Arc Flash Labels Explained

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

Arc flash labels warn workers of electrical hazards by displaying incident energy, PPE requirements, and approach boundaries. NFPA 70E and OSHA standards require these safety labels to improve compliance and reduce arc flash accident risks.

What are Arc Flash Labels?

Arc flash labels are essential for communicating electrical hazards in workplaces, and may also be referred to as electrical panel labels or safety warning labels in compliance programs.

✅ Identify arc flash hazard levels and PPE needs

✅ Display approach boundaries for electrical safety

✅ Support NFPA 70E and OSHA compliance requirements

Request a Free Training Quotation

Arc flash labels are not just compliance items—they must also satisfy NFPA 70E labelling requirements, which state that every energized electrical panel likely to be serviced requires a clear hazard label. Aligning with ANSI Z535 standards enhances clarity, for example, by using signal words like DANGER for high-risk hazard situations and WARNING for moderate risks. Whether placed on industrial switchboards or motor control centers, well-crafted electrical hazard warning stickers support quick recognition and safe work planning.

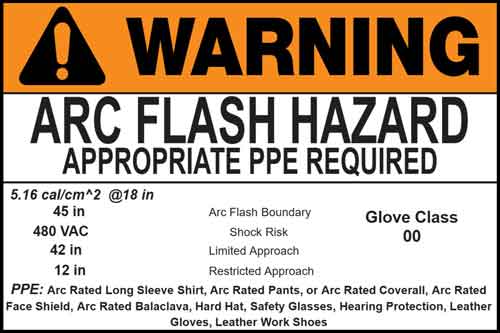

Beyond placement, they need to convey specifics like PPE category labelling or incident energy marking requirements. For example, a label may denote a 25 cal/cm² boundary for Category 3 protection. Such equipment hazard signage plays a critical role in high-energy environments—like manufacturing plants, data centers, and utilities, by signalling required safety precautions before maintenance begins.

Crucial Information

Arc flash labels provide information such as voltage, incident energy, and PPE requirements, fulfilling AF labeling requirements for industrial facilities, manufacturing plants, and data centers. By following the labelling specifications set forth by NFPA 70E Arc Flash Label Requirements and keeping the analysis or study up to date, employers can help ensure that workers are protected from the risks of electrical explosion and other electrical hazards.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

AF and shock hazards pose serious safety risks to anyone working on or near energized electrical equipment. To help prevent injury or death, read our What is Arc Flash Labelling article, which clearly identifies potential hazards and documents the required personal protective equipment (PPE) needed before any work begins.

Arc Flash Labeling for Electrical Panels and Equipment

Arc flash labels are essential hazard signage for identifying shock and electrical hazard risks on energized electrical equipment. In compliance with NFPA 70E and OSHA AF labelling requirements, these safety warning plates communicate critical details such as incident energy, arc rating, PPE category, and approach boundaries. Proper equipment labelling not only ensures compliance but also helps protect workers in industrial facilities, manufacturing plants, and data centers where electrical hazards are common.

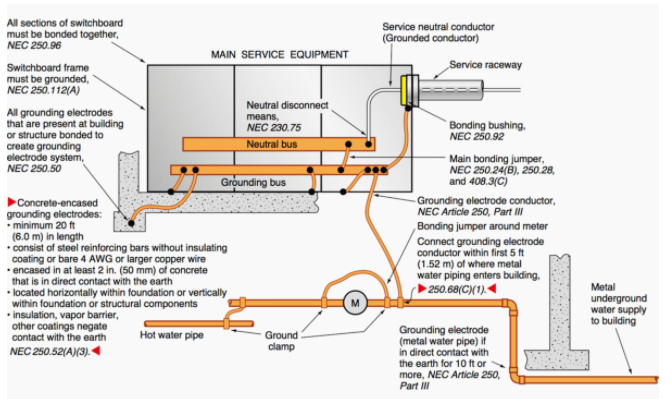

An arc flash label must be securely attached to the electrical panel or relevant equipment, remaining legible even in challenging environments. These decals display vital information — including nominal system voltage, restricted approach boundary, and incident energy levels in cal/cm² — enabling workers to select the right PPE before performing maintenance. In many cases, customized electrical panel labels can include site-specific hazard data from a hazard analysis or study, ensuring the signage reflects actual conditions and remains accurate over time.

Placement and Visibility

Electrical equipment is often labelled with warnings about potential hazards and indicate that specific PPE and tools are required. They must be durable and remain legible in harsh environments, functioning as hazard signage that withstands heat, moisture, and abrasion. The markers should be placed in a location that is easily visible and readable from a safe distance. Consistency in the labels’ format and location also helps comply with PPE specifications. Our When is Equipment Labeling Required for Arc Flash Hazards? guide explains which equipment types and conditions must have hazard labels.

Arc Flash Label Components and Compliance Requirements

| Label Element | Purpose | NFPA 70E/OSHA Requirement | Example Information Shown |

|---|---|---|---|

| Incident Energy Rating | Shows calculated heat energy from an AF | Must be displayed in cal/cm² | 8.5 cal/cm² |

| PPE Category | Indicates minimum PPE needed for protection | Required for worker safety compliance | Category 2 PPE |

| Approach Boundaries | Defines safe working distances for qualified persons | Required to prevent accidental contact | Limited: 42 inches, Restricted: 12 inches |

| Equipment Identification | Identifies specific panel, breaker, or equipment | Helps trace hazard source and maintenance logs | Panel ID: SWBD-01 |

| Date of Analysis | Shows when AF study was last conducted | Ensures up-to-date hazard assessment | July 2024 |

NFPA 70E Minimum Label Requirements

NFPA 70E labeling requirements ensure that every energized panel or piece of equipment has hazard signage displaying voltage, approach boundaries, and PPE details. Many companies also follow ANSI Z535 standards for color codes and signal words, which makes these electrical hazard warning stickers clear and consistent.

OSHA requires arc flash safety signs and equipment hazard signage in any facility where workers may be exposed to electrical risks. This includes PPE category labeling and incident energy marking requirements, so that anyone approaching the equipment can quickly identify the correct protective gear.

NFPA 70E-2021 Article 130.5(H) outlines the minimum specifications for arc flash labelling and the information that must be included on the label. At a minimum, the label must display:

-

Nominal system voltage

-

Restricted approach boundary

-

Hazard-appropriate PPE

Additionally, the label must include at least one of the following:

-

Available incident energy and the corresponding working distance

-

AF PPE category from NFPA 70E Table 130.7(C)(15)(a) or Table 130.7(C)(15)(b) (but not both)

They should follow NFPA 70E standards for format and content, which specify equipment labelling details for AF safety. The minimum arc rating of clothing and the site-specific PPE level must also be listed. For more on these specifics, see Arc Flash Warning Label for examples of compliant label designs.

Design, Size, and Customization

Although NFPA 70E does not specify label size, location, or quantity, it’s important they remain clearly visible and easy to read. Many facilities choose custom label templates to ensure their design meets arc flash labelling and electrical safety best practices. While including shock risk assessment information is common, it is not required by NFPA 70E.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Exceptions and Alternate Documentation

An exception in 130.5(H) allows other forms of documentation instead of signs in supervised industrial installations. For example, if a maintenance mode setting is used to reduce incident energy and PPE requirements, the label must clearly indicate this, or it should show the worst-case energy release, with the maintenance mode reduction detailed in the Energized Work Permit.

Accuracy and Updating

One of the key steps in an AF analysis is ensuring that the correct label is applied to each piece of electrical equipment. The equipment names on the one-line diagram should match those on the labels to avoid errors.

NFPA 70E requires studies to be reviewed for accuracy whenever power system changes occur and at least once every five years. It is not necessary to update them solely because NFPA 70E specifications change—only if the electrical system itself has been modified.

For detailed compliance solutions, see Arc Flash Analysis and Labeling Solutions.

Related Context for Safety

A key distinction is explained in Arc Flash vs Arc Blast, showing how pressure waves add to the danger of AF incidents.

The risk of uncontrolled discharge is especially high in systems with high fault current capacity and where NFPA 70E and CSA Z462 safety procedures are not followed.

Explore the role of electrical explosions in accidents and how they threaten safety.

Learn more in our Arc Flash PPE Clothing guide.

With proper maintenance, hazard assessment, and compliance to NFPA 70E, CSA Z462, and IEEE 1584, these events are largely preventable.

Related Articles