Automatic Power Factor Controller

Automatic power factor controller improves energy efficiency by maintaining optimal power factor in electrical systems. It automatically adjusts capacitor banks to reduce losses, lower electricity bills, and enhance load performance.

What is an Automatic Power Factor Controller?

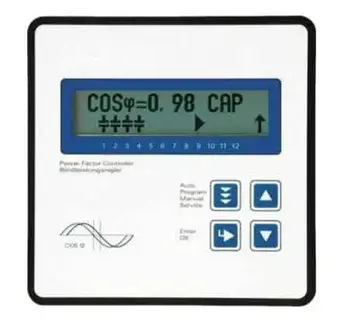

An automatic power factor controller (APFC) is a device that maintains the desired power factor in electrical systems by switching capacitor banks in response to load demand.

✅ Improves energy efficiency by reducing reactive power losses

✅ Automatically adjusts capacitors to stabilize power factor

✅ Reduces electricity costs and prevents power penalties

To better understand how power factor affects your electrical system, see our guide on how power factor is calculated.

An Automatic Power Factor Controller (APFC) is an essential device that regulates reactive power and optimizes electrical networks. They improve electrical efficiency, reduce energy consumption, and increase the lifespan of electrical equipment. The installation and maintenance of APFC must be done correctly to ensure that the system operates within the specified parameters. There are two main types of APFC available in the market - fixed and automatic. Automatic APFC is the most commonly used type due to its flexibility and energy-saving capabilities. APFC panel is necessary to house the APFC and the components required for the system to function. Using a properly rated capacitor bank is crucial for effective APFC operation and maintaining a consistent power factor.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

APFCs offer several benefits that make them an essential component of electrical networks. They improve the power factor (PF) of the electrical system, reduce energy consumption, improve the lifespan of electrical equipment, and filter out harmonics. However, the installation and maintenance of APFC must be done correctly to ensure that the system operates within the specified parameters. APFCs are available in different types, and automatic APFCs are the most commonly used due to their flexibility and energy-saving capabilities. Additionally, using an APFC panel simplifies the installation process and ensures the system operates efficiently. Overall, APFCs are an excellent investment for businesses seeking to reduce energy consumption and enhance electrical efficiency.

PF correction is a vital aspect of electrical networks that are often overlooked. An inefficient PF leads to energy wastage, increased electricity bills, and potential damage to electrical equipment. To address these issues, APFC have been developed to regulate reactive power and optimize electrical networks. In this article, we will delve into the details of APFC, its benefits, types, and installation process. For a complete overview of energy efficiency and PF correction, visit our power quality knowledge center for articles, tools, and training.

Frequently Asked Questions

What is an APFC, and how does it work?

An APFC is a device used to regulate and maintain the PF of an electrical network. The PF is the ratio of real power to the apparent power in a circuit. The ideal PF is 1, meaning all the electrical energy is used effectively. However, in many electrical systems, the PF is less than 1, resulting in wasted energy. Learn the differences between apparent power vs real power to understand why APFCs play a crucial role in improving system performance.

APFC works by controlling the reactive power of the electrical system. Reactive power is the portion of apparent power that does not contribute to real power and is necessary to function in certain electrical equipment. APFC measures the PF of the electrical system and calculates the amount of reactive power required. It then switches on or off the capacitor banks connected in parallel with the load to maintain the desired PF. Explore how lagging power factor can increase energy costs and how APFCs help mitigate this issue.

What are the benefits of using an APFC?

Using APFC brings several benefits to the electrical network. Firstly, it improves electrical efficiency by reducing the amount of reactive power consumed by the system. This results in significant energy savings and lower electricity bills. Secondly, APFC improves voltage regulation by stabilizing the supply voltage and reducing the likelihood of voltage fluctuations. Thirdly, APFC reduces the load on electrical equipment by optimizing the PF. This improves the lifespan of the equipment and reduces the risk of damage. Finally, APFC filters out harmonics that may be present in the electrical system. Harmonics are unwanted frequencies that can cause disturbances and damage to the electrical system.

How do you calculate the required capacity of an APFC?

The required capacity of an APFC can be calculated using the following formula:

Required kVAR = kW x tan(cos⁻¹(PF) - cos⁻¹(desired PF))

Where: kW is the actual power consumption of the load in kilowatts, PF is the actual PF of the load desired; PF is the desired PF of the electrical system.

This formula calculates the amount of reactive power the system requires and the corresponding size of the capacitor banks needed for APFC. It is important to note that the capacitor banks must be rated for the correct voltage and frequency of the electrical system. Improve your calculations with our power factor calculator to size APFCs accurately based on your system's demand.

What are the different types of APFCs available in the market?

Two main types of APFC are available in the market - fixed and automatic. Fixed APFC is designed to maintain a constant PF, typically between 0.95 and 0.98. It operates continuously and cannot adjust to varying loads. Automatic APFC, on the other hand, can adjust to the varying loads of the electrical system. It measures the PF in real-time and switches on or off the required number of capacitor banks to maintain the desired PF. Automatic APFC is the most commonly used type due to its flexibility and energy-saving capabilities.

How do you install and maintain an APFC?

The installation process of an APFC involves connecting the capacitor banks in parallel with the load and installing the controller panel. The controller panel houses the APFC and the necessary components for the system to function, such as relays and switches. Therefore, it is essential to ensure that the APFC is rated for the correct voltage and frequency of the electrical system.

Maintenance of the APFC involves regular checks of the capacitor banks, relays, and switches to ensure they function correctly. The control panel must also be kept clean and free of dust and debris that may affect the components' performance. The APFC must be calibrated periodically to ensure it operates within the specified parameters.

What does an APFC do?

An APFC is a device that regulates the PF of an electrical system by controlling the amount of reactive power consumed by the system. The APFC measures the PF in real-time and switches on or off the required number of capacitor banks to maintain the desired power factor. This results in improved electrical efficiency, reduced energy consumption and increased lifespan of electrical equipment.

What are the advantages of an APFC?

Using automatic power factor controllers brings several advantages to the electrical system. Firstly, it improves electrical efficiency by reducing the amount of reactive power consumed by the system. This results in significant energy savings and lower electricity bills. Secondly, it improves voltage regulation by stabilizing the supply voltage and reducing the likelihood of voltage fluctuations. Thirdly, it reduces the load on the electrical equipment by optimizing the PF. This improves the equipment's lifespan and reduces the risk of damage. Finally, automatic power factor controllers filter out harmonics that may be present in the electrical system. Harmonics are unwanted frequencies that can cause disturbances and damage to the electrical system.

How does APFC work?

APFC works by measuring the PF of the electrical system and calculating the amount of reactive power required. It then switches on or off capacitor banks connected in parallel with the load to maintain the desired power factor. Automatic PF correction is achieved through a mechanical power factor controller, which measures the PF in real-time and adjusts the capacitor banks accordingly.

Why is an APFC panel needed?

The APFC panel is required to house the system's APFC and functional components, including relays and switches. It also provides a centralized location for monitoring and controlling the PF of the electrical system. Using an APFC panel simplifies the installation process and ensures the system operates correctly.

Related Articles

On-Site Training

Interested in cost effective, professional on-site electrical training?

We can present an Electrical Training Course to your electrical engineering and maintenance staff, on your premises, tailored to your specific equipment and requirements. Click on the link below to request a Free quotation.

EF PARTNER MEDIA

Product Showcases

Shared Media