Utility Transformers

Power Transformer Explosion Causes And Prevention

Power transformer explosions pose a serious risk to electrical substations, causing fires, equipment damage, and power outages. Proper maintenance, insulation monitoring, and the use of protective relays help reduce hazards and improve grid reliability.

What is a Power Transformer Explosion?

A power transformer explosion is a catastrophic failure in high-voltage equipment that can result from insulation breakdown, overheating, or internal arcing.

✅ Leads to fire, smoke, and equipment destruction

✅ Causes blackouts, downtime, and safety hazards

✅ Preventable with testing, monitoring, and protection

A power transformer explosion is a serious concern for industrial electricians, posing a significant safety hazard and the potential for widespread power outages. Understanding the causes, consequences, and preventative measures associated with these incidents is crucial for maintaining a safe working environment and ensuring the reliable operation of electrical systems. Let's examine the causes of explosions, covering key topics such as common causes of failure, the devastating effects of explosions, essential safety features, and best practices for maintenance, inspection, and prevention. By gaining a deeper understanding of these critical aspects, industrial electricians can enhance their knowledge, improve safety protocols, and contribute to preventing catastrophic transformer failures.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Causes of Transformer Explosions

A power transformer explosion can occur due to various internal and external factors. Internal faults, such as insulation breakdown, short circuits within the windings, and overheating due to excessive current flow, can trigger a catastrophic failure. External factors, including lightning strikes, power surges from the grid, and even animal intrusion, can also damage the unit and lead to an explosion. Overloading the unit beyond its designed capacity, as well as poor maintenance practices that neglect regular inspection and upkeep, can significantly increase the risk of such incidents. Many failures occur in high-voltage environments, making a substation transformer especially prone to catastrophic explosions if not properly maintained.

Effects of Transformer Explosions

The effects of a transformer explosion can be devastating. The immediate consequence is often a widespread power outage, disrupting electricity supply to homes, businesses, and critical infrastructure. The intense heat and release of flammable oil during an explosion can ignite fires, causing further damage to property and endangering lives. Additionally, transformer explosions can lead to environmental damage due to oil spills and the release of toxic gases, posing risks to both human health and ecosystems. The safety hazards associated with these events cannot be overstated, as explosions can cause serious injuries or even fatalities to people in the vicinity. Regular monitoring, such as using a hydrogen detection system, can help identify early fault conditions that often lead to explosions.

Transformer Safety Features

To mitigate the risks associated with transformer explosions, various safety features are incorporated into the design of transformers. Pressure relief valves are crucial components that release excess pressure buildup inside the unit tank, preventing it from rupturing. Buchholz relays act as sensitive detectors, sensing gas accumulation within the device, which often indicates an internal fault, and triggering a trip mechanism to isolate the faulty equipment. Overcurrent protection devices, such as fuses and circuit breakers, interrupt excessive current flow, preventing overheating and potential explosions. Preventive measures, such as condition monitoring, in an age of modernization provide operators with tools to detect insulation breakdowns and prevent failures.

Transformer Maintenance and Inspection

Regular maintenance and inspection are vital for ensuring the safe and reliable operation of power transformers. This includes visual checks for signs of damage or deterioration, oil analysis to assess its condition and identify potential issues, and electrical testing to evaluate the integrity of the unit's insulation and windings. Preventive maintenance, including cleaning, tightening connections, and replacing worn-out components, is crucial in preventing premature failures. Proper training for personnel working with transformers is crucial to ensure they understand the risks involved and follow safe operating procedures. The role of transformer insulation is crucial, as its deterioration is one of the leading causes of transformer explosions.

Transformer Types and Applications

Power transformers come in various types, each designed for specific applications. Large power transformers are used in power generation and transmission networks, while smaller distribution types step down the voltage for residential and commercial use. Instrument units serve a critical role in measurement and protection systems, ensuring the accurate monitoring and safe operation of electrical equipment. Learning about the construction of a transformer highlights how design features such as pressure relief valves and bushings affect explosion risk.

Transformer Oil

Oil plays a critical role in the operation and longevity of these devices. It serves as an insulator, preventing electrical breakdown between the windings, and as a coolant, dissipating the heat generated during operation. Different types of transformer oil are available, including mineral oil, silicone oil, and ester oil, each with its own characteristics and applications.

Transformer Explosion Case Studies

Analyzing real-world case studies of transformer explosions provides valuable insights into their causes and consequences. By examining what went wrong in previous incidents, engineers and operators can learn valuable lessons and implement preventive measures to avoid similar occurrences. These case studies also highlight the importance of proper maintenance, adherence to safety standards, and prompt response to potential issues.

Transformer Standards and Regulations

Various standards and regulations govern the design, installation, and operation of power transformers to ensure safety and reliability. IEEE standards provide comprehensive guidelines for design, testing, and maintenance, while NFPA codes focus on fire safety regulations for electrical equipment. Local regulations may also impose specific requirements for installation, ensuring compliance with regional safety codes.

Transformer Explosion Prevention

Preventing transformer explosions requires a multifaceted approach that encompasses proper installation, regular maintenance, and adherence to safety protocols. Ensuring adequate ventilation and grounding during installation is crucial for preventing overheating and electrical hazards. Following manufacturer recommendations for maintenance, including periodic inspections and oil testing, is essential to identify and address potential issues before they escalate. Implementing overload protection using appropriate fuses and circuit breakers safeguards the unit from excessive current flow.

Transformer Explosion Investigation

When a transformer explosion occurs, a thorough investigation is necessary to determine the root cause and prevent similar incidents in the future. This involves a comprehensive scene assessment to gather evidence and document the damage, followed by data analysis to review operational data and maintenance records. The final step involves a root cause analysis to identify the underlying factors that contributed to the explosion, enabling corrective actions and improvements to safety protocols.

By understanding the various aspects of power transformer explosions, from their causes and effects to prevention and investigation, we can work towards minimizing the risks associated with these critical components of our electrical infrastructure.

Frequently Asked Questions

What causes a power transformer to explode?

Several factors can cause a power transformer to explode, including:

-

Internal faults: Insulation breakdown, short circuits, and overheating.

-

External factors: Lightning strikes, power surges, and animal intrusion.

-

Overloading: Exceeding the unit's capacity.

-

Poor maintenance: Lack of regular inspection and upkeep.

What are the potential hazards of a power transformer explosion?

A power transformer explosion poses several hazards, such as:

-

Power outages: Disruption of the electricity supply.

-

Fires: Release of flammable oil and materials.

-

Environmental damage: Oil spills and the release of toxic gases.

-

Safety hazards: Risk of injury or death to people nearby.

How can a power transformer explosion be prevented or mitigated?

They can be prevented or mitigated through:

-

Regular maintenance and inspection: Including visual checks, oil analysis, and electrical testing.

-

Proper installation: Ensuring adequate ventilation and grounding.

-

Overload protection: Using appropriate fuses and circuit breakers.

-

Safety features: Utilizing pressure relief valves, Buchholz relays, and other protective devices.

-

Adherence to standards and regulations: Following IEEE standards, NFPA codes, and local regulations.

-

Thorough investigation of incidents: Conducting root cause analysis to identify and address contributing factors.

To minimize downtime and hazards following an incident, utilities often rely on power transformer health checks to inform repairs and replacement planning.

Related Articles

Download Our FREE Utility Transformers Handbook

Electrical Transformer Handbook Vol. 3

Thermal overload protection, on-line maintenance, oil-filled and gas operational applications are studied in great detail with all new articles in this 100+ page handbook on Electrical Transformers, Volume 3.

In this edition, we explore a wide range of transformer-related topics, from the selection and specification of transformers for various applications to the latest advancements in transformer design and materials. The handbook delves into the complexities of transformer operation, including load management, voltage regulation, and fault detection, with a focus on optimizing performance and reducing losses. We also provide detailed coverage of transformer testing methods, condition monitoring, and diagnostics, offering practical guidance to help professionals ensure the longevity and reliability of their equipment.

With an emphasis on modern transformer technologies, Volume 3 also covers innovations such as oil-free transformers, compact designs for renewable energy systems, and digital transformer monitoring systems that are transforming how we manage power distribution. The volume also addresses the growing importance of sustainability and energy efficiency, providing strategies for designing transformers that minimize environmental impact while maximizing operational efficiency.

Whether you are involved in the manufacturing, installation, maintenance, or operation of transformers, Electrical Transformer Handbook, Volume 3 serves as an essential resource for enhancing your knowledge and expertise in this critical area of electrical engineering. We hope this volume will empower you to navigate the complexities of transformer systems, ensuring they operate safely, efficiently, and reliably throughout their lifespan.

Latest Utility Transformers Articles

Power Transformers

Power transformers are vital in electrical transmission, stepping voltage up or down between generating stations and substations. These high-capacity devices minimize energy loss, support grid stability, and ensure efficient long-distance electricity distribution.

What are Power Transformers?

Power transformers are large electrical devices designed for high voltage transmission. They efficiently transfer energy across networks, reducing losses and ensuring a reliable supply.

✅ Step up voltage for efficient long-distance transmission

✅ Step down voltage for distribution at substations

✅ Support grid reliability and minimize energy loss

Power transformers are often compared with distribution transformers, which step down voltage for end-user consumption at lower ratings.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Incorporating state-of-the-art technology and innovative design, modern power transformers play a crucial role in transforming electrical voltage from one level or phase to another. With high efficiency and the ability to adapt to various voltage levels, power transformers serve as essential components in electrical distribution systems. This article explores the features and functions of power transformers, emphasizing the importance of air cores, iron cores, load tap changers, oil immersion, and other crucial components. Understanding the construction of a transformer and key transformer components is essential for specifying reliable power transformer designs.

Power transformers are crucial to modern electrical distribution systems. They consist of an array of components, such as air cores, iron cores, load tap changers, oil immersion, and instrument, which work in tandem to ensure high efficiency, adaptability, and safety across various voltage levels. As power distribution networks continue to evolve, state-of-the-art power transformers will remain an integral component in the reliable and efficient transmission of electrical energy. In many utility networks, a substation transformer works alongside large power transformers to regulate voltage levels and maintain grid stability.

Power Transformers vs. Distribution Transformers

| Feature | Power Transformers | Distribution Transformers |

|---|---|---|

| Primary Use | Transmission networks for stepping voltage up or down at generating stations and substations | Distribution networks for delivering usable voltage to commercial, industrial, and residential users |

| Voltage Levels | High voltages (400 kV, 200 kV, 110 kV, 66 kV, 33 kV) | Lower voltages (11 kV, 6.6 kV, 3.3 kV, 440 V, 230 V) |

| Rating | Above 200 MVA | Below 200 MVA |

| Load Variation | Operates close to full load continuously | Operates with variable load demand |

| Efficiency Focus | Minimizes transmission energy losses during long-distance transfer | Prioritizes voltage regulation and reliable end-user supply |

| Size and Location | Large units installed at substations or generating stations | Smaller units mounted on poles, pads, or underground for local distribution |

| Cooling Methods | Oil immersion, advanced cooling, load tap changers | Natural air or oil cooling, simpler design |

| Typical Configurations | Single-phase or three-phase primary configurations | Primarily three-phase or single-phase for local supply |

Power transformers can be configured as either a single-phase primary configuration or a three-phase configuration. Other important aspects to consider when specifying may include:

-

Maximum secondary output voltage rating

-

Maximum secondary current rating

-

Maximum rating

-

Output type

-

Electronic components

-

Primary and secondary windings

Power transformers employ the principle of magnetic induction between coils to convert voltage and current levels. They consist of a wide range of electrical transformers, such as auto, control, current, distribution, general-purpose, instrument, isolation, and potential (voltage). To reduce risks and improve performance, modern units incorporate transformer insulation, transformer oil, and advanced transformer design.

Unlike distribution types, which operate at normal levels, power transformers are typically utilized in electric utility transmission networks that use high voltages for either step-up or step-down applications (400 kV, 200 kV, 110 kV, 66 kV, 33 kV) and are rated higher than 200 MVA. Utility distribution types, on the other hand, work in distribution networks to transform electricity to a level (11 kV, 6.6 kV, 3.3 kV, 440 V, 230 V) suitable for end-user consumption and are rated lower than 200 MVA.

Configurations for power transformers can be either single-phase primary or three-phase, with essential factors such as maximum secondary output voltage rating, maximum secondary current rating, maximum power rating, output type, electronic components, and primary and secondary windings determining their specifications. Operators rely on tools like condition monitoring in an age of modernization and maintenance inspection windows on transformers to keep high-voltage equipment running safely.

The air core and iron core designs of power transformers are integral to their functionality. Air cores generate high-frequency, low-energy magnetic fields, while iron cores are used for their low-frequency, high-energy counterparts. The combination of these two core types allows them to maintain high efficiency and adaptability across various voltage levels.

Load tap changers are another critical component of power transformers. They adjust the transformer's voltage ratio, enabling it to adapt to fluctuating electricity requirements and maintain a stable output. This feature is especially important for medium and high voltage types used in transmission and distribution networks.

Power transformers also benefit from oil immersion, a technique that submerges the transformer's components in insulating oil. This not only cools the transformer but also provides electrical insulation, reducing the risk of short circuits and prolonging the transformer's lifespan. For deeper insight into applications, see our detailed guide on electrical power transformers definition and types, which explores classifications, voltage ranges, and performance factors.

Instrument transformers play a significant role in power transformer systems, as they provide accurate measurements of current and voltage levels for monitoring, control, and protection purposes. These ensure the safe and efficient operation of the electrical distribution network.

Step-up units are a vital component of electrical generation systems, increasing the voltage levels generated by power plants to reduce energy loss during long-distance transmission. Conversely, step-down units reduce high voltage levels to lower, safer levels suitable for end-user consumption.

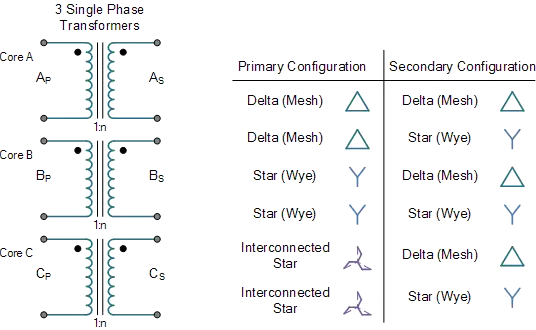

Three Phase Transformer Connections

Three Phase Transformer Connections configure windings in delta or wye to optimize voltage transformation, load balancing, and system reliability in power distribution networks.

What are Three Phase Transformer Connections?

✅ Configure transformer windings in delta, wye, or combinations for specific voltage and load needs.

✅ Improve load balancing, efficiency, and fault tolerance in three-phase systems.

✅ Support reliable power transmission and distribution across networks.

Why Three Phase Transformers Are Preferred

Large blocks of AC power are transmitted and distributed at high voltage levels through three-phase transformer connections. While it’s possible to connect three single-phase transformers to form a three-phase transformer bank, the standard approach is to integrate all three phase windings into a single core. This single-unit design offers:

-

Higher efficiency compared to three separate single-phase units.

-

Simpler busbar, switchgear, and wiring arrangements.

-

Reduced weight and space requirements.

-

Lower manufacturing cost due to reduced core material.

The main advantage of a transformer bank is fault tolerance. If one single-phase transformer in a bank fails, the remaining units can sometimes be reconfigured to provide partial service. In a single three-phase transformer, failure of one winding requires the entire unit to be removed from service. However, modern transformers are highly reliable, making three-phase units the norm. Three-phase distribution systems often rely on utility transformers to step voltage levels up or down for efficient transmission and delivery.

3-phase transformers are essential in power systems for efficiently transmitting and distributing electricity. Depending on the application, they can be built in different configurations, such as a delta transformer connection for robust performance under unbalanced conditions or a star star connected arrangement for providing a neutral point. Inside the unit, an iron core supports the magnetic coupling between windings, allowing precise control of phase voltages across the primary and secondary sides. While designed to supply balanced three-phase loads, these transformers can also serve a single phase load when properly connected. Understanding the various types of three phase transformer designs helps engineers choose the most efficient and reliable option for their specific requirements. Understanding the construction of transformer cores, windings, and insulation is essential when evaluating design and performance.

Fig. 1. Delta-Delta three-phase distribution transformer connection showing primary and secondary windings on a shared core for balanced power delivery.

In many distribution networks, a distribution transformer serves as the final voltage step before electricity reaches the consumer.

Connection Types (Delta-Delta, Wye-Wye, Delta-Wye, Wye-Delta)

Three-phase transformer connections are named according to how the primary and secondary windings are interconnected. For compact installations, a 3 phase pad mounted transformer provides a secure, ground-level solution for neighborhoods and commercial sites.

Delta-Delta (Δ-Δ)

-

No phase shift between primary and secondary.

-

Suitable for systems without a neutral connection.

-

Tolerates unbalanced loads reasonably well.

Wye-Wye (Y-Y)

-

No phase shift, but prone to third-harmonic distortion unless a delta tertiary winding is added.

-

Provides a neutral point for grounding.

Delta-Wye (Δ-Y)

-

Introduces a 30° phase shift between primary and secondary.

-

Secondary side provides a grounded neutral, useful for distribution.

-

Common in utility step-down applications.

Wye-Delta (Y-Δ)

-

Also introduces a 30° phase shift but in the opposite direction to Δ-Y.

-

Suitable for stepping voltage up in transmission systems.

Engineers selecting equipment can review our complete guide to 3 phase transformers to compare ratings, applications, and configurations.

Fig. 2. - Three-phase transformer windings on a laminated core, illustrating primary delta and secondary wye coil arrangements for voltage step-down.

When selecting specialized designs, medium voltage transformers can provide reliable service for industrial and utility applications.

Quick Comparison Table

| Connection Type | Phase Shift | Neutral Availability | Advantages | Limitations |

|---|---|---|---|---|

| Delta-Delta | 0° | No | Handles unbalanced loads well | No neutral |

| Wye-Wye | 0° | Yes | Neutral point for grounding | Harmonic distortion risk |

| Delta-Wye | +30° | Yes (secondary) | Common in step-down, grounded neutral | Phase shift requires attention |

| Wye-Delta | -30° | No | Common in step-up applications | No secondary neutral |

| Open-Delta | Varies | No | Allows temporary service with reduced capacity | Limited output (~58–87%) |

Phase Shift & Vector Groups

Each connection type produces a specific phase displacement between the primary and secondary voltages. This displacement is indicated in vector group notation (e.g., Yd11, Dy1). The first letter denotes the primary winding connection (Y for wye, D for delta), the second denotes the secondary connection, and the number indicates the phase shift in clock notation.

Example: Yd11 means a wye-connected primary, delta-connected secondary, with a 330° displacement (or -30° phase shift).

Fault Tolerance & Open-Delta Configuration

In the event of a single transformer failure in a delta-connected bank, an open-delta (V-V) connection can be used temporarily. This allows the system to continue operating at approximately 58–87% of its original capacity, depending on loading. This method provides short-term service continuity until repairs are made.

Fig. 3. Open-delta three-phase transformer bank created from single-phase units, used for temporary service during transformer faults.

Engineering Best Practices

-

Polarity (Dot Convention): Always observe correct polarity markings when connecting windings to avoid circulating currents or short circuits.

-

Voltage & Impedance Matching: When forming a transformer bank, ensure identical voltage ratings, kVA capacity, impedance, manufacturer, and model.

-

Grounding: For grounded systems, Wye-connected windings with a neutral point are preferred.

-

Balanced Loading: Strive for even load distribution across all phases to prevent overheating and performance degradation.

Visual Referencing

Update figure captions to be descriptive and SEO-friendly:

-

“Delta-Wye Connection Diagram – Showing Primary Delta and Secondary Wye Windings”

-

“Star-Delta Phasor Relationships – Phase Shift Illustration”

-

“Open-Delta Transformer Bank – Temporary Fault Operation”

Related Articles

Reactors In Power System And Its Afffect On Transformer

Reactors in Power System and Its Afffect on Transformer mitigate fault current, damp inrush and transients, add series impedance, reduce harmonics, and enhance voltage regulation for grid stability and transformer protection.

What Are Reactors in Power System and Its Afffect on Transformer?

They limit fault current, curb inrush, add impedance, cut harmonics, improve voltage regulation to protect transformers.

✅ Limit short-circuit currents and transformer stress

✅ Reduce inrush, harmonics, and improve power quality

✅ Enhance voltage regulation and system stability

Reactors in power systems control voltage levels, limit fault currents and improve power quality in utility transformers. These inductive components are strategically installed to manage reactive power, mitigate short-circuit currents, and reduce voltage fluctuations, ensuring the stability and efficiency of the electrical grid. Without reactors, transformers can experience excessive voltage stress, increased losses, and potential damage due to high fault currents. This article explores the function of reactors in power systems, their impact on transformer performance, and why they are essential for maintaining grid reliability and operational safety. Readers looking for fundamentals can review the function of a transformer to see how core principles relate to reactor applications.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Limiting Short Circuit Currents

One of the primary functions of reactors is to limit short-circuit currents. When a fault occurs in the system, excessive current can flow through transformers and other electrical components, causing mechanical and thermal stress. Reactors help manage these currents by introducing reactance, thereby reducing energy losses and preventing catastrophic damage. By doing so, they protect high-voltage transformers from overheating and insulation breakdown, ultimately extending their operational lifespan. Design choices in windings and insulation are outlined in the transformer components overview for context on how reactors mitigate stress.

Voltage Stability and Regulation

Voltage levels and system stability are also closely tied to the use of reactors, including their placement in power grids. Sudden fluctuations in load can lead to voltage instability, which can adversely affect transformers. Reactors help stabilize voltage by counteracting these fluctuations, maintaining consistent voltage transformation across different operating conditions. This ensures that transformers function within safe operating limits, preventing unnecessary strain on their windings and insulation. In substation environments, the role of reactors is coordinated with the electrical substation transformer to maintain steady bus voltages.

Harmonic Filtering

Another crucial aspect of reactors in power systems is their ability to filter harmonics. Harmonics are unwanted distortions in the electrical waveform caused by nonlinear loads, and they can lead to excessive heating and insulation degradation in transformers. By absorbing harmonic currents, reactors minimize these distortions and improve overall power quality. This enhances the efficiency of power transmission and distribution, reducing the risk of transformer failures due to harmonic-related overheating. For a broader context on core design and impedance, see power transformers explained and how filtering complements those characteristics.

Reactive Power Compensation

Reactive power compensation is another important function of reactors in electrical power systems. Transformers rely on a balanced power factor to operate efficiently, and reactors assist by controlling reactive power flow. A poor power factor can lead to increased losses and inefficiencies, but by incorporating reactors, utilities can optimize the performance of power transformers and reactors while reducing energy waste. This contributes to a more stable and cost-effective power grid. In bulk transmission, the interaction between shunt reactors and the power transformer helps maintain acceptable power factors under varying load profiles.

Managing Inrush Currents

Additionally, reactors help manage inrush currents during transformer energization. When a high-voltage transformer is switched on, it can experience a sudden surge of current due to magnetic flux build-up in its core. This inrush current can cause voltage sags and unnecessary stress on transformer windings. Reactors limit this surge by controlling the rate at which magnetic fields develop, protecting transformers from excessive wear and tear while maintaining system stability. Coordinated energization practices are especially important with a distribution-class power transformer to minimize service voltage dips.

Frequently Asked Questions

How do reactors in a power system help protect transformers from short circuits?

Reactors are essential components in power systems that limit short circuit currents, thereby protecting transformers and other equipment from excessive electrical and thermal stress. When a fault occurs, the sudden surge of current can damage transformer windings and insulation. By adding reactance into the circuit, reactors restrict the magnitude of the fault current, preventing catastrophic failures and ensuring that circuit breakers can safely interrupt the fault. This helps maintain system reliability and extends the lifespan of transformers.

What role do reactors play in voltage regulation and system stability?

Voltage fluctuations in power systems can negatively impact transformer performance and overall grid stability. Reactors help regulate voltage levels by controlling reactive power flow, thereby preventing overvoltage conditions during light load periods and mitigating voltage drops during heavy load conditions. By balancing reactive power, reactors contribute to system stability, ensuring transformers operate efficiently and within their designed voltage limits, reducing stress on insulation and core materials.

How do reactors reduce harmonic distortion and improve power quality in transformers?

Harmonics in power systems arise due to nonlinear loads, which generate distorted waveforms. These distortions can lead to increased heating, insulation degradation, and reduced efficiency in transformers. Reactors, particularly harmonic filtering reactors, help absorb or block these unwanted frequencies, preventing excessive current flow through transformer windings. This improves power quality, reduces energy losses, and enhances the reliability of both transformers and the entire electrical network.

Why is reactive power compensation important for transformers, and how do reactors assist in this process?

Reactive power is necessary for maintaining voltage levels and ensuring the efficient operation of transformers. However, an excessive amount of reactive power can lower the power factor, leading to inefficiencies and increased energy losses. Reactors, especially shunt reactors, help absorb excess reactive power, thereby improving the power factor and reducing unnecessary load on transformers. This enhances efficiency, minimizes heating, and helps utilities optimize power transmission and distribution systems.

What are the different types of reactors used in power systems, and how do they impact transformer performance?

There are primarily two types of reactors used in power systems: series reactors and shunt reactors. Series reactors are connected in series with transmission lines or transformer circuits to limit short circuit currents and protect equipment from damage. Shunt reactors, on the other hand, are connected across transmission lines to compensate for reactive power, stabilizing voltage and preventing overvoltage conditions. Both types contribute to improved transformer performance by enhancing protection, maintaining voltage balance, and optimizing energy efficiency.

Reactors in power systems play a crucial role in ensuring the efficient and reliable operation of transformers by controlling fault currents, stabilizing voltage levels, and improving power quality. By limiting short circuit currents, reactors protect transformers from excessive electrical and thermal stress, preventing damage and prolonging their lifespan. They also help maintain voltage stability by managing reactive power, reducing fluctuations that could negatively impact transformer performance. Additionally, reactors mitigate harmonic distortion, improving power quality and reducing energy losses. Whether through series reactors for fault current limitation or shunt reactors for voltage regulation and reactive power compensation, these components are essential for optimizing transformer efficiency and safeguarding the overall electrical grid. Field planners can also assess how reactor strategies scale down to the distribution transformer across feeders and laterals.

Related Articles

Why is Power Conserved in Transformers? Understanding Conservation

Why is power conserved in transformers? Because electromagnetic induction transfers energy with inverse voltage-current ratios, so, in an ideal transformer, P=VI remains constant; real units show high efficiency with copper and core losses.

Why Is Power Conserved in Transformers?

Transformers conserve power: induction trades voltage and current; input equals output plus minor core and copper losses.

✅ Ideal case: P=VI constant; voltage rises as current falls.

✅ Turns ratio sets V and I inversely; impedance reflects across windings.

✅ Real transformers lose power via copper and core losses; high efficiency.

Why is power conserved in transformers? This fundamental principle, underpinned by the law of conservation of energy, is paramount for industrial electricians. Understanding power conservation in equipment is essential for ensuring proper voltage regulation, minimizing energy losses, and optimizing performance in industrial settings. Industrial electricians will learn how the equipment works, the principles behind conservation, and why maintaining an optimal power balance is crucial for safe and efficient operations. This knowledge will help electricians troubleshoot transformer issues, improve energy efficiency, and enhance the longevity of electrical equipment in industrial environments. For a step-by-step refresher on the underlying mechanisms, this guide to how transformers work offers clear context for practical troubleshooting.

Why is Power Conserved in Transformers?

Transformers are essential components in the transmission of electrical energy across long distances, operating under the core principle of the conservation of energy. This principle ensures that the energy entering the transformer is almost entirely transferred to the secondary circuit, with only minimal losses. Understanding why power is conserved in equipment requires a deep dive into how these devices work, specifically through the concepts of electromagnetic induction, voltage and current relationships, and efficiency. The law of conservation of energy plays a key role in how equipment maintains the balance of energy between its primary and secondary coils. In utility and industrial settings, a power transformer is engineered to embody these relationships with high reliability under varying load conditions.

The Conservation of Energy in Transformers

The conservation of energy is a fundamental concept in physics and equipment, it means that the electrical energy entering the primary coil is transformed and delivered to the secondary coil, minus any losses. This is because equipment operates on the principle that energy cannot be created or destroyed. Instead, it is merely converted from one form to another. In the case of a transformer, alternating current flowing through the primary coil generates a magnetic field, which induces an electromotive force (EMF) in the secondary coil. The primary and secondary coils are coupled through this magnetic field, facilitating energy transfer. The electrical energy input is nearly equal to the output, minus minor losses such as heat due to resistance in the wires or magnetic losses in the core. A concise review of transformer components helps connect these energy flows to the roles of cores, windings, and insulation.

Electromagnetic Induction and Energy Transfer

At the heart of transformer operation is the process of electromagnetic induction. According to Faraday's Law of Induction, a change in magnetic flux through a conductor generates an electric current. In equipment, a varying current in the primary coil creates a changing magnetic field that surrounds the coil. This magnetic field then induces a voltage in the secondary coil without the need for a physical connection between the two coils. The ability of equipment to transfer energy efficiently via this magnetic coupling without direct electrical contact is a crucial reason why electricity is conserved. The changing magnetic field allows for the seamless transfer of energy from the primary to the secondary coil, respecting the law of conservation of energy. This same coupling underpins the operation of an electric pole transformer that steps distribution voltages down safely for customers.

The Voltage and Current Relationship

Equipment also maintain energy conservation through the relationship between voltage and current, which is determined by the number of turns in the primary and secondary coils. The turns ratio dictates how the voltage is stepped up or stepped down. When a transformer increases the voltage in the secondary coil, the current is proportionally reduced, and vice versa. This relationship ensures that, despite changes in voltage, the total electricity (the product of voltage and current) remains approximately the same on both sides of the transformer. In essence, if the voltage is increased, the current decreases, which ensures that energy is conserved while still achieving the desired voltage output on the secondary side. Understanding the tradeoff also informs real-world assessments like how much electricity a high-voltage transformer uses during varying load profiles.

Efficiency and Losses

While equipment is highly efficient, some energy is inevitably lost during the transformation process. These losses occur due to resistance in the wires of the primary and secondary coils, as well as magnetic losses in the core. The core material used in the transformer can influence efficiency, as energy can be dissipated in the form of heat when the magnetic field interacts with the core material. However, these losses are relatively small, and modern equipment are designed to minimize them. By carefully selecting materials and optimizing the design, manufacturers ensure that the losses are kept to a minimum, allowing the transformer to operate as efficiently as possible and conserve energy. Technicians often evaluate core magnetizing and stray losses by asking whether transformers use power with no load to benchmark standby performance.

Ideal vs. Real Transformers

An ideal transformer is one in which there are no energy losses, and all the energy from the primary coil is transferred to the secondary coil. This theoretical model helps us understand how energy should be conserved in an ideal scenario. In practice, however, real equipment exhibits small losses, but these are generally negligible in comparison to the total energy transferred. The ideal transformer model serves as a benchmark for evaluating the performance of real equipment, and the design of modern equipment strives to approach this ideal as closely as possible. The law of conservation of energy still holds in real equipment, with the small losses simply representing practical limitations rather than a violation of the fundamental principle.

Frequently Asked Questions

Why is power constant in transformers?

Power remains constant in equipment, with only minimal losses, because of the principle of conservation of energy. Equipment operates by transferring electrical energy from the primary coil to the secondary coil through electromagnetic induction. The input electricity, which is the product of the voltage and current in the primary coil, is nearly equal to the output electricity in the secondary coil. The only difference is the small losses due to resistance in the coils and magnetic losses in the core, but these losses are typically minimal. Therefore, in an ideal transformer, electricity stays constant, as the total energy entering and exiting the transformer remains the same, minus losses.

What is the conservation of energy in a transformer?

The conservation of energy in a transformer refers to the principle that energy cannot be created or destroyed, only converted from one form to another. In a transformer, the energy entering the primary coil (via alternating current) is transferred through a changing magnetic field to the secondary coil. While the energy is converted into a different form (from electrical energy in the primary coil to electrical energy in the secondary coil), the total amount of energy remains nearly the same, except for the small losses that occur due to resistance and core inefficiencies. This ensures that, despite the changes in voltage and current, the energy is conserved throughout the process. For readers new to terminology, this explainer clarifies whether a power supply and a transformer are the same thing and how their roles differ.

Does power stay the same?

Yes, the power in a transformer stays nearly the same, with only slight variations due to inefficiencies. In an ideal transformer, where no losses occur, the electricity on the primary side is equal to the electricity on the secondary side. This relationship is maintained through the equation P=V×IP = V \times IP=V×I (Power = Voltage × Current), where the voltage and current change proportionally based on the turns ratio of the primary and secondary coils. As the voltage is stepped up in the secondary coil, the current decreases in the same proportion, ensuring that the overall power remains constant. In real equipment, small losses due to factors like resistance and core losses cause slight deviations, but the power is still largely conserved.

What is the need for energy conservation?

Energy conservation in equipment is crucial because it ensures that the electrical energy transferred through electricity grids is used as efficiently as possible. Since equipment is used to transmit electrical electricity over long distances, any loss of energy would result in wasted resources and higher operational costs. By conserving energy, equipment helps reduce energy waste, making electricity distribution more efficient and cost-effective. The principle of energy conservation also supports the design of equipment to minimize losses, which allows for more efficient power transmission, reduces energy costs, and contributes to the overall sustainability of electrical systems.

Why is power conserved in transformers? It's an important question. Power is conserved in equipment due to the principle of energy conservation. A transformer works by transferring electrical energy between two circuits through electromagnetic induction, typically changing voltage levels while maintaining the total electricity. The primary coil receives electrical energy and creates a magnetic field, which induces a current in the secondary coil. The key factor in electricity conservation is that, in an ideal transformer, the power input (voltage × current) on the primary side equals the electricity output on the secondary side, minus any losses like heat. This means that any increase in voltage on the secondary side results in a proportional decrease in current, and vice versa, ensuring that power remains conserved across the system.

Related Articles

Power Transformers

Power transformers step up or down the voltage in transmission networks. Built with laminated cores, copper windings, and insulation, they ensure efficiency, regulate current, and deliver stable electricity for utility, industrial, and substation applications.

What are Power Transformers?

Power transformers are high-voltage electrical devices that transfer energy between circuits using electromagnetic induction, ensuring efficient transmission and distribution.

✅ Convert voltage for long-distance transmission and local distribution

✅ Use laminated cores, copper windings, and dielectric insulation for efficiency

✅ Essential in substations, industrial plants, and utility power grids

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Power Transformers – Definition, Construction, and Role in the Grid

Power transformers are the heavy lifters of the grid. They step the voltage up for efficient long-distance transmission and step it down so power can be delivered safely to regional networks. Built around laminated steel cores, copper or aluminum windings, and robust insulation systems, these high-voltage machines minimize losses, stabilize voltage, and ensure the continued operation of industrial, commercial, and utility systems. For background on the science behind energy transfer, see our guide on how do transformers work.

A power transformer transfers energy between circuits through electromagnetic induction, using a magnetic core and tightly engineered windings to change voltage without altering frequency. Unlike distribution units (optimized for continuous partial load), power transformers typically operate near full load and at very high voltages for bulk power flow. In generating stations, they step up generator output to transmission levels; at the grid edge, they step down for regional networks and hand off to distribution equipment inside an Electrical Substation Transformer. In short, power transformers do the heavy lifting, allowing distribution transformers to safely complete the job.

Role in the Electrical Grid

Every stage of the power system depends on transformers designed for specific functions.

-

Generation → Transmission: Step-Up Transformers raise voltage (and lower current) so power can travel hundreds of kilometres with reduced line losses.

-

Transmission Backbone: High Voltage Transformers at 230 kV, 400 kV, and beyond move bulk energy between regions.

-

Regional Handoffs: Substation Transformers adapt voltage for local grids and industrial corridors.

-

Final Delivery: Distribution Transformers reduce voltage to service levels, using formats that match the environment—PadMount Transformer for urban vaults and campuses, Pole Mounted Transformers for overhead rural lines, and Underground for dense city cores.

Types of Power Transformers

Different designs solve different problems—what changes is the voltage, location, and duty:

-

Step-Up / Step-Down: The classic grid pair. Step up at the plant, step down near load centers. (See Step-Up Transformers.)

-

Three-Phase Units: The utility standard for efficiency and footprint, with connection options covered in 3 Phase Transformers.

-

Autotransformers: Shared-winding designs that save copper and losses when only modest voltage change is required—see What Is an Autotransformer.

-

Medium-Voltage / High-Voltage: Secondary substations and industrial feeders lean on Medium Voltage Transformers, while long-haul corridors depend on High Voltage Transformers.

-

Line-Mounted: For specific corridors or taps, utilities use Powerline Transformers.

All of these sit within your broader Utility Transformers ecosystem.

Design and Construction

The performance and reliability of a power transformer depend on precise design.

-

Core – Built from laminated silicon steel to guide magnetic flux and reduce losses. See our page on the transformer core.

-

Windings – Copper or aluminum coils wrapped around the core; winding design determines voltage ratios. Learn more about transformer windings.

-

Insulation – Oil, resin, or specialized paper prevents electrical shorts and overheating. Details at transformer insulation.

-

Cooling Systems – Transformer oil provides both cooling and dielectric strength; large units use pumps and radiators.

-

Components – Bushings, tap changers, and other transformer components adapt units to load conditions and protect against surges.

To explore assembly methods, refer to our guide on the construction of a transformer.

Efficiency and Energy Losses

Transformers are designed to minimize wasted energy, but two types of losses remain:

-

No-load losses – Core losses caused by hysteresis and eddy currents when energized.

-

Load losses – Resistance in windings, eddy currents, and stray flux during operation.

Because power transformers typically operate near their design point, they achieve very high efficiencies, whereas distribution units—optimized for 24/7 availability—reach peak efficiency at partial load. Oil management and cooling design are central—see Transformer Oil—as are proper Transformer Overcurrent Protection strategies.

Testing, Monitoring, and Reliability

Before service, transformers undergo rigorous validation, including dielectric (high-potential/impulse/induced), polarity, and ratio checks, temperature rise, and load/no-load measurements. In operation, continuous condition awareness is the goal. Hydrogen Detection Systems and Hydrogen Leak Detectors flag incipient faults. Maintenance Inspection Windows enable targeted inspections. Broader analytics are covered in Condition Monitoring in an Age of Modernization. Many operators consolidate this into a Power Transformers Health Check to prioritize interventions.

Applications in Electricity Distribution

Power transformers appear in nearly every part of the grid:

-

Generating plants use step-up units to prepare electricity for transmission.

-

Transmission lines depend on high-voltage transformers to minimize losses.

-

Regional substations adjust voltages for communities and industries.

-

Industrial facilities use transformers to power motors, drives, and heavy equipment.

-

Renewable energy systems rely on transformers to connect wind and solar farms.

Supporting technologies, such as voltage transformers and grounding transformers, enhance stability, measurement, and safety in these networks.

Sizing, Protection, and Connections (Quick Guidance)

Specifying a unit involves aligning kV/kVA, impedance, and connections with the grid's needs. Connection choice (delta/wye, vector groups) affects harmonics, grounding, and paralleling. Early scoping often references Typical Transformer Sizes and application-level topics, such as what causes voltage to Be Induced in a Transformer or what is the Function of a Transformer. For AC fundamentals, see AC Transformer; for practical integration work, Wiring a Transformer helps ground the details. Supplier research can start with Transformer Manufacturers.

Maintenance and Reliability

Regular maintenance ensures transformers operate safely and efficiently for decades.

-

Oil testing checks dielectric strength and moisture content.

-

Thermal imaging identifies hot spots in cores and windings.

-

Winding resistance checks detect imbalances or degradation.

-

Visual inspections catch leaks or insulation breakdowns.

Many utilities employ structured programs like a power transformers health check to avoid unexpected failures.

History of Power Transformers

The principle of induction was discovered in the 1830s, laying the foundation for transformers. By the 1880s, practical transformer designs emerged, and by the 1950s, units rated at 400 kV were in service. By the 1970s, single-unit ratings reached 1100 MVA, with 800 kV and higher units appearing in the 1980s. Today, power transformers continue to evolve, integrating digital monitoring and smart grid technologies.

Frequently Asked Questions

What is a power transformer and how does it work?

It is a device that transfers electricity between circuits using electromagnetic induction, stepping voltage up or down for efficient transmission and safe distribution.

How are power transformers different from distribution transformers?

Power transformers handle high voltages and operate near full load, while distribution transformers manage lower voltages and run 24/7 at partial loads.

What are the main components of a power transformer?

Core, windings, insulation, tap changer, bushings — each ensures efficient and safe voltage conversion.

Why is regular maintenance important?

Insulation, windings, and oil degrade over time. Preventive testing and inspections avoid costly failures and keep systems reliable.

Power transformers are the backbone of the electricity delivery system. From stepping up generator output to managing high-voltage transmission and stepping it down again for local use, they enable safe and efficient energy transfer across continents. With strong construction, modern monitoring, and regular maintenance, they remain indispensable to both traditional utilities and the smart grids of the future.

Related Articles

Autotransformer - The Efficiency and Versatility of Technology

Autotransformer offers single-winding voltage regulation with tap changer for efficient step-up or step-down control, ideal for motor starting, soft start, and power distribution where compact design and reduced copper losses matter.

What Is an Autotransformer?

An autotransformer uses a single winding to raise or lower voltage, improving efficiency but without galvanic isolation.

✅ Single-winding design with adjustable taps for voltage control

✅ Step-up or step-down; ideal for motor starting and power distribution

✅ Higher efficiency and lower copper use; no isolation between circuits

Autotransformer technology is a cornerstone for industrial electricians aiming to optimize energy efficiency and ensure smooth operation in complex electrical systems. Understanding how autotransformers work is crucial, as they provide cost-effective voltage regulation, reduce energy losses, and offer flexibility in handling various industrial applications. An autotransformer is a unique type of transformer that operates using a single winding. Unlike traditional transformers with separate primary and secondary windings, the autotransformer utilizes a single coil with a tap point that determines the voltage adjustment. This design allows it to function efficiently by sharing parts of the same winding for both the input and output. The simplicity of its construction reduces material costs, making it a cost-effective solution in many applications. This fundamental structure difference sets the autotransformer apart from its conventional counterparts, offering a streamlined approach to voltage transformation while maintaining reliability and efficiency. For foundational definitions and diagrams, consult this overview of autotransformers to reinforce core concepts.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Operation and Voltage Adjustment

The primary function of an autotransformer is to adjust voltage levels, either stepping up or down the voltage as needed. This is achieved by selecting different points along the winding to act as the tap for the output voltage. For instance, a lower tap point will reduce the output voltage, while a higher one will increase it. This ability to modify voltage levels with precision makes the autotransformer a versatile tool in electrical engineering. Whether used in power distribution systems, industrial machinery, or household appliances, its operational flexibility ensures compatibility with various voltage requirements, enhancing its applicability in diverse scenarios. For a side-by-side comparison of conventional transformers and autotransformers, see this comparison of transformers and autotransformers which clarifies selection criteria for engineers.

Applications

Autotransformers have a wide range of practical applications across different industries. In power distribution systems, they are often employed for voltage regulation, ensuring stable and efficient electricity delivery to homes and businesses. In industrial settings, they adapt machinery to operate with varying voltage supplies, optimizing performance and reducing energy waste. Additionally, they play a crucial role in audio systems, where they are used for impedance matching to improve sound quality. This versatility, combined with their cost-effectiveness, makes devices indispensable in both everyday and specialized electrical applications. Their adaptability to numerous tasks underscores their importance in modern electrical infrastructure. In utility and industrial grids, understanding the role of power transformers helps contextualize where autotransformers fit within overall system design.

Advantages and Disadvantages

One of the most notable advantages of the autotransformer is its compact size and lightweight design. By eliminating the need for separate primary and secondary windings, it requires less material, which not only reduces its size but also lowers production costs. This makes it an attractive option for projects with budget or space constraints. However, the device does come with certain limitations, most notably the lack of electrical isolation between the input and output. This means that any fault on the primary side can directly affect the secondary side, posing potential safety risks in specific scenarios. Understanding these trade-offs is crucial for determining the suitability of an autotransformer in any given application. Where isolation or only minor voltage correction is needed, buck-boost transformers may be preferable in certain installations.

Variable Autotransformers

Variable autotransformers represent a specialized category of these devices, offering an additional layer of functionality. Equipped with a sliding brush mechanism, they allow for continuous adjustment of the output voltage, providing smooth and precise control over voltage levels. This feature is particularly beneficial in applications where fine-tuned voltage regulation is essential, such as in laboratory settings or in testing equipment. The ability to dynamically modify voltage output not only enhances operational flexibility but also increases the range of possible applications. Variable autotransformers exemplify the innovative potential of this technology, further broadening its utility in modern electrical systems. Their operation still follows core AC transformer principles regarding magnetic induction and sinusoidal excitation.

Frequently Asked Questions

What is an autotransformer used for?

An autotransformer is widely used for voltage regulation and conversion in electrical systems, making it an essential tool in various applications. Its design allows for precise adjustments to voltage levels, ensuring stable power delivery even when supply voltages fluctuate. This capability is particularly valuable in industrial and laboratory environments where consistent voltage is critical. Additionally, devices are employed to step up or step down voltages for specific uses, such as powering equipment with differing voltage requirements or optimizing energy transfer in power distribution systems. They also play a crucial role in split-phase systems, balancing voltages between phases to enhance system efficiency. In motor applications, devices serve as starters, reducing initial voltage to minimize power surges and wear on machinery. Their efficiency, compact size, and versatility make them indispensable in modern electrical networks. In systems dealing with direct current, review how DC power transformers are addressed and where alternative conversion methods are applied.

Why do we use autotransformers?

Autotransformers are used because of their efficiency, compact design, and cost-effectiveness in voltage regulation and conversion applications. Their unique single-winding construction allows for reduced material usage compared to traditional transformers, making them lighter, smaller, and more economical. This design also minimizes energy losses, leading to higher operational efficiency. Autotransformers are particularly advantageous when there is a small difference between input and output voltage levels, as their design maximizes energy transfer under these conditions.

They are commonly used for stabilizing fluctuating supply voltages, stepping voltage levels up or down, and balancing voltages in split-phase systems. In motor applications, they act as effective starters by initially reducing voltage to prevent power surges and equipment stress. Their ability to provide continuously variable voltage output through tap points adds to their versatility, making them essential in industries and systems requiring precise voltage control. Overall, autotransformers combine practicality, adaptability, and efficiency, making them a preferred choice in many electrical applications.

What are the three advantages of autotransformers?

Autotransformers offer several advantages that make them a preferred choice in many applications. Here are three key benefits:

- Higher Efficiency: Since autotransformers use a single winding shared between the primary and secondary circuits, they experience fewer energy losses compared to traditional transformers. This makes them more efficient, especially when the voltage difference between input and output is minimal.

- Compact Design and Cost-Effectiveness: The single-winding design requires less material, resulting in a smaller, lighter, and more economical device. This compact size makes autotransformers ideal for applications where space and cost constraints are critical.

- Continuously Variable Voltage Output: With strategically placed tap points, auto transformer can provide precise primary voltage and secondary voltage adjustments. This versatility makes them highly useful in applications that require fine-tuned voltage control, such as laboratory equipment, industrial machinery, and power distribution systems.

These advantages make autotransformers a practical and efficient solution for voltage regulation and conversion in various electrical systems.

What are the two types of autotransformers?

There are two main types of autotransformers: step-up and step-down. A step-up autotransformer increases the voltage on the secondary side relative to the primary side, making it suitable for applications where voltage needs to be boosted, such as in long-distance power transmission or for machinery requiring higher voltage than the input supply. On the other hand, a step-down autotransformer reduces the voltage on the secondary side compared to the primary, commonly used when a lower voltage is needed for devices or equipment, such as household appliances or machinery that operates on a lower voltage than the main supply. Both types leverage a single winding to efficiently convert voltage, offering compact size, cost savings, and improved performance for specific voltage requirements. For broader fundamentals on step-up and step-down transformers, see typical use cases and sizing practices.

An autotransformer is an efficient electrical device used for voltage regulation and conversion. Unlike traditional transformers, which have separate primary and secondary windings, an autotransformer uses a single winding shared between both circuits, making it more compact, cost-effective, and energy-efficient. It is commonly used to either step up or step down voltage levels in various applications, such as industrial machinery, power distribution, and motor starting. The ability to provide continuously variable voltage through tap points makes it a versatile tool for precise voltage control. However, its lack of electrical isolation between primary and secondary circuits limits its use in certain applications where safety is a concern. Despite this, the autotransformer remains an essential component in electrical systems that require efficient voltage regulation with minimal material use and space.

Related Articles

Utility Transformers News

Utility Transformers Media

Utility Transformers Articles From ET Magazine

The Role of Transformer Oil Alternatives in Improving Safety and Environmental Sustainability

The Growing Need for Safer and Greener Transformer Oils

Transformer oil plays a vital role in the operation and longevity of power transformers, providing insulation, cooling, and arc suppression. Traditionally, mineral oil has been the industry standard due to its effective dielectric properties and cost-efficiency. However, growing concerns about fire safety, environmental impact, and sustainability have driven the search for alternative transformer oils. Synthetic esters, natural esters (vegetable-based oils), and silicone fluids are emerging as viable substitutes, offering enhanced fire resistance and biodegradability while maintaining reliable performance. As utilities transition to greener and safer solutions, the role of transformer oil alternatives is becoming increasingly important in ensuring a more resilient and sustainable energy infrastructure.

Limitations of Traditional Mineral Oil

While mineral oil has been widely used for decades, it presents several significant drawbacks. One of the primary concerns is its flammability. Mineral oil has a relatively low fire point, making transformers susceptible to fire hazards, particularly in densely populated areas or critical infrastructure locations. Additionally, in the event of a spill or leakage, mineral oil poses environmental risks due to its slow biodegradation and potential for soil and water contamination. Regulatory agencies and environmental organizations are tightening restrictions on the disposal and handling of mineral oil, pushing utilities to explore safer alternatives.

Another challenge associated with mineral oil is its inability to handle high thermal stress over long periods. As transformers operate under increased loads due to rising energy demands, the thermal stability of insulation fluids becomes a key factor in extending equipment lifespan. Given these limitations, the industry is gradually shifting toward synthetic and natural ester-based alternatives that provide superior fire safety and environmental benefits.

Read the full article in the Transformer Technologies Special Edition

Enhancing Transformer Resilience: Fire Barriers and Safety Measures in Modern Substations

The Growing Concern of Transformer Fire Risks

An Electrical Substation Transformer is a critical component of modern substations, playing a vital role in the transmission and distribution of electricity. However, due to the high-voltage operations, flammable insulation materials, and exposure to extreme weather conditions, transformers are at significant risk of fire and explosions. A solid foundation for transformer safety starts with thoughtful electrical substation design, ensuring layout and equipment placement mitigate fire risk. The consequences of transformer fires can be severe, leading to equipment damage, power outages, environmental hazards, and, in some cases, loss of life. As utilities expand their grids and integrate renewable energy sources, the need to enhance transformer resilience against fire hazards has become more pressing than ever. Proper substation grounding protocols protect transformers and personnel from electrical faults and fire-related events.

Implementing fire barriers and adopting advanced safety measures are crucial to mitigating risks and ensuring an uninterrupted power supply. Understanding the causes and impacts of a substation explosion is essential to improving overall infrastructure resilience.

Causes of Transformer Fires and Explosions

Transformer fires are typically caused by insulation failure, short circuits, overheating, or external environmental factors such as lightning strikes. One of the primary causes is the degradation of transformer insulating oil, which can break down under high temperatures, producing flammable gases that increase the risk of ignition. Electrical arcing, caused by insulation breakdown or mechanical faults, generates extreme heat that can lead to explosions. Robust substation protection systems are critical in isolating faults and minimizing fire propagation.

Overloading transformers beyond their design capacity also contributes to excessive heating, accelerating insulation failure and increasing fire risks. External impacts, such as earthquakes, vandalism, or accidental collisions, can sometimes trigger catastrophic failures.

Read our What is a Substation article for a deeper understanding of substation technology. Consistent electrical substation maintenance is the key to identifying potential hazards before they lead to costly failures.

You can also visit our Substation Maintenance training course.

Visit our Electricity Forum Electrical Substation Channel Page.

Read the full article in the Transformer Technologies Special Edition

Navigating the Transformer Supply Crunch: Strategies for Utilities Amidst Global Shortages

The Growing Transformer Supply Crisis

The global transformer supply chain is facing unprecedented challenges, with utilities worldwide struggling to procure essential equipment due to material shortages, manufacturing delays, and logistical constraints. Transformers are the backbone of electrical transmission and distribution networks, and their scarcity poses significant risks to grid reliability, infrastructure expansion, and system resilience. As demand continues to outpace supply, utilities must adopt strategic approaches to mitigate risks, ensure the timely acquisition of transformers, and maintain operational stability.

Factors Driving the Transformer Shortage

Several factors contribute to the current transformer supply crunch. Raw material shortages, particularly of electrical steel, copper, aluminum, and insulating oils, have led to significant procurement challenges. Electrical steel, essential for transformer cores, has experienced price volatility due to rising global demand and production limitations. Manufacturing bottlenecks have further exacerbated the issue, with many transformer manufacturers operating at full capacity, constrained by workforce shortages and aging production facilities. Lead times for large power transformers, which once averaged 12 to 18 months, have now extended well beyond two years in some cases.

Geopolitical tensions and trade challenges have also played a role in disrupting supply chains. Tariffs, export restrictions, and geopolitical conflicts have made it difficult for utilities to source transformers from traditional suppliers, leading to increased costs and uncertainty. Meanwhile, the global push for electrification, renewable energy integration, and grid modernization has driven demand to unprecedented levels, placing additional strain on an already fragile supply chain. Logistical constraints, including shipping delays, container shortages, and port congestion, have further hindered the timely delivery of transformers, compounding the issue.

Read the full article in the Transformer Technologies Special Edition

MITIGATING TRANSFORMER FAILURES: ADVANCED MONITORING AND MAINTENANCE STRATEGIES

Power transformers are critical assets in electrical transmission and distribution networks. Their failure can lead to widespread outages, costly downtime, and potential safety hazards. As transformers age and operate under varying electrical and environmental stresses, degradation becomes inevitable. However, through advanced monitoring techniques like Dissolved Gas Analysis (DGA) and Frequency Response Analysis (FRA), utilities can proactively identify early signs of failure, enabling preventive maintenance and extending transformer service life.

Dissolved Gas Analysis (DGA): A Window into Transformer Health

DGA is a well-established diagnostic method used to detect transformer insulation and oil degradation by analyzing the gases dissolved in transformer oil. When internal faults occur, electrical and thermal stresses break down the oil and solid insulation materials, generating gases that dissolve in the oil. By examining the composition and concentration of these gases, engineers can infer the nature and severity of the developing faults.

The primary gases analyzed in DGA provide insights into different fault conditions:

- Hydrogen (H₂) indicates low-energy partial discharge activity

Methane (CH₄) suggests overheating of oil at moderate temperatures. - Ethane (C₂H₆) and Ethylene (C₂H₄) signify thermal degradation of oil at high temperatures.

- Acetylene (C₂H₂) is strongly associated with arcing and electrical breakdowns.

- Carbon Monoxide (CO) and Carbon Dioxide (CO₂) indicate degradation of cellulose-based insulation, such as paper and pressboard.

Read the full article in the Transformer Technologies Special Edition

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue