Arc Flash

Arc Flash Breaker: The Ultimate Electrical Safety Solution

Arc flash breaker, also known as an arc fault circuit interrupter (AFCI), detects dangerous electrical arcs and de-energizes the circuit to prevent fires. Unlike a standard breaker, it provides enhanced protection against arc faults in residential and commercial systems.

Quick Definition: Arc Flash Breaker

-

✅ Arc flash breaker: A specialized circuit breaker designed to detect high-energy electrical arcs and rapidly isolate faulted equipment.

-

✅ Enhanced protection: Interrupts arc faults faster than standard breakers, reducing incident energy and protecting workers.

-

✅ Industrial use: Deployed in switchgear, MCCs, and panelboards to meet NFPA 70E and IEEE 1584 safety standards.

An arc flash breaker is a specially designed arc fault circuit breaker that helps reduce the risk of arc flash(AF) incidents by quickly detecting faults and interrupting current flow before dangerous energy levels are reached. These breakers are critical in enhancing electrical safety by limiting incident energy and protecting both personnel and equipment in high-risk environments. The electric discharge flash breaker is one innovative technology that has significantly improved safety measures in the realm of industrial power systems. This advanced device helps protect personnel and property from the hazards of AF incidents. Understanding arc flash protection is essential for maintaining electrical safety and minimizing risks.

Request a Free Training Quotation

How Does an AF Breaker Help Prevent AF Incidents in Electrical Systems?

AF breakers, particularly AF circuit breakers, are designed to detect electrical discharges that could result in hazardous incidents. When an AF is detected, these breakers immediately de-energize the circuit, preventing further damage. An AF breaker is particularly effective in monitoring branch circuits supplying outlets in areas such as family rooms, dining rooms, living rooms, parlours, libraries, dens, recreation rooms, closets, and hallways. Quickly addressing conditions prevents short circuits and the potential for electrical fires. For general electrical safety tips and guidelines, be sure to check out our comprehensive resources.

What Is the Difference Between a Regular Circuit Breaker and an AF Breaker?

A standard circuit breaker is primarily designed to protect against overloads and short circuits by tripping when the current exceeds a certain threshold. However, it does not detect the small electric discharges that can occur in damaged wiring, which may ultimately lead to electrical fires.

In contrast, an AF circuit breaker is designed to detect these smaller electric discharges that would otherwise go unnoticed by a standard circuit breaker. These devices monitor both series and parallel conditions, providing enhanced protection by interrupting the arc fault circuit interrupters before the fault can escalate. This makes AF circuit interrupters, AFCIS, essential for residential electrical systems, especially in areas where electrical fires are a common risk. Electrical breakers play a vital role in protecting systems from faults. Learn more in our article on circuit breaker types.

Do You Select the Right AF Breaker for Your Electrical System?

Selecting the right AF breaker depends on the type of electrical system you are working with and the level of protection required. In residential installations, combination-type AFCIS are typically used. These breakers offer protection from both series and parallel electric discharge faults, which can occur in aging or damaged wiring. The National Electrical Code (NEC) requires AFCIS to be installed in various dwelling unit areas, including family rooms, living rooms, dining rooms, and more.

In addition to AFCIS, a GFCI (ground fault circuit interrupter) may also be installed in locations such as bathrooms to protect against electric shock. A GFCI works by detecting current leakage to the ground and cutting off the power, providing a different form of protection than an AFCI circuit breaker.

What Role Does An AF Breaker Play in Enhancing Workplace Safety?

AF breakers, including AF circuit interrupters, enhance workplace safety by preventing electrical fires and other incidents. In industrial settings, they help protect workers by detecting and interrupting dangerous arcing electric discharges that could lead to severe injuries or damage to equipment. Regular maintenance and installation of these breakers, according to the National Electrical Code (NEC) and National Fire Protection Association standards, ensure a safer working environment. Employers should conduct regular electrical safety audits and electric discharge flash studies to identify potential hazards and implement the correct safety measures, including AFCIs.

How Does An AF Breaker Interact with Other Protective Devices?

AF breakers, particularly electric discharge fault circuit interrupters, often work in conjunction with other protective devices in an electrical system. In residential settings, AFCIs and ground fault circuit interrupters (GFCIs) provide comprehensive protection against both electrical fires and shock hazards. While AFCIs prevent fires by detecting arcing conditions, GFCIs protect people from electrical shock by sensing current leakage to the ground. Click here to learn how to prevent an arc flash from happening in your work environment, follow essential safety protocols and precautions.

In industrial applications, AF breakers can be integrated with overcurrent protective devices and personal protective equipment (PPE) to create a layered approach to safety. By detecting and responding to electrical faults early, AF breakers prevent hazardous incidents, thereby ensuring the protection of both equipment and personnel.

AF breakers are a crucial component of modern electrical systems, offering advanced protection against electric discharge faults that could otherwise lead to hazardous electrical fires. Unlike standard arc fault circuit breakers, AFCIs detect smaller electric discharges and de-energize circuits before a fault can escalate. By following National Electrical Code guidelines and incorporating AFCIs into electrical systems, homes and workplaces can significantly reduce the risks associated with electrical faults. In conjunction with other protective devices, whether in a home or an industrial facility, these breakers create a safer and more reliable electrical system.

For more information on identifying and addressing electrical safety in the workplace, visit our dedicated page.

Related Articles:

Download Our FREE Arc Flash Handbook

Electrical Safety and Arc Flash Handbook Vol. 3

Our third volume on Electrical Safety and Arc Flash directly addresses the industry-wide call for the most up to date information on arc flash prevention, mitigation and injury prevention.

Latest Arc Flash Articles

NFPA 70E Training Requirements

NFPA 70E training requirements ensure that workers are qualified to recognize electrical hazards, use PPE correctly, and follow safety procedures. Training must be updated every 3 years to stay compliant and reduce arc flash and shock risks.

What are the NFPA 70E Training Requirements?

NFPA 70E defines the minimum safety education standards for employees who may be exposed to electrical hazards.

✅ Workers must understand shock, arc flash, and arc blast hazards

✅ Proper PPE selection, care, and usage must be included

✅ Refresher training is required every 3 years, or sooner after changes in job duties or equipment

For a complete overview of the NFPA 70E electrical safety standard, including its history, 2024 updates, PPE categories, and compliance guidelines, see our NFPA 70E guide.

Request a Free Training Quotation

Why NFPA 70E Training Matters

Electrical safety training is not just a box to check—it is essential to reducing workplace injuries and fatalities. By educating employees on risk assessment procedures, safe approach boundaries, lockout/tagout (LOTO), and emergency response, employers can ensure that work is performed safely and in compliance with OSHA requirements.

Failure to comply with NFPA 70E may expose organizations to:

-

OSHA citations and penalties under the General Duty Clause

-

Increased liability after accidents

-

Higher insurance and workers’ compensation costs

-

Damaged reputation and employee trust

Training Content: What Employers Must Cover

A compliant NFPA 70E training program should include:

Hazard Recognition

Identifying exposed energized parts, incident energy levels, and approach boundaries. Workers must also understand approach boundaries, such as the arc flash boundary, which defines the safe distance for preventing injury.

PPE Selection and Use

Determining arc flash PPE categories (CAT 1–CAT 4). Proper PPE must be selected and maintained, including flame-resistant clothing, gloves, balaclavas, face shields, and insulated tools. Refresher training must also cover inspection, maintenance, and replacement of gear.

Safe Work Practices

Establishing an Electrically Safe Work Condition (ESWC). Employers are required to document an arc flash study to calculate incident energy and determine the correct PPE categories. Training also covers lockout/tagout procedures, an essential step before performing energized tasks — see our lockout tagout training article. Risk assessment and job safety planning. Risk assessment and job safety planning are also essential components.

Emergency Response

-

Arc flash incident response.

-

Shock and electrocution first aid.

-

Use of insulating tools and test instruments.

Frequency of NFPA 70E Training

Initial training must be provided before a worker is assigned to tasks involving electrical hazards.

Refresher training must occur at least every 3 years, or earlier if:

-

Job duties change

-

New equipment or technology is introduced

-

An audit reveals safety gaps

-

A worker demonstrates unsafe practices

Frequently Asked Questions

What are the NFPA 70E Training Requirements?

The NFPA 70E standard outlines the requirements for electrical safety programs, training, and the use of personal protective equipment (PPE) in electrical work environments by a qualified person. It also provides guidelines for identifying and assessing electrical hazards, establishing an electrically safe work condition, and selecting and using insulating tools and test equipment. The standard also specifies when arc flash labels must be applied, what safety procedures information those labels must include, and how to select proper PPE based on calculated incident energy or PPE category.

Does NFPA 70e require training?

While NFPA 70E is not law, OSHA enforces electrical safety under the General Duty Clause and references NFPA 70E as best practice. Employers are expected to provide electrical safety program training in safety-related work practices, PPE use, and emergency procedures to qualified electrical workers. Failure to do so may result in citations and liability.

Who Needs NFPA 70E Training?

-

Qualified Workers: Electricians, technicians, engineers, and maintenance staff who work directly on or near energized equipment. Training must include hazard recognition, PPE use, approach boundaries, and lockout/tagout procedures.

-

Unqualified Workers: Non-electrical employees who may enter areas with energized equipment. They must be trained to recognize hazards, respect approach boundaries, and avoid unsafe contact.

Is Arc Flash Training Required Annually?

Yes. NFPA 70E specifies that employees must receive annual instruction on arc flash hazards, incident energy, and PPE. This reinforces safety awareness and ensures consistency across teams.

Related Articles

-

For a broader look at electrical safety in the workplace, visit our NFPA 70E main page

-

For more detail on protective equipment, see our Arc Flash PPE guide

-

To understand the fundamentals, read: What is Arc Flash?

Arc Flash Boundary Chart - Safe Approach Distances

An Arc Flash Boundary Chart outlines the minimum safe distance from energized equipment where a person could be exposed to a thermal incident. This boundary is defined by NFPA 70E and helps determine the required PPE level to reduce the risk of injury.

Request a Free Training Quotation

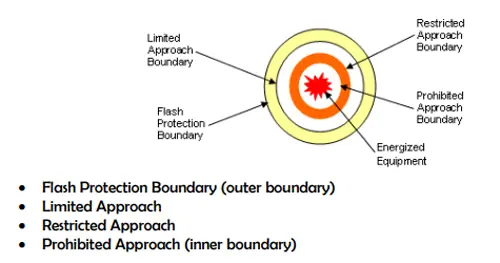

What is an Arc Flash Boundary Chart?

An Arc Flash Boundary Chart is a visual safety reference that outlines critical zones around energized electrical equipment where workers face potential thermal exposure from an arc flash event. These zones are defined by the amount of thermal energy, known as incident energy, that could be released during an electrical explosion. The boundary distance is typically measured in calories per square centimetre (cal/cm²) and directly influences the level of protection required.

✅ Establishes Protection Zones – The chart identifies threshold distances where arc flash hazards begin, helping planners designate safe work limits around equipment.

✅ Supports Risk Assessment – It assists safety professionals in evaluating job site hazards and determining when additional safety controls or energized work permits are required.

✅ Promotes Standardized Safety Practices –The chart helps enforce consistent protection measures across facilities by referencing NFPA 70E and CSA Z462 guidelines.

Each boundary distance shown in the chart corresponds to a specific incident energy exposure level. The farther a worker is from the source, the less energy they are exposed to, meaning reduced PPE requirements. Conversely, close proximity to energized equipment demands more robust arc-rated protective gear.

The arc flash boundary is sometimes called the “protection boundary” or “minimum safe approach distance.” This distance must be calculated individually for each piece of electrical equipment, based on its configuration, voltage level, and available fault current. The boundary is not fixed; it can vary widely between systems, making accurate analysis essential.

Using an Arc Flash Boundary Chart as part of a comprehensive electrical safety strategy ensures that hazard zones are clearly marked, appropriate PPE is used, and only properly trained personnel enter high-risk areas. When integrated with energy assessments and worker training, the chart becomes a practical tool for minimizing injuries and meeting regulatory safety standards.

To delve deeper into the specifics of boundaries, consult our article on Arc Flash Boundary.

Sample Arc Flash Boundary Chart

| System Voltage | Available Fault Current (kA) | Clearing Time (s) | Incident Energy (cal/cm²) | Arc Flash Boundary (AFB) |

|---|---|---|---|---|

| 208V | 15 | 0.1 | 1.5 | 18 inches (1.5 ft) |

| 480V | 10 | 0.1 | 2.8 | 36 inches (3 ft) |

| 600V | 25 | 0.2 | 8.0 | 60 inches (5 ft) |

| 480V | 35 | 0.5 | 12.0 | 96 inches (8 ft) |

| 13.8kV | 5 | 0.1 | 4.0 | 48 inches (4 ft) |

What are AF Boundaries?

The protection zone is the minimum safe distance from energized equipment that an unqualified worker can approach without wearing personal protective equipment (PPE). The NFPA 70E and CSA Z462 standards guide the minimum distances that should be maintained between energized electrical equipment and workers based on the incident energy levels.

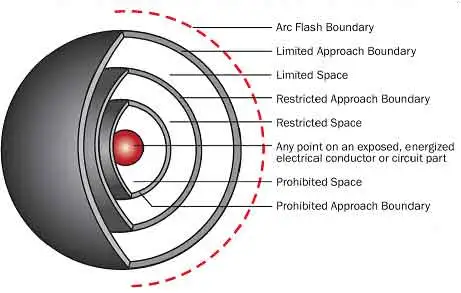

Three protection boundaries are defined by the NFPA 70E and CSA Z462 standards:

Limited Approach Boundary (LAB)—The LAB is the minimum distance from the energized equipment that an unqualified person can approach. This zone is generally marked with a yellow line and is intended to prevent unqualified personnel from entering the hazard zone.

Restricted Approach Boundary (RAB) - The RAB is the minimum distance from the energized equipment a qualified worker can approach without wearing the appropriate PPE. This zone is marked with a red line indicating where a worker must begin wearing the appropriate PPE to prevent injury.

Prohibited Approach Boundary (PAB) - The PAB is the closest distance to the energized equipment considered safe for any person to approach, regardless of PPE. This zone is marked with a black line and indicates the most hazardous area.

What is the Minimum Arc Flash Boundary?

The minimum arc flash boundary is determined by the incident energy level that could be released during an electrical explosion. The incident energy level is calculated using complex mathematical formulas that consider the system voltage, available fault current, and the time it takes for the protective devices to clear the fault.

The NFPA 70E and CSA Z462 standards provide tables and formulas to help calculate the incident energy and the minimum distance. The minimum approach distance is the distance from the energized equipment where the incident energy is below 1.2 cal/cm², which is the level of thermal energy that can cause second-degree burns to unprotected skin. For a breakdown of boundary distances by energy level, refer to our Arc Flash Boundary Table by Incident Energy.

What is the Arc Flash Boundary for 480V?

The protection zone for 480V arc flash equipment can vary depending on the incident energy level. However, the NFPA 70E and CSA Z462 standards provide a table that specifies the minimum distance for 480V equipment based on the available fault current and the clearing time of the protective device.

For example, if the available fault current is 10,000 A and the protective device clearing time is 0.1 seconds, the minimum approach distance for 480 V equipment is 3 feet for a Category 1 PPE level. If you’re working with high-risk levels like 8 cal/cm², see What Is the Arc Flash Boundary for 8 cal/cm²? to ensure proper distance and PPE selection.

It's important to note that the minimum approach distance can vary depending on several factors, including system voltage, available fault current, and protective device settings. Therefore, it's essential to accurately calculate the proper working distance for each piece of equipment to ensure that workers are adequately protected.

How the Arc Flash Boundary Chart Is Used in the Field

The chart serves as a visual reference, enabling safety managers, engineers, and qualified electrical workers to determine safe working distances based on incident energy levels quickly. Typically, the chart displays boundary distances for various voltages, fault clearing times, and working distances. It’s used during risk assessments and job planning to determine the safe distance personnel can be positioned from energized equipment without exceeding the 1.2 cal/cm² threshold. By consulting the chart, professionals can select the appropriate PPE and ensure that labelling and signage accurately reflect the hazard zones. Learn more about Incident Energy and how it affects arc flash risk and PPE requirements.

How to Calculate Boundaries

The chart can be used to calculate the minimum approach distance, but it requires an understanding of the electrical system and its potential hazards. The process involves a detailed analysis of the electrical system and the potential fault currents that could occur.

The NFPA 70E and CSA Z462 standards outline the calculation of the protection zone using various methods, including the incident energy analysis method and the PPE category method.

The incident energy analysis method involves conducting a detailed analysis of the electrical system to determine the potential incident energy levels at various points within the system. This method requires complex calculations and detailed information about the system components, such as the available fault current and protective device settings.

The PPE category method determines the minimum PPE level required for a specific task based on the incident energy level. This method involves using tables to determine the required Personal Protective Equipment (PPE) level for a specific incident energy level and selecting the appropriate PPE based on the task.

Regardless of the method used, accurately calculating this safe distance is critical to ensuring adequate worker safety.

Can an Unqualified Person Cross the AFB?

An unqualified person should never cross the LAB of an energized piece of electrical equipment. The LAB is the minimum distance from the energized equipment that an unqualified person can approach, and it's intended to keep unqualified personnel from entering the hazard zone.

Only a qualified electrical worker who has received specialized training and is authorized to work on or near energized electrical equipment should cross the RAB. Crossing the RAB without appropriate PPE is dangerous and can result in severe burns, injuries, or even death.

Related Pages

Who is at risk of an arc flash?

Who is at risk of an arc flash? Electricians, maintenance technicians, and engineers near energized equipment, switchgear, or substations face hazards from fault current and incident energy; NFPA 70E, PPE, and lockout/tagout mitigate exposure.

Who Is at Risk of an Arc Flash?

Workers near energized equipment—especially electricians and techs—face arc flash risk; NFPA 70E and PPE reduce hazards.

✅ Electricians, E&I techs, and field engineers near live circuits

✅ Workers operating switchgear, MCCs, and substation equipment

✅ Staff performing testing, racking, or maintenance without LOTO/PPE

Who is at risk of an arc flash?

Those at risk of an arc flash include anyone working on or near energized electrical equipment, especially electricians, maintenance personnel, and contractors. Even bystanders may be injured due to blast pressure, fire, or flying debris. For a concise explanation of the phenomenon, see this introduction to arc flash for additional context.

Immediate Threats

The most immediate and severe threat is to those working within the reach of the arc flash. The distance that an arc flash can affect depends on various factors, including the system's voltage and environmental conditions. Conducting an arc flash hazard analysis helps identify these high-risk areas, where stringent precautions, including the use of personal protective equipment (PPE), are necessary. Facilities often mark these zones using floor marking tape or other visual indicators to alert workers of the danger. Detailed definitions of boundaries and hazard categories are outlined in the arc flash hazard guidance for practitioners.

Secondary Threats

In addition to the risk of electrocution, arc flashes pose several secondary threats to those nearby. These threats include:

Understanding the conditions under which an arc flash can occur helps teams tailor lockout procedures and training.

-

Fires: The intense heat from an arc flash can ignite surrounding materials, leading to potentially large fires.

-

Flying Debris: The force of an arc flash or resulting explosion can send debris flying, which can cause serious injuries.

-

Explosions: Arc flashes can trigger explosions, posing further risks to anyone in the vicinity.

These secondary threats can cause immediate harm and set the stage for additional hazards. Further insight into blast dynamics is provided in this arc flash blast and explosion overview for planning and drills.

Tertiary Threats

After addressing the immediate and secondary threats, it's essential to consider the tertiary threats posed by an arc flash. These threats can affect everyone in the facility and even those in the surrounding area. Potential tertiary threats include: A broad technical primer is available in the electrical arc flash fundamentals to frame these broader impacts.

-

Spreading Fires: Fires ignited by an arc flash can spread rapidly, endangering more people and causing extensive damage.

-

Hazardous Chemicals: In facilities that store hazardous chemicals, an arc flash can cause spills or release toxic substances into the air.

-

Structural Damage: The explosion and heat from an arc flash can weaken structural components, posing additional risks.

For prevention, review common initiators such as contamination, loose connections, and improper work practices in what causes an arc flash to inform your corrective actions.

Responding to an Arc Flash

Recognizing the broad range of risks associated with an arc flash underscores the importance of prevention and preparedness. To mitigate these risks, facilities should:

-

Implement Preventive Measures: Regular maintenance, proper insulation, and adherence to safety protocols can reduce the likelihood of an arc flash.

-

Conduct Hazard Analyses: Regularly assessing the facility for arc flash risks helps identify and mitigate potential hazards.

-

Develop Response Plans: Having effective response strategies in place ensures that, if an arc flash occurs, the facility can minimize damage and protect its workers.

Arc flashes pose significant risks not only to those working directly with electrical systems but also to others in the vicinity and potentially the entire facility. By understanding these risks and implementing comprehensive safety measures, facilities can better protect their workers and minimize the dangers associated with arc flashes. Response plans should also address first aid and post-incident care, with lessons summarized in these arc flash victim case insights to strengthen training.

Related Resources

Related Articles

What is an arc flash boundary?

What is an arc flash boundary? It is the NFPA 70E-defined safe working distance where incident energy reaches 1.2 cal/cm², dictating PPE selection, approach limits, arc flash labeling, and electrical safety procedures for energized equipment.

What Is an Arc Flash Boundary?

The arc flash boundary is the NFPA 70E distance where 1.2 cal/cm² incident energy requires PPE and controls.

✅ Defined by NFPA 70E based on incident energy analysis

✅ Requires PPE, signage, and energized work permits inside boundary

✅ Adjusted by fault current, clearing time, and working distance

The term arc flash boundary may sound like technical jargon, but its meaning and evolution have been crucial in shaping modern electrical safety practices. While it’s now a defined safety zone in NFPA 70E and CSA Z462, its origins and significance have a deeper story rooted in the effort to prevent catastrophic workplace injuries. For a plain-language primer on concepts and terminology, the Arc Flash Boundary overview outlines definitions, history, and key safety implications.

Historical Development of the Term

Before the adoption of NFPA 70E, the concept of arc flash hazards received little formal recognition in workplace safety programs. Electrical safety focused primarily on shock hazards, with boundaries defined only in terms of approach distances to energized conductors. To understand how both thermal and shock boundaries are set, see the guide to determining arc flash and electric shock protection boundaries for methodology and examples.

That began to change in the 1990s, as awareness grew around the dangers of arc flash — high-energy explosions caused by electrical faults. Researchers, particularly those involved in IEEE 1584, helped quantify the risks and the amount of incident energy workers could be exposed to during such events. For engineers performing studies, the arc flash boundary calculation resource details equations, assumptions, and data inputs.

With the 2000 publication of NFPA 70E, the arc flash boundary was formally introduced as a critical protection zone — defined as the distance at which a worker could receive 1.2 cal/cm² of incident energy, the threshold for a second-degree burn. In 2015 and later updates, this definition was refined, and emphasis shifted from rigid tables to calculated boundaries based on incident energy analysis, incorporating real-world equipment and system data. When quick lookups are needed, the incident energy boundary table can help verify results and inform PPE selection.

CSA Z462, Canada's parallel standard, adopted similar language and principles, aligning the term across North America and reinforcing its use in both industrial and commercial environments. This alignment also clarifies distinctions from the Limited Approach Boundary, which addresses shock hazards under separate criteria.

Why Does It Matter?

For electrical workers, knowing where the arc flash boundary lies is not theoretical — it’s life-saving. This boundary determines when and where personal protective equipment (PPE) is required and defines safe work distances. It shapes:

-

Job planning and risk assessment

-

The selection of arc-rated clothing and equipment

-

Decisions about energized vs de-energized work

-

Signage, labeling, and physical barriers in the field

In day-to-day tasks like opening panels or performing diagnostics, the arc flash boundary informs whether a worker must don a full arc-rated suit or can proceed with minimal PPE. It also supports supervisors and safety coordinators in enforcing compliant work procedures. For field implementation, the guidance on marking off arc flash boundaries covers labeling, barricades, and temporary controls.

In short, it translates complex hazard calculations into clear, actionable field instructions that protect lives.

Common Misconceptions About Arc Flash Boundaries

Despite its widespread use, the term still carries confusion. Here are a few common misconceptions:

-

“It’s the same as the Limited Approach Boundary.”

False. The Limited Approach Boundary addresses shock hazards. The Arc Flash Boundary relates specifically to thermal energy exposure. -

“All arc flash boundaries are 18 inches.”

Not true. While 18 inches is a common working distance for calculating incident energy, arc flash boundaries vary depending on system voltage, fault current, clearing time, and equipment condition. Practitioners often consult the arc flash boundary chart to visualize how these variables shift distance across equipment types. -

“If I’m outside the arc flash boundary, I don’t need to worry.”

That’s misleading. While PPE may not be required beyond the boundary, awareness and training are still critical. Arc blast pressure, flying debris, and indirect injuries remain possible. -

“Once labeled, a boundary never changes.”

Incorrect. Labels must be updated after system changes, new hazard analyses, or NFPA/CSA standard updates. Assumptions based on outdated data can be dangerous.

The arc flash boundary is more than a technical term — it is a dynamic tool born out of decades of research and tragedy. Its importance continues to grow as electrical systems evolve and safety regulations adapt. By understanding where it came from, what it means, and how to apply it, we can bridge the gap between compliance and true workplace safety.

Would you like a new meta title and description for this updated version?

Visit our Arc Flash Boundary main page for more detailed information on calculating boundaries, protection zones, compliance requirements, and real-world application examples.

Related Articles

OSHA Arc Flash Requirements: What You Need to Know

OSHA arc flash requirements address NFPA 70E compliance, risk assessment, arc flash labeling, PPE categories, approach boundaries, incident energy analysis, training, and lockout/tagout to control electrical hazards and prevent catastrophic injuries.

What Are OSHA Arc Flash Requirements?

OSHA arc flash requirements mandate risk assessment, NFPA 70E controls, labeling, and PPE to reduce electrical injuries.

✅ Conduct arc flash risk assessment per NFPA 70E

✅ Label equipment with incident energy and boundaries

✅ Provide PPE, training, and energized work permits

OSHA arc flash requirements are a set of federal electrical safety regulations designed to reduce the risk of injuries in the workplace. These standards require employers to conduct hazard analyses, identify incident energy levels, enforce lockout/tagout procedures, and provide workers with the appropriate personal protective equipment (PPE). Meeting these requirements is essential for OSHA compliance, protecting employees from serious burns and electrocution, and maintaining a culture of safety in industrial and commercial facilities. To understand the broader standards that support OSHA's rules, visit our page on NFPA 70E. For a concise overview of employer obligations, see the NFPA 70E arc flash requirements summary for practical references.

Request a Free Training Quotation

OSHA Standards and Requirements

OSHA has specific standards for electrical safety that employers must follow to protect their employees from flash and shock hazards. One such standard is the Lockout/Tagout (LOTO) standard. This standard requires employers to ensure that machines or energized electric equipment are properly de-energized and locked or tagged out during maintenance, servicing, or repair to prevent accidental startup or release of stored energy. Lockout/tagout compliance is critical for accident prevention; see our in-depth guide on OSHA 1910.147 In addition, for broader context on enforcement priorities and safe work practices, review our OSHA electrical safety overview to align your program.

OSHA Arc Flash Requirements also require employers to provide safety-related work practices for employees working on or near exposed energized parts. These safety-related work practices include the use of personal protective equipment (PPE) and adherence to specific procedures to prevent electrical hazards. Additionally, OSHA requires employees who work with electricity to be qualified and trained in safe work practices. A qualified person has the necessary skills and knowledge to work safely on electrical systems. To match PPE selection with calculated incident energy, consult this arc flash levels of protection guide for category-to-gear mapping.

OSHA Compliance

Effective compliance with OSHA electrical standards requires more than just awareness — it demands a structured approach that includes arc flash training, hazard identification, and proper implementation of safety procedures. One of the key components of any workplace safety plan is conducting an arc flash hazard analysis to determine potential exposure risks and calculate incident energy levels. This process helps employers understand the severity of electrical hazards present. It guides the selection of appropriate personal protective equipment (PPE), such as flame-resistant clothing and arc-rated face shields.

In addition to following OSHA rules, companies are expected to align with NFPA 70E compliance requirements, which outline industry best practices for minimizing electrical hazards. These standards are closely aligned with electrical safety regulations that outline employer responsibilities, including labelling equipment, posting warning signs, and ensuring workers are qualified for tasks involving energized systems. When regular audits and updated procedures reinforce arc flash training, organizations can create a safer work environment and meet both regulatory and operational goals. Many employers benchmark procedures against NFPA 70E guidance to keep policies consistent and auditable.

OSHA Arc Flash Compliance Checklist

While NFPA 70E provides the foundation for electrical safety, OSHA enforces compliance. The checklist below outlines OSHA-specific actions employers must take to meet arc flash safety obligations.

Use this checklist to assess whether your facility is meeting OSHA arc flash requirements and aligning with NFPA 70E compliance standards.

1. Hazard Identification and Risk Assessment

-

Has a complete arc flash hazard analysis been performed for all energized equipment above 50 volts?

-

Are incident energy levels calculated and documented for each location?

-

Have electrical shock and arc flash risks been clearly identified?

2. Labeling and Signage

-

Are all electrical panels and equipment labeled with arc flash warning labels?

-

Do labels include incident energy, arc flash boundary, working distance, and PPE category?

3. Personal Protective Equipment (PPE)

-

Are workers provided with appropriate arc-rated personal protective equipment (PPE) based on the calculated incident energy?

-

Does all PPE meet NFPA 70E and ASTM F1506 standards?

-

Is PPE inspected regularly and replaced when it is damaged or expires?

4. Electrical Safety Program

-

Do you have a written electrical safety program that addresses arc flash hazards?

-

Does the program include safe work practices, lockout/tagout procedures, and energized work permits?

-

Is the program reviewed and updated at least once every 3 years?

5. Arc Flash Training

-

Have all qualified workers received arc flash training in the last three years?

-

Does training include hazard recognition, PPE use, and emergency procedures?

-

Are training records current and accessible?

6. Tools and Test Equipment

-

Are workers using insulated tools and test equipment rated for the voltages involved?

-

Are instruments calibrated and in proper working condition?

7. Lockout/Tagout (LOTO) Procedures

-

Are lockout/tagout procedures documented and enforced per OSHA 1910.147?

-

Are authorized employees trained in energy isolation and verification steps?

For a step-by-step guide to meeting electrical safety standards, explore our in-depth NFPA 70E Compliance Checklist.

Arc Flash Hazard Analysis

Under OSHA Arc Flash Requirements, Employers must conduct a hazard risk analysis to protect employees from electrical safety hazards. This analysis helps determine the risk of an electrical explosion occurring and the incident energy level that could result from it. Incident energy could be released during an arc flash, measured in cal/cm². A qualified person must perform the arc flash hazard analysis. For clarity on when a study is necessary under federal rules, see whether an arc flash analysis is required by OSHA for decision points.

Safety Training

OSHA dictates that employers provide training for employees working on or near exposed energized parts. This training must include electrical safety-related work practices, the use of personal protective equipment (PPE), and lockout/tagout procedures. The training must be provided to employees before they begin work and periodically after that to ensure they are aware of the hazards and how to protect themselves from electrical hazards. Employers must also ensure workers receive proper instruction. An example of this can be read on our Electrical Safety Training page. Supervisors can verify competency through recognized arc flash training certification pathways that document qualifications.

Frequently Asked Questions

How often does OSHA require an arc flash study?

OSHA does not specify a required frequency for performing an arc flash study. However, OSHA does require employers to perform a hazard risk assessment to determine the potential risk of an electrical explosion and the incident energy level that could result from it. An incident energy level is the amount of thermal energy an arc blast could produce, measured in calories per centimetre squared (cal/cm²).

A qualified electrical engineer should perform a power system study whenever a new electrical system is installed or when changes are made to the existing system that could affect the potential incident energy. Employers should also conduct an analysis when a change in work practices or procedures could increase the risk of an arc flash event. For planning intervals and triggers, reference this arc flash study requirements resource to schedule updates.

Therefore, it is essential for employers to regularly review their electrical systems and work practices to determine if a study is necessary to ensure the safety of their employees.

What is the OSHA regulation for arc flash?

OSHA has specific regulations that employers must follow to ensure the safety of their workers. The OSHA regulation for arc flash is outlined in the Code of Federal Regulations (CFR) 29, specifically in CFR 1910.333.

CFR 1910.333 requires employers to protect employees from potential electrical hazards, including electric shock and flash, when working on or near exposed energized parts. Employers must provide employees with appropriate safety-related work practices, personal protective equipment (PPE), and training to protect them from these hazards.

Employers must perform an analysis to determine the level of potential hazard. This analysis helps identify the potential hazards of working on or near exposed energized parts, such as the incident energy level resulting from an accident.

OSHA also requires employers to follow consensus standards, such as the National Fire Protection Association's (NFPA) 70e standard, to ensure that their employees are protected from electrical hazards. The NFPA 70e standard provides guidance on electrical safety-related work practices, including PPE and training requirements.

Overall, OSHA arc flash regulations are in place to protect employees from electrical hazards, including arc flash hazards. Employers must comply with these regulations to ensure the safety of their workers when working on or near exposed energized parts.

Related Articles:

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.

Related Articles

NFPA 70e Compliance Checklist

NFPA 70E Compliance Checklist outlines essential steps for electrical safety, including arc flash analysis, training, PPE, and labeling. It helps employers meet OSHA requirements, protect workers, and build a sustainable electrical safety program.

What is an NFPA 70E Compliance Checklist?

The NFPA 70E Compliance Checklist is a structured guide that helps organizations implement safety programs, meet OSHA regulations, and reduce arc flash risks.

✅ Defines electrical safety program requirements

✅ Ensures training, PPE, and hazard labeling

✅ Supports OSHA and NFPA 70E compliance

NFPA 70E Compliance Checklist

Implementing NFPA 70E regulations is more than simply knowing the standard. It requires a step-by-step compliance strategy that aligns with OSHA arc flash requirements, protects workers, and establishes a sustainable electrical safety program. Many companies struggle with where to start. This checklist provides a roadmap for both immediate and long-term action. For a complete overview of NFPA 70E electrical safety standards, see our NFPA 70E overview page

Short-Term Actions

Compliance begins with basic precautions that can be adopted right away:

-

De-energize whenever possible – Electrical work should be performed on equipment that is locked out and verified safe.

-

Avoid synthetic fabrics – Until proper PPE is issued, workers should at a minimum wear natural fibres, such as cotton, to reduce burn severity.

-

Use temporary labels – Apply interim arc flash hazard warning labels to equipment until full labeling requirements are met.

These steps won’t make a facility fully compliant, but they reduce immediate risks while longer-term measures are implemented.

Long-Term Actions

Building a sustainable compliance program requires investment and planning:

-

Train employees – Conduct NFPA 70E arc flash training for qualified and affected workers.

-

Review lockout/tagout (LOTO) procedures – Ensure control panels and equipment are properly covered, and update your LOTO programs.

-

Audit tools and PPE – Verify that workers have voltage-rated tools, insulated equipment, and appropriate arc-rated clothing.

-

Perform an arc flash hazard analysis – Determine incident energy levels and establish arc flash boundary.

-

Label equipment permanently – Once hazard data is established, equipment should be clearly marked with durable NFPA 70E-compliant labels.

The NFPA 70E Compliance Checklist – 7 Steps

To meet the intent of OSHA and NFPA 70E, organizations should implement a structured program:

-

Develop an Electrical Safety Program

Document a written program that outlines roles, responsibilities, and procedures. -

Conduct Arc Flash Assessments

Create a single-line diagram, calculate incident energy, and label equipment. See our guide on arc flash assessment for details. -

Train and Qualify Employees

Ensure ongoing training for both qualified and unqualified personnel, with records of completion. -

Provide PPE and Tools

Supply the correct arc flash PPE, insulated equipment, and voltage-rated tools. -

Establish Preventive Maintenance

Develop a proactive maintenance program to mitigate equipment failure risks that can lead to arc flash events. -

Implement Mitigation Strategies

Use engineering solutions, such as current-limiting breakers or arc-resistant equipment, to reduce incident energy. -

Manage Change and Continuous Improvement

Update safety programs, retrain employees, and revise risk assessments whenever systems or conditions change.

Why This Matters

NFPA 70E compliance is not a one-time exercise. It is an ongoing cycle of assessment, training, and improvement. Companies that fail to adopt a structured approach risk OSHA citations, costly downtime, and — most importantly — preventable worker injuries.

By following this compliance checklist, organizations can move from temporary stopgaps to a fully developed electrical safety program that not only meets NFPA 70E requirements but also creates a safer, more reliable workplace.

For more information, explore our Arc Flash Electrical Safety Channel.

Related Articles