineering Institute of Canada. One CEU is equivalent to 10 professional development hours of instruction.

This course earns 1.2 CEUs.